Ultimate Guide to Battery Health Monitoring for Fleets

Practical guide for fleet managers to monitor EV battery health—key metrics, BMS & telematics, charging best practices, predictive maintenance and ROI.

Electric vehicle batteries can account for 30–50% of a vehicle's total cost, making their health a top priority for fleet managers. Monitoring battery health ensures fewer breakdowns, lowers maintenance costs, and extends battery lifespan. Here's what you need to know:

- Key Metrics: Track State of Charge (SoC), State of Health (SoH), temperature, and cycle count to identify issues early and optimise performance.

- Tools: Combine Battery Management Systems (BMS), telematics, and cloud analytics to monitor and analyse battery data in real time.

- Best Practices: Use AC charging, keep charge levels between 20–80%, and educate drivers on smoother driving habits.

- ROI Impact: Monitoring reduces downtime, increases resale value, and supports second-life uses for batteries.

Fleet managers can save money and improve efficiency by shifting from reactive repairs to predictive maintenance. Investing in robust monitoring systems and following these practices protects your fleet's most expensive asset - the battery.

What is a Battery Management System BMS? EV Range Prediction, Charging, Safety

Key Metrics for Battery Health Monitoring

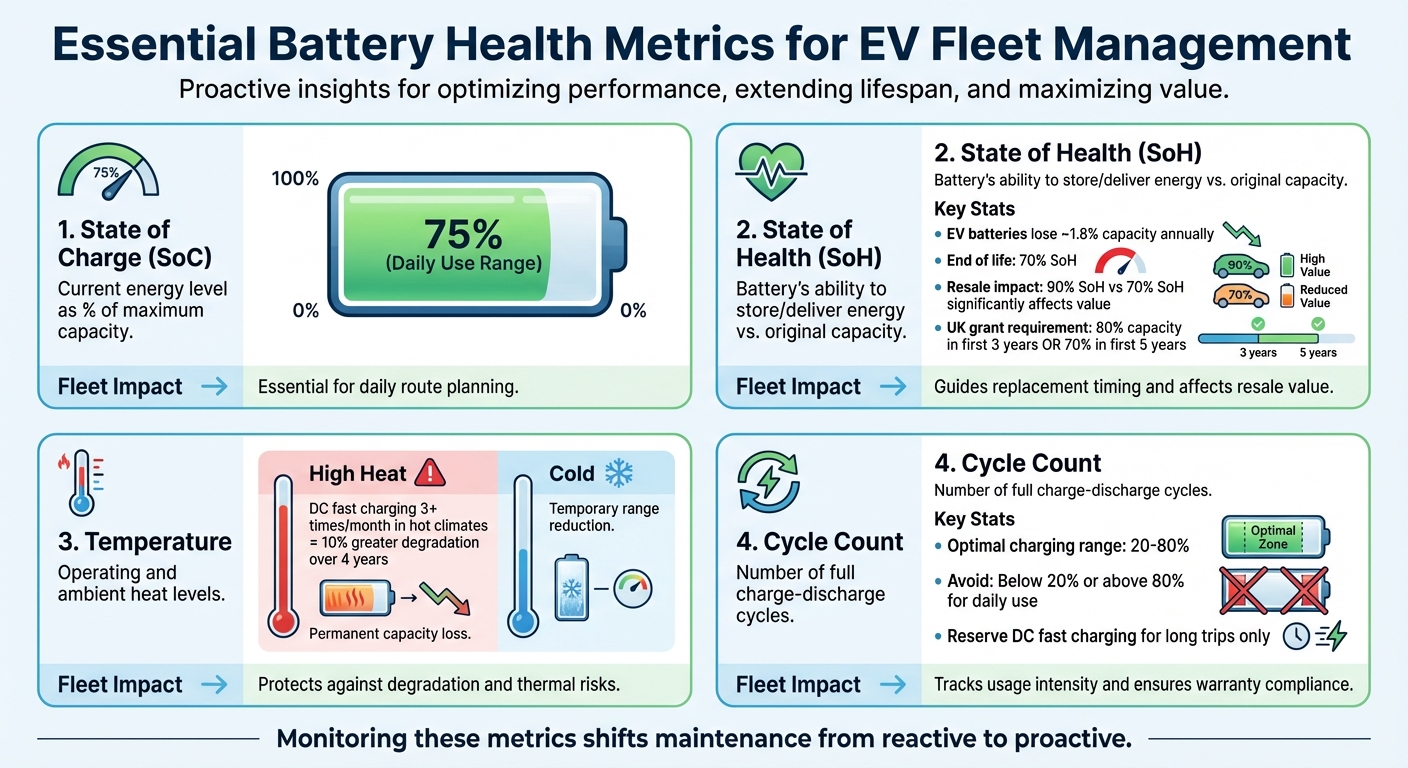

Essential Battery Health Metrics for EV Fleet Management

Keeping tabs on key battery metrics can shift maintenance from being reactive to proactive. For fleet managers, a few essential measurements can reveal both the immediate performance and the long-term condition of batteries.

State of Charge (SoC) and State of Health (SoH)

To start with, understanding the battery’s current energy status is crucial. State of Charge (SoC) works much like a fuel gauge, showing the energy level as a percentage of the battery's maximum capacity. This metric is vital for daily operations like route planning, ensuring vehicles have enough charge to complete their tasks. However, while SoC tells you where you stand right now, it doesn't offer insights into the battery's overall condition.

