Ultimate Guide to EV Battery Thermal Strategies

How to keep EV batteries between 15°C and 35°C using cooling, heating, preconditioning and telematics to extend range and battery life.

Electric vehicle (EV) batteries work best between 15°C and 35°C. Outside this range, performance drops, lifespan shortens, and safety risks increase. For fleet managers, managing these temperatures is essential to avoid reduced range, frequent charging, or long-term damage. Here's what you need to know:

- Cold Weather: At –10°C, range can drop by 30–45%, and heating systems consume up to 55% of energy. Solutions include preconditioning, heat pumps, and parking in covered spaces.

- Hot Weather: High temperatures accelerate battery degradation. Liquid cooling, hybrid systems, and keeping batteries below 35°C help prevent overheating.

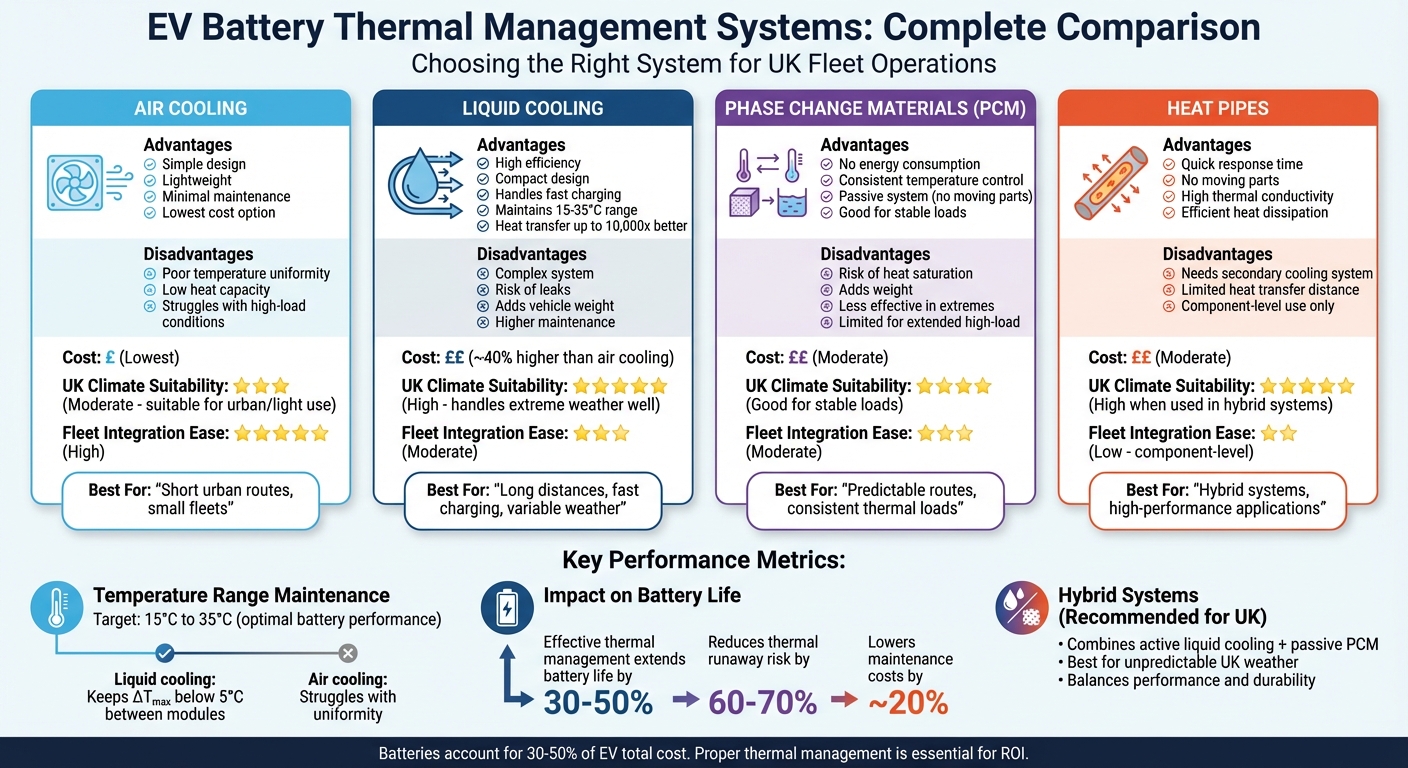

- Thermal Management Systems (BTMS): Air cooling is simple but less effective for heavy use. Liquid cooling and advanced systems like phase change materials (PCM) offer better temperature control but come with higher costs.

