Ultimate Guide to Construction Equipment Tracking

GPS, VHF, IoT and Bluetooth tracking to secure construction equipment, reduce theft, cut fuel and maintenance costs, and support UK compliance.

Construction equipment tracking is a must for managing assets, reducing theft, and improving efficiency on job sites. By using technologies like GPS, VHF, and IoT, companies gain real-time insights into their machinery, helping cut costs and ensure smooth operations. Key benefits include:

- Theft Prevention: Advanced systems recover 91% of stolen assets and can save businesses thousands annually.

- Cost Savings: Reduce fuel consumption by up to 15% and maintenance costs by 20%.

- Operational Efficiency: Identify underused equipment, avoid unnecessary rentals, and automate maintenance schedules.

- Compliance Support: Simplify audits and meet UK regulations like DVSA and GDPR.

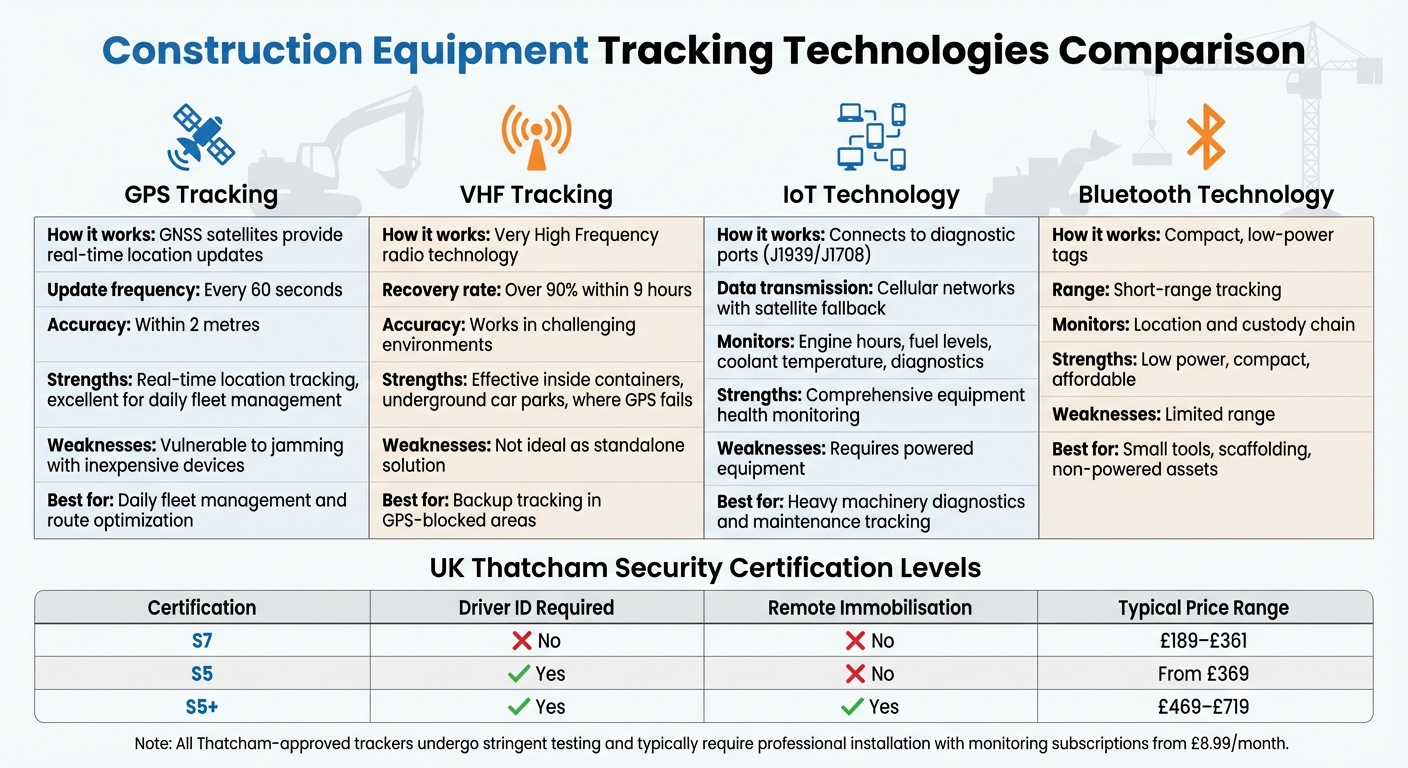

Tracking Technologies:

- GPS: Real-time location updates, but vulnerable to jamming.