- Fleet Insights: Telematics systems track battery health, optimise routes, and prevent thermal issues, reducing downtime and maintenance costs.

Effective thermal management extends battery life by up to 50%, lowers costs, and ensures consistent fleet performance throughout the year.

EV Thermal Management: Heat, Cooling and Charge Efficiency

Why Temperature Control Matters for EV Fleets

Temperature extremes can significantly impact the performance, reliability, and costs of operating electric vehicle (EV) fleets. For example, at −10°C, a van's range can drop from 330 km to just 200–230 km - a reduction of 30–45%. This can wreak havoc on tight schedules, leading to costly mid-route charging stops and service delays.

Cold weather also increases energy consumption dramatically. At −10°C, heating both the cabin and the battery can account for 35% to 55% of a vehicle’s total energy use on urban routes. A small hatchback that typically uses 13–15 kWh/100 km for driving may need an additional 7–9 kWh/100 km just to maintain warmth. One Nordic ride-hailing fleet of 120 electric sedans saw their winter energy consumption jump to 27–30 kWh/100 km, compared to 17–19 kWh/100 km in summer. By introducing mandatory preconditioning and staggered DC fast-charging, they managed to cut unplanned out-of-service events by 40%.

High temperatures bring their own challenges, primarily by accelerating long-term battery degradation. Unlike cold weather, which temporarily reduces range, prolonged exposure to heat can permanently damage battery cells, shortening their lifespan. This makes effective thermal management essential - not just for maintaining performance, but for ensuring the battery pack lasts as long as intended, avoiding costly early replacements.

Charging infrastructure also struggles under extreme temperatures. In winter, DC fast-charging frequency can increase by 30% to 60% per 10,000 km. Cold batteries charge more slowly because their management systems limit power to protect the cells, resulting in longer downtimes when fleet availability is most critical. A European parcel delivery operator with 80 electric vans tackled this issue by redesigning routes to focus on shorter, denser clusters during the coldest days. This strategy allowed depot-only charging to cover 95% of their operations.

For UK fleet managers, who must contend with Scotland’s freezing mornings and summer heatwaves exceeding 30°C, temperature control is a make-or-break factor. Poor thermal management leads to more frequent charging, reduced range, faster battery wear, and higher overall costs. Up next, we’ll dive into the technologies that help maintain optimal battery temperatures under these challenging conditions.

Core Thermal Management Techniques

Electric vehicles rely on three main methods to regulate battery temperatures: air, liquid, and advanced cooling systems. The choice of system depends on factors like vehicle range, charging speed, and the thermal demands of daily use. Let’s start with air cooling, the simplest of these methods.

Air Cooling Systems

Air cooling uses fans or natural airflow to remove heat from battery cells. It’s the most straightforward and cost-effective solution, making it ideal for smaller fleets operating on short, urban routes where heat generation is minimal. However, since air has low thermal conductivity, these systems often struggle to maintain even temperatures across larger battery packs. Research shows that switching from a 'Z-shaped' to a 'J-shaped' channel design can reduce peak temperature increases by up to 31.1%. Still, air cooling falls short when dealing with high thermal loads, such as during rapid DC charging or extended motorway drives.

For situations requiring more effective heat management, liquid cooling is the next step.