- VHF: Effective in areas where GPS fails, with high recovery rates.

- IoT: Monitors engine hours, diagnostics, and fuel levels.

- Bluetooth: Ideal for smaller tools and non-powered assets.

Top Features:

- Real-time alerts and geofencing.

- Remote immobilisation for added security.

- Driver authentication to prevent unauthorised use.

- Detailed analytics for smarter decision-making.

Costs:

- Hardware starts at £35, with subscriptions from £7.99/month per vehicle.

- Insurance savings of 5–15% for using approved trackers.

GPS Tracker For Construction Equipment - Review

Technologies Used in Equipment Tracking

Construction Equipment Tracking Technologies Comparison Guide

Modern equipment tracking relies on a variety of technologies, each designed to tackle specific challenges like jamming, misplacement, and maintenance delays. Understanding these systems can help you pick the best solution for managing your fleet. Here's a closer look at how these technologies work and their key benefits.

GPS and VHF Tracking Systems

GPS tracking uses GNSS satellites to provide real-time location updates, typically every 60 seconds. With accuracy within 2 metres, it’s a vital tool for daily fleet management. However, GPS trackers are susceptible to jamming, often using inexpensive devices.

On the other hand, VHF (Very High Frequency) technology excels in environments where GPS struggles, such as inside containers or underground car parks. Research shows that VHF-enabled systems achieve over 90% recovery rates within 9 hours. For added security, dual-tracker systems combine GPS with a concealed VHF or Bluetooth backup, ensuring location data continues to transmit even if the primary tracker is compromised.

IoT and Bluetooth Technology

While GPS and VHF focus on precise location tracking, IoT and Bluetooth technologies enhance functionality, particularly for diagnostics and smaller asset management.

IoT (Internet of Things) systems go beyond location tracking by connecting to diagnostic ports (like J1939 or J1708) on heavy machinery. This allows monitoring of engine hours, fuel levels, coolant temperature, and other critical metrics. Data is transmitted via cellular networks, with satellite fallback for remote areas where mobile coverage is unreliable. As Jason Widla, Solutions Engineering Manager at Geotab, says:

"If it's powered, it's worth tracking!"

Bluetooth technology plays a different role. Compact, low-power Bluetooth tags act as backup trackers for powered equipment or as primary trackers for small tools. They’re also useful for non-powered assets like scaffolding or lighting towers, where QR codes can facilitate quick check-in and check-out processes. These tags offer a simple way to maintain a digital chain of custody.

Thatcham Security Certifications

In the UK, Thatcham Research sets the benchmark for vehicle security systems. Their certifications, particularly S5 and S7, are often required by insurers to cover high-value construction equipment against theft.

- S7 certification includes essential theft recovery features like GPS tracking, 24/7 monitoring by a Secure Operating Centre, and motion sensors that detect unauthorised movement even when the ignition is off.

- S5 certification builds on S7 by adding Automatic Driver Recognition (ADR), which requires an authorised driver ID tag for the equipment to operate.

- The top-tier S5+ certification incorporates remote immobilisation, allowing the engine to be disabled if theft is detected.

| Thatcham Category | Driver ID Required | Remote Immobilisation | Typical Price |

|---|---|---|---|

| S7 | No | No | £189–£361 |

| S5 | Yes | No | From £369 |

| S5+ | Yes | Yes | £469–£719 |

Thatcham-approved trackers undergo stringent testing to ensure they resist tampering. Many now integrate VHF alongside GPS to counter jamming attempts. These systems typically require professional installation by certified technicians and an active monitoring subscription, starting at around £8.99 per month, to maintain insurance compliance.