Liquid Cooling Systems

Liquid cooling circulates a water-ethylene glycol mixture through cold plates or channels that come into contact with battery modules. Liquids, with their superior thermal conductivity and heat capacity, offer significantly better heat dissipation than air. For instance, single-phase immersion cooling, where cells are submerged in a dielectric fluid, can improve heat transfer by up to 1,000 times compared to air cooling. Two-phase immersion systems take this even further, enhancing heat transfer rates by up to 10,000 times. However, these systems require pumps, valves, and radiators to function, which adds weight and increases installation and maintenance costs. Despite these challenges, liquid cooling is essential for vehicles managing long distances or ultra-fast charging, as it keeps battery cells below 35°C and ensures temperature differences between modules remain within 5°C.

Advanced Cooling Technologies

Innovative techniques like Phase Change Materials (PCM) and heat pipes offer even greater thermal stability. PCMs absorb and store large amounts of heat during their melting process, helping to regulate battery temperatures without consuming additional energy. Heat pipes, on the other hand, use phase-change heat transfer to quickly move heat away from hotspots. These technologies are often combined into hybrid systems, integrating active liquid cooling with passive PCM layers for enhanced performance. Such configurations are particularly beneficial for high-performance fleets, as they can extend battery life by 30% to 40% and lower the risk of thermal runaway by 60% to 70%.

Heating Strategies for Cold Weather

Keeping fleets operational during the UK's chilly winters requires effective heating strategies. While earlier discussions centred on cooling systems, this section dives into warming solutions essential for colder climates. Low temperatures slow down battery chemistry, reducing available power and demanding extra energy for cabin heating. For instance, at –9°C, electric vehicles (EVs) can lose around 25% of their driving range when travelling at 70 mph compared to milder conditions. Below are some key methods to combat cold-weather challenges and protect battery performance.

Resistive Heating

Resistive heating works by converting electrical energy into heat, but it comes at a cost - it draws directly from the battery, significantly cutting into winter driving range. As Consumer Reports explains:

"An EV can't tap its motor's heat to warm the interior. Instead, EVs must tap their batteries to provide cabin heat, which can sap their range".

For fleet managers, one practical workaround is encouraging drivers to rely on heated seats and steering wheels. These options use far less energy compared to heating the entire cabin, helping to conserve battery power.

Heat Pump Systems

Heat pump systems are a more energy-efficient alternative to resistive heating. They extract ambient heat from the outside air - even in freezing conditions - and transfer it into the cabin and battery. Unlike resistive systems that consume battery energy to generate heat, heat pumps simply move existing heat, preserving more battery capacity for driving.

In January 2024, Kia announced that its latest EV models feature advanced heat pumps designed to maximise driving range in cold weather. Similarly, research from Recurrent highlights the Acura ZDX and Volvo EX40 as examples of vehicles utilising this technology. The Zero Emission Transportation Association further notes:

"newer EVs have heat pumps and better battery encasements that can help improve battery efficiency".

Studies indicate that heat pump systems can enhance low-temperature driving range by 5.6% to 23.2%.

Battery Preconditioning

Battery preconditioning involves warming the battery to its optimal temperature before driving or charging, typically requiring 30–45 minutes in freezing conditions. A major benefit of preconditioning is that when it's done while the vehicle is plugged into a charger, it uses grid power instead of draining the battery. This not only conserves energy but also prevents lithium plating, which can cause permanent capacity loss.

Fleet managers can take advantage of scheduled departure features available through vehicle apps. These allow both the battery and cabin to warm up using mains electricity while the EV remains plugged in overnight. This is particularly important as lithium-ion batteries can lose 10% to 40% of their capacity at –10°C, making preconditioning crucial for extending battery life and maintaining performance.

Seasonal Thermal Management Strategies

The UK's unpredictable weather makes year-round thermal management for EV batteries a necessity. Adjusting strategies seasonally not only helps maintain driving range but also extends battery lifespan. UK regulations even mandate manufacturers to design cooling methods suited to local conditions, aiming to minimise battery wear. Seasonal approaches build on general cooling and heating techniques, adapting them to the UK's ever-changing climate.