Key Features of Construction Equipment Tracking Systems

The most effective tracking systems bring together security, efficiency, and actionable data to safeguard assets and cut costs. They tackle challenges like theft, inefficient operations, and maintenance issues head-on.

Real-Time Monitoring and Alerts

With updates every 60 seconds, these systems provide precise geofencing alerts, saving time spent searching for equipment across multiple sites and enabling accurate scheduling of deliveries. Geofencing sets up virtual boundaries around job sites or storage yards. If a high-value machine - like a digger or dumper truck - crosses these boundaries during off-hours, you'll receive an instant SMS or email alert. Considering that an estimated 1,000 pieces of heavy equipment are stolen each month, such alerts can make the difference between recovering an excavator worth £100,000–£850,000 or losing it forever.

As GoCodes highlights:

"The cost of asset tracking or installation of a GPS system is minimal compared to the catastrophic loss of one major piece of heavy equipment."

These alerts also enable advanced security measures like remote immobilisation and driver authentication.

Immobilisation and Driver Authentication

Remote immobilisation lets you disable a vehicle’s engine through a dashboard or mobile app as soon as theft is detected. When combined with dual-tracker technology, recovery rates can reach an impressive 91%.

Driver authentication ensures that only authorised, trained personnel can operate specific machinery [3, 16]. Operators are required to use a physical ID tag or digital login before starting the engine, which helps prevent accidents due to untrained users and stops unauthorised equipment use. In the UK, plant theft costs construction businesses approximately £1 million every week.

When paired with geofencing, these systems can automatically immobilise vehicles started outside approved zones or times [3, 1]. This approach not only enhances security but also reduces accidents by 20% and fuel costs by 15%, as it discourages reckless or unauthorised driving. These features also support compliance with DVSA safety audits and the Working Time Directive.

Data Analytics and Reporting

In addition to real-time alerts and security features, robust data analytics play a key role in improving fleet performance. Usage dashboards and historical reports provide insights into engine hours and idle times, helping identify underused or unnecessarily running equipment. This allows for smarter asset allocation and reduced rental expenses [2, 5].

By automating the tracking of engine hours and diagnostic codes, these systems enable proactive maintenance, cutting unplanned repairs by up to 25%. Moving away from manual logs not only keeps warranties valid but also ensures equipment remains operational [2, 7].

Driver behaviour monitoring offers actionable insights to improve safety. Targeted coaching based on this data can reduce accident rates by up to 30%. Additionally, GPS data provides reliable evidence for resolving billing disputes and verifying project timelines [7, 16].

| Feature | Basic Tracking Systems | Advanced Systems (e.g., GRS Ultimate) |

|---|---|---|

| Location Updates | Periodic (every 3–10 minutes) | Real-time (every 60 seconds) |

| Immobilisation | No | Remote engine kill capability |

| Driver ID | No | Verification tags/authentication |

| Recovery Rate | Variable/Low | 91% |

| Theft Alerts | Basic geofencing | Instant tampering and motion alerts |

With a potential return on investment as high as 2,965%, and payback achievable in just 0.3 months, these systems combine real-time visibility with automated reporting. This gives you the tools to streamline operations, minimise waste, and protect your most valuable assets.

GRS Fleet Telematics: Tracking Solutions for Construction Equipment

GRS Fleet Telematics offers a range of tracking solutions designed specifically for construction fleets, from transit vans to heavy machinery. With features like real-time updates, geofencing, and eco-driving analytics, these tools aim to reduce theft risks and improve operational efficiency - all for a flat rate of £7.99 per vehicle per month. By focusing on the unique challenges of construction equipment management, GRS delivers tools that help businesses stay in control.

Hardware Options: Essential, Enhanced, and Ultimate Trackers

GRS provides three hardware tiers tailored to different needs:

- Essential Tracker (£35 upfront): This single hardwired unit is ideal for businesses looking for straightforward location tracking. It’s a simple yet effective solution for smaller fleets.