Managing Summer Heat

Summer brings its own set of challenges, especially when temperatures climb past 35°C. Such heat puts EV batteries under strain, making it crucial to adapt. For instance, keeping the State of Charge (SoC) at around 80% can lower the risk of overheating, as fully charged batteries tend to generate more internal heat. Parking in shaded areas and opting for slower charging speeds are additional steps to reduce heat buildup. This is particularly important for fleets with air-cooled systems, which are less efficient at managing heat and require stricter adherence to these measures.

Technology can also play a role. Fleet telematics systems, like those offered by GRS Fleet Telematics, allow remote activation of cooling systems while vehicles are plugged in. This ensures the cooling process uses grid power instead of draining the battery, preserving range. Finally, smooth driving habits - such as gradual acceleration and gentle braking - help minimise the internal heat generated during operation.

Winter Protection Tactics

While British winters are relatively mild compared to harsher climates, temperatures ranging from 0°C to 5°C still challenge EV batteries. At –10°C, lithium-ion batteries can lose between 10% and 40% of their capacity, with cabin heating accounting for roughly half of winter range loss. To combat this, several strategies come into play. Battery preconditioning, heat pump systems, and zonal heating are all effective ways to maintain battery performance in colder weather. Additionally, parking vehicles in covered or indoor spaces overnight can shield them from sudden temperature drops.

Fleet telematics systems offer another layer of protection by allowing real-time monitoring of key performance indicators. This helps identify vehicles experiencing thermal stress, ensuring efficiency isn't compromised.

Standby Thermal Management

Even when vehicles are idle, maintaining a minimum "floor" temperature is critical to prevent capacity loss and ensure batteries are ready for charging. Keeping EVs plugged in during downtime allows the Battery Thermal Management System to draw power from the grid rather than the battery itself, conserving energy.

Combining active liquid cooling with passive phase change materials (PCM) offers another solution, providing consistent thermal regulation even during rapid weather changes - a frequent occurrence in the UK. Hybrid systems that integrate both methods offer robust protection against both summer heat and winter cold, though they come with added complexity and costs. Continuous monitoring during idle periods remains key to maintaining peak battery performance, no matter the season.

Integrating Thermal Analytics with Fleet Telematics

Once a solid Battery Thermal Management System (BTMS) is in place, integrating telematics takes thermal control to the next level by providing actionable insights. Modern telematics systems capture key EV data like State of Charge (SoC), State of Health (SoH), and temperature, enabling proactive management. This level of detail helps fleet managers identify internal cell reactions or electrical behaviours that could potentially lead to safety risks, such as thermal runaway.

But the benefits don’t stop at safety. By combining battery metrics with live fleet data, these platforms allow managers to visualise thermal performance and estimate battery lifespan. For example, a study by Geotab involving 6,300 EVs across 64 models revealed an average annual battery capacity loss of 2.3% and found that maintaining an optimal operating temperature of 21°C is crucial. This research led to the creation of their "Temperature Tool for EV Range", which helps fleet managers predict how weather conditions affect specific vehicle models.

"Battery lifetime prediction answers some of the most pressing questions in e-mobility: current state of health, effects of usage and remaining useful battery life." - Alwin Tuschkan, Project Manager IODP, AVL

Advanced analytics further enhance maintenance strategies by predicting potential drivetrain or battery issues before they result in downtime. These systems account for variables like seasonal changes, ambient temperature, weather, and even elevation to provide accurate battery range estimates. With the integration of AI and machine learning, platforms such as GRS Fleet Telematics offer deeper insights into how driving behaviours influence battery health. The adoption of 5G connectivity ensures that real-time data tracking remains consistent, even for fleets on the move. This seamless integration of telematics with BTMS allows for precise maintenance and operational adjustments, bridging the gap between thermal management and fleet operations.

Real-Time Temperature Monitoring

Real-time monitoring plays a critical role in maintaining battery temperatures within safe limits. Telematics systems use Controller Area Network (CAN) data at high frequencies - over 5 Hz - to track rapid changes in power and temperature. This allows fleet managers to quickly identify when batteries deviate from the optimal operating range of 15°C to 35°C .