- Enhanced Tracker (£79 upfront): This option includes a hidden Bluetooth backup device alongside the primary wired tracker. The dual-tracker setup ensures a 91% vehicle recovery rate - even if the main tracker is disabled by thieves. This tier is ideal for operations in areas where theft is a significant concern.

- Ultimate Tracker (£99 upfront): Offering the highest level of security, this tier includes both trackers and a remote immobilisation feature. Managers can disable the engine via an app or dashboard if unauthorised movement is detected. This feature is especially useful for safeguarding plant machinery after hours. Mark Richards, Operations Manager at BuildRight Construction, shared his experience:

"Tool and van theft cost us thousands annually. Since installing GRS trackers, we've had zero thefts and recovered two attempted thefts".

All devices are Thatcham S5/S7 approved, which can help reduce insurance premiums by 5% to 20%. Compact in size (80mm × 50mm × 20mm) and rated IP67, the trackers are built to withstand water, dust, and tough site conditions.

| Feature | Essential | Enhanced | Ultimate |

|---|---|---|---|

| Upfront Cost | £35 | £79 | £99 |

| Primary Wired Tracker | Yes | Yes | Yes |

| Bluetooth Backup Tracker | No | Yes | Yes |

| Remote Immobilisation | No | No | Yes |

| Recovery Rate | Standard | 91% | 91% |

| Best For | Budget monitoring | High-theft risk protection | Maximum security & control |

Monthly Subscription Plans

For £7.99 per vehicle each month, the subscription covers SIM data, platform access, and 24/7 UK-based support. This flat-rate pricing ensures access to all software features, regardless of the hardware tier selected. These features include geofencing with instant notifications, a 365-day journey history, automated timesheet generation, and driver behaviour monitoring (e.g., speeding, harsh braking, and idling).

Geofencing allows construction firms to set virtual boundaries around job sites, triggering alerts if equipment moves without permission. It also automates site attendance logs and provides digital proof of time spent on projects, which can help resolve billing disputes with clients. Combined with the competitive subscription pricing, GRS ensures a smooth experience with comprehensive installation and support services.

Installation and Support Services

GRS offers professional installation services that take just one to two hours per vehicle. Installation is free if you opt for fleet branding via GRS Fleet Graphics; otherwise, standalone installation costs start at £145. Certified installers can come directly to your depot or job site, ensuring minimal disruption to daily operations.

During installation, the tracker is connected to the vehicle’s power system or OBDII port, discreetly placed, and tested for signal strength. Fleet managers are trained on using the dashboard, setting up alerts, and monitoring driver behaviour. Ongoing support includes 24/7 troubleshooting, regular software updates, and recovery assistance on a pay-per-recovery basis - without any upfront recovery fees.

How to Implement Equipment Tracking

Assessing Your Fleet Requirements

Start by creating a detailed inventory of your assets - everything from excavators and vans to power tools and trailers. Make sure to log essential information such as the purchase date, price, warranty details, and current condition. This step often highlights assets that might have been overlooked. Did you know that around 11% of small businesses don’t track their assets at all, and 44% still rely on manual methods like spreadsheets or paper logs?

Focus on the assets that matter most - those that are high-value or frequently on the move. For example, cranes or excavators, which can cost anywhere between £100,000 and £850,000, should be a priority. Smaller items like hand tools may not need GPS trackers. Instead, using QR code labels scanned with a smartphone app can offer a practical solution for tracking them.

What’s your main objective with tracking? If it’s security, features like geofencing and remote immobilisation are a must. If you’re aiming to improve efficiency, look for tools that provide engine diagnostics, idle time monitoring, and detailed utilisation reports. Don’t forget to check with your insurer - some may require Thatcham-approved devices to reduce your premiums.

Once you’ve identified your priorities, move on to installing and setting up your tracking systems.

Setting Up and Configuring Systems

Companies like GRS Fleet Telematics offer certified installers who can securely connect and test hardwired trackers. This ensures a tamper-resistant setup. For heavy-duty equipment, you’ll need ruggedised IP67-rated trackers that can be welded or bolted in place to handle tough site conditions.

Set up geofences around storage areas and job sites to receive instant alerts if an asset moves outside the designated zones. You can also configure maintenance reminders based on engine hours. The GRS dashboard provides additional tools, such as automated timesheet generation, driver behaviour monitoring (e.g., speeding, harsh braking, idling), and access to a full year of journey history - useful for compliance and resolving billing disputes.

Once the system is up and running, it’s essential to train your team to make the most of these tools.

Training and Monitoring

Make sure your team understands the benefits of tracking - improved safety, increased accountability, and greater efficiency. When staff realise that tracking helps protect their jobs and prevents theft, they’re more likely to support its use.

Assign a dedicated team to manage the platform and ensure they’re trained on how to use the dashboard for real-time monitoring. Implement a check-in system using QR codes or mobile apps to establish clear accountability for assets. This approach creates a transparent chain of custody and reduces the likelihood of tools being unnecessarily stored at specific sites.

You can also use telematics data to identify issues like excessive idling or aggressive driving. Address these through targeted coaching to improve fuel efficiency and lower maintenance costs . With the right training and monitoring, your tracking system becomes a powerful tool for enhancing operations and reducing expenses.

Calculating ROI from Equipment Tracking

Reducing Theft and Recovery Costs

The construction industry faces annual losses of between £230 million and £770 million due to equipment theft, with over £310 million worth of machinery stolen in the United States alone. Shockingly, less than 25% of stolen equipment is recovered without tracking systems. This means that when a single excavator, which can cost up to £850,000, is stolen, it often results in a complete financial loss.

However, tracking systems have proven to be game-changers in recovering stolen assets. For instance, GRS Fleet Telematics boasts a 91% recovery rate for stolen vehicles. In April 2025, Johnson Construction managed to recover two skid steers worth roughly £67,000 within just 24 hours of their theft. Similarly, a UK courier firm using GRS’s dual-tracker system recovered two stolen vans in a single day, preventing losses exceeding £40,000.

Beyond recovery, insurers in the UK incentivise the use of tracking systems by offering premium discounts of 5–15% for fleets with tracked assets. For a mid-sized company paying £85,000 annually in premiums, this could translate to savings of nearly £8,500 per year. Some insurers even require the use of Thatcham-approved devices to ensure coverage.

While theft prevention is a major benefit, tracking systems also deliver considerable savings in day-to-day operations.

Lowering Fuel and Maintenance Costs

Tracking systems don’t just protect assets - they also help businesses cut fuel and maintenance costs. Features like route optimisation and idle time monitoring can reduce fuel consumption by 10–20% within the first year. For a fleet spending £50,000 annually on fuel, this means savings of £5,000 to £10,000. GRS Guardian estimates that businesses save approximately £1,224.52 per month with their system, yielding an impressive 2,965% ROI.

Proactive maintenance is another area where tracking systems shine, reducing overall maintenance costs by up to 20% and unplanned repair expenses by 25%. This is especially important since reactive maintenance can be three to nine times more expensive than planned servicing. Mike Callahan, Operations Director at Westfield Construction, highlighted the impact of tracking:

"We were losing nearly $50,000 annually to theft and misplaced equipment before implementing a proper asset tracking system. Now we know exactly where every piece of equipment is and who's responsible for it".

Improving Productivity and Compliance

Equipment tracking doesn’t just save money - it also boosts productivity. Without tracking, equipment utilisation rates hover around 30–40%. By identifying underused assets, companies can unlock cash flow and avoid project delays. Johnson Construction, for example, reported a first-year net ROI of around £138,000 after implementing a tracking system.