The advantages are clear. AI-driven battery thermal management systems can extend battery lifespan by 20–40% and improve energy efficiency by up to 25%. Advanced analytics also help reduce the risk of thermal runaway by 60–70%, ensuring that the maximum temperature difference (ΔTmax) between battery modules stays below 5°C, even under heavy stress or extreme conditions .

Telematics platforms can also analyse energy use patterns, distinguishing between driving energy, accessory energy (like HVAC systems), and regenerative braking energy. At extreme temperatures - such as –15°C - regenerative braking power can drop below 30 kW or even become negligible, reducing range by up to 21.7%. Real-time monitoring allows managers to respond immediately to thermal stresses, adjusting routes or charging speeds to prevent long-term damage.

Climate-Specific Alerts and Optimisation

Telematics systems also provide climate-specific alerts, enabling swift adjustments during extreme weather. In the UK, where weather varies significantly, adaptive thermal strategies are essential. These platforms deliver automated alerts based on seasonal and geographic conditions, prompting actions when temperatures fall below zero or rise above 30°C. This can include preconditioning batteries or adjusting routes to account for range loss .

The data highlights the impact of seasonal changes. At –15°C, energy efficiency drops by 67% in city driving and 42% on motorways, with heating systems consuming up to 51% of total energy. At 35°C, energy consumption increases by 24% in city driving, largely due to air conditioning demands. Telematics platforms can monitor the energy draw from PTC heaters and AC units separately from propulsion, helping to optimise energy use during different seasons.

For UK fleets, this capability also supports compliance with government regulations. Plug-in van and truck grants require manufacturers to demonstrate that their vehicles have effective thermal management strategies suited to UK conditions . Telematics systems ensure drivers receive real-time updates on battery status, preventing operations outside thermal specifications . Additionally, preconditioning can be scheduled remotely, allowing cabins and batteries to warm up while still plugged into chargers. This preserves driving range for actual journeys. By combining monitoring, alerts, and automated responses, telematics transforms thermal management from a reactive process into a proactive one.

Comparison of Thermal Management Methods

EV Battery Thermal Management Systems Comparison: Air vs Liquid vs PCM vs Heat Pipes

Choosing the right thermal management method depends on factors like duty cycle, budget, and how it performs in the UK's climate. Each option has its own mix of benefits, costs, and complexity, which can significantly impact fleet performance.

Air cooling is the simplest and most cost-effective option, thanks to its lightweight design and minimal maintenance requirements. However, it struggles with maintaining consistent temperatures and handling high-load conditions, making it less suitable for demanding applications. Research by Hwang et al. highlights that air-cooled systems are best suited for short-range routes, whereas liquid cooling is better for long distances and higher thermal demands.

Liquid cooling stands out for its efficiency and ability to keep temperatures within the critical 15°C to 35°C range. While it costs about 40% more than air cooling, it offers better long-term reliability by reducing the risk of thermal damage. Immersion cooling, an advanced form of liquid cooling, enhances heat transfer rates by up to 10,000 times, making it particularly valuable for fleets facing the UK's increasingly variable weather.

Phase change materials (PCM) are excellent at maintaining consistent temperatures without consuming additional energy. However, they can become saturated during extended high-load operations and add extra weight to vehicles. Heat pipes, known for their fast heat dissipation and efficiency, work well in hybrid systems but often require a secondary cooling system to handle heat dissipation. The growing preference for hybrid systems, which combine active liquid cooling with passive PCM, is seen as a reliable solution for the UK's unpredictable climate, balancing performance and durability.

The table below provides a clear comparison of these methods, highlighting their strengths, weaknesses, costs, and suitability for the UK's climate and fleet needs.

| Method | Advantages | Disadvantages | Cost Implication | UK Climate Suitability | Fleet Integration |

|---|---|---|---|---|---|

| Air Cooling | Simple, lightweight, minimal maintenance | Poor temperature uniformity, low heat capacity | Lowest cost | Moderate; suitable for urban/light use | High |

| Liquid Cooling | High efficiency, compact, handles fast charging | Complex, risk of leaks, adds weight | ~40% higher than air cooling | High; handles extreme weather well | Moderate |

| PCM (Passive) | No energy consumption, consistent temperature | Risk of heat saturation, adds weight | Moderate | Good for stable loads, less for extremes | Moderate |

| Heat Pipes | Quick response, no moving parts, high conductivity | Needs secondary system, limited heat transfer distance | Moderate | High when used in hybrid systems | Low (component-level use) |

Conclusion and Key Takeaways

Managing heat effectively is crucial for protecting your fleet and ensuring dependable performance. By keeping batteries within the ideal range of 15°C to 35°C, you can slow down degradation and extend their lifespan by 30% to 50%. This not only reduces replacement expenses but also boosts fleet availability.

Thermal management systems also deliver financial benefits. They can lower maintenance and replacement costs by about 20% while addressing the fact that batteries account for 30–50% of an EV's total cost. Over time, these systems pay for themselves by improving battery durability, cutting downtime, and reducing the likelihood of thermal runaway by 60% to 70%.

Seasonal challenges highlight the importance of these systems. In winter, preconditioning while the vehicle is plugged in helps preserve range. In summer, efficient cooling ensures faster charging and shields batteries from heat-related damage. Considering the UK's unpredictable weather, hybrid systems - blending active liquid cooling with passive phase change materials - offer a reliable solution for consistent year-round performance.

"A well-designed BTMS becomes essential for ensuring the safe and efficient operation of EVs. It acts as the guardian of the battery pack." – International Journal of Hydrogen Energy

FAQs

How does temperature impact the performance and lifespan of EV batteries?

Temperature is a key factor in how well EV batteries perform and how long they last. In colder conditions, like the typical UK winter, batteries can lose efficiency. Power output and capacity often drop noticeably because low temperatures slow down electrochemical activity. In fact, real-world range loss can be anywhere from 20% to 45%. On top of that, the extra energy needed to run heating systems in cold weather can further reduce the vehicle's range.

At the other end of the spectrum, high temperatures can speed up battery ageing, cutting down its overall lifespan. That's why thermal management systems, like cooling systems and heat pumps, are so important. These systems help regulate the battery's temperature, keeping it in the ideal range of 25°C to 35°C. This not only improves performance but also extends the battery's life and ensures dependable operation throughout the year.

As the UK moves closer to the 2030 deadline to phase out new petrol and diesel cars, taking care of EV batteries through proper temperature management is becoming increasingly crucial.

What are the best thermal management systems for EV batteries in different climates?

Picking the right thermal management system for EV batteries largely depends on your climate and what your fleet requires. Here's a closer look at two popular options:

Liquid cooling systems are a standout choice for extreme weather. These systems work by circulating coolant to actively manage battery temperatures, ensuring consistent performance whether it's freezing cold or blazing hot. This makes them a dependable solution for fleets operating in challenging, year-round conditions.

For fleets in moderate climates or those aiming to maximise energy efficiency, phase change material (PCM) systems are worth considering. These systems stabilise battery temperatures by absorbing and releasing heat as needed. Since they don't rely on moving parts, they help conserve energy while maintaining effective temperature control.

Ultimately, the decision comes down to your specific circumstances. Liquid cooling shines in harsh climates, while PCM systems suit milder environments or setups where energy efficiency is a priority.

How can telematics help fleet managers manage EV battery temperatures more effectively?

Telematics provides fleet managers with the tools to keep a close eye on EV battery health, including real-time monitoring of temperatures, charge levels, and overall condition. With this data, managers can spot when battery temperatures fall outside the optimal range of 15°C to 35°C and act swiftly to avoid issues like overheating or freezing, both of which can negatively impact battery performance and lifespan.

These systems also make it easier to plan charging cycles effectively, ensuring charging happens during cooler periods to limit thermal stress on the batteries. On top of that, telematics can regulate cooling or heating systems based on the surrounding environment, maintaining the best operating temperatures. This not only helps save energy and cut costs but also extends battery life, making it a smarter choice for the long haul.