Tracking systems also streamline operations by reducing the time spent locating equipment by 75%. Given that 82% of contractors report project delays due to missing equipment, this efficiency can be a game-changer. Additionally, automated timesheets and journey history features help resolve billing disputes and ensure compliance with DVSA regulations. In February 2025, Moove Cars saved over £3 million annually by improving fleet efficiency with telematics technology.

With costs starting at £7.99 per month per vehicle and hardware priced between £35 and £99, most companies recover their investment within six to twelve months.

Conclusion

Tracking construction equipment isn't just a smart move - it's a necessity to avoid significant financial setbacks. Losing a single high-value asset, like an excavator worth up to £850,000, can deal a serious blow to your bottom line. That's why having a reliable tracking system in place is crucial.

GRS Fleet Telematics offers real, measurable results: a 91% recovery rate, up to 15% savings on fuel, and maintenance cost reductions of up to 20%. Even better, most businesses see their investment pay off within just 6 to 12 months. But it’s not just about saving money; it’s about streamlining operations too.

Tracking systems take care of essential tasks like compliance monitoring, route planning, and proactive maintenance scheduling. These features not only cut down on admin time but also help keep your projects on track and within budget.

With hardware starting at just £35 and subscriptions from £7.99 per vehicle per month, GRS Fleet Telematics makes advanced tracking technology accessible to businesses of all sizes. The Essential tracker provides affordable, real-time monitoring, while the Enhanced and Ultimate options offer added protection with dual-trackers and remote immobilisation for high-value machinery.

Whether you're overseeing a handful of machines or managing a large fleet, equipment tracking does more than prevent theft. It boosts efficiency, cuts costs, and gives you peace of mind - helping you deliver projects on time and profitably.

FAQs

How can tracking equipment help lower fuel and maintenance costs?

Tracking construction equipment offers a practical way to cut down on fuel costs. With real-time GPS data, managers can plan more efficient routes, reduce unnecessary trips, and tackle wasteful behaviours like excessive idling or harsh acceleration. These adjustments can lead to a noticeable drop in fuel consumption - up to 15% - which translates to savings of hundreds of litres every month for UK businesses.

But it doesn’t stop there. Modern tracking systems also keep an eye on engine hours, diagnostic codes, and performance metrics. They send preventive maintenance alerts when it's time for a service, helping to avoid unexpected breakdowns. This proactive approach can lower routine maintenance expenses by about 20%. By combining smarter routing, insights into driver habits, and automated maintenance scheduling, equipment tracking not only saves money but also ensures machines stay in great working order.

What is the difference between GPS and VHF tracking systems for construction equipment?

GPS tracking systems rely on satellite technology to deliver real-time updates on location, speed, engine hours, and other key metrics. Users can access this data through a cloud-based dashboard, which unlocks features such as geofencing, route optimisation, and theft recovery alerts. These trackers are typically connected via the vehicle’s OBD-II port or a dedicated power source, and they can provide updates as frequently as every few seconds.

In contrast, VHF (Very High Frequency) tracking systems function differently. However, their application in tracking construction equipment isn't extensively documented. If you're considering VHF tracking, it's worth seeking additional information or consulting an expert to evaluate how it stacks up against GPS in terms of features and practicality.

How do tracking systems help construction companies comply with UK regulations?

Tracking systems make it easier to comply with UK regulations by automating key processes like data collection and reporting. With tools like real-time GPS and telematics software, you can maintain precise records of driver hours, vehicle maintenance schedules, and route logs - ensuring you meet standards set by the DVSA and HSE. Features like geofencing alerts add another layer of control, restricting equipment usage to authorised locations and assisting with site-access licences and environmental reporting.

These systems also simplify GDPR compliance by securely managing employee location and usage data, removing the risks associated with manual spreadsheets. Automated reminders for MOTs, emissions tests, and inspections help you avoid costly penalties by ensuring nothing is missed. Plus, with a central dashboard tracking everything from fuel consumption and driver behaviour to maintenance schedules, construction managers can streamline audits and reporting. Costs remain clear in pounds (£), with metric units used for all measurements, making it easier to stay on top of both compliance and budgeting.