State of Health (SoH), on the other hand, measures the battery’s ability to store and deliver energy compared to its original capacity. As Acculon Energy explains:

"State of Health (SOH) serves as a barometer for assessing the overall health of a battery... SOH must be estimated according to external features to get insight into a battery's ability to perform as expected".

EV batteries typically lose around 1.8% of their capacity annually, and they’re often considered at the end of their usable life for vehicles when SoH drops to 70%. For fleet resale, a vehicle with a 90% SoH will fetch a much higher price than one at 70%, making this metric as important as mileage is for traditional vehicles. Additionally, UK government grants require batteries to retain at least 80% capacity in the first three years or 70% in the first five years.

Beyond capacity, temperature monitoring plays a key role in maintaining battery performance.

Temperature Management and Thermal Performance

Temperature has a direct impact on how long a battery lasts. High heat speeds up chemical degradation in lithium-ion cells, leading to permanent capacity loss. For example, vehicles using DC fast charging in hot climates more than three times a month see 10% greater battery degradation over four years compared to those that don’t. On the flip side, cold temperatures increase internal resistance, temporarily reducing range. While the long-term effects of cold are less damaging than heat, they still pose operational challenges.

The Battery Management System (BMS) uses real-time sensors to keep cells within safe temperature limits. Fleet managers can help by advising drivers to precondition vehicles while they’re plugged in and to park in shaded or covered areas during extreme weather.

After temperature, keeping an eye on cycle counts and charging habits can also provide a clearer picture of battery health.

Cycle Count and Charging Patterns

Every time a battery goes through a full charge-discharge cycle, its capacity diminishes slightly. Monitoring cycle counts helps fleet managers predict when a battery might need replacing. Certain habits - like frequent DC fast charging or letting charge drop below 20% - speed up this wear and tear. To reduce stress on the battery, it’s best to keep the charge between 20% and 80%. Fleet managers should reserve rapid charging for long trips and rely on slower Level 1 or Level 2 chargers for routine overnight charging.

Tracking metrics like cell voltage and impedance can also provide insights into how individual cells are ageing.

| Metric | What It Measures | Why It Matters for Fleet Operations |

|---|---|---|

| State of Charge (SoC) | Current energy level (%) | Helps plan daily range and routes |

| State of Health (SoH) | Remaining total capacity (%) | Guides replacement timing and affects resale value |

| Temperature | Operating and ambient heat levels | Protects against degradation and thermal risks |

| Cycle Count | Number of charge-discharge cycles | Tracks usage intensity and ensures warranty compliance |

Technologies and Tools for Battery Monitoring

Keeping an eye on battery performance involves a combination of technologies that work together seamlessly to ensure everything runs smoothly. Let’s break down these essential components.

Battery Management Systems (BMS)

Think of the Battery Management System (BMS) as the "brain" of the battery. It keeps tabs on key metrics like voltage, current, and temperature at the cell level in real time. It’s also responsible for monitoring safety parameters and running diagnostics to prevent problems such as overheating or overcharging. Another important job of the BMS is balancing the individual cells within the battery pack, making sure they all perform evenly. However, there’s a catch: the BMS itself doesn’t store data or provide long-term visibility into a battery’s condition. For that, telematics systems step in to send this critical information to the cloud, enabling deeper analysis and insights.

Telematics and IoT Integration

Telematics systems act as the bridge between the BMS and cloud-based analytics. These devices collect battery data and transmit it for further processing. Advanced telematics setups can capture data every millisecond, building a detailed history of how the battery is used. This level of detail helps fleet managers track the State of Health (SoH), assess warranty claims, and distinguish between normal wear and tear and potential misuse. Many modern platforms even integrate data from over 300 electric vehicle models, as well as traditional petrol and diesel vehicles, into a single online dashboard for streamlined management.

Cloud-Based Analytics Platforms

Once telematics systems send the data to the cloud, analytics platforms take over to turn raw information into practical insights. These platforms use the data to create "digital twins" - virtual models of each battery. With these digital twins, fleet managers can simulate different duty cycles and test calibration updates before applying them in real life. Machine learning plays a big role here, analysing data to detect early signs of trouble, such as voltage irregularities or accelerated ageing at the cell level. This predictive approach helps with timely maintenance and extends battery life. For instance, Ricardo’s Connected BMS platform has been shown to improve battery lifespan by up to 13%. Storing data in the cloud also provides a clear record for warranty claims and enables remote troubleshooting, cutting down on the need for in-person inspections.

How to Extend Battery Lifespan

Maximising the lifespan of your fleet's batteries goes beyond just keeping an eye on them - it requires deliberate actions in charging routines, driving habits, and maintenance. On average, EV batteries degrade around 1.8% each year, but with the right practices, you can keep them performing at their best for longer.

Charging Practices That Protect Your Batteries

How you charge your batteries plays a big role in how long they last. For everyday use, stick to AC charging (7kW–22kW) instead of relying heavily on DC rapid chargers. AC charging is gentler on battery cells, and overnight charging at 3.7kW for about 12 hours is usually enough to meet energy needs without putting unnecessary strain on the battery.

A good rule of thumb is the 20–80% guideline. Keep battery levels within this range for regular use and avoid charging to 100% unless you're preparing for a long journey. This buffer reduces chemical stress on the battery, which is especially important since EV batteries often need replacing when their capacity drops below 70%.

Using smart energy management tools can also help extend battery life while cutting costs. Energy Management Systems (EMS) can schedule charging during off-peak hours, helping you avoid expensive demand charges. Charging outside peak grid times (typically 6am to 11pm) can even lower greenhouse gas emissions by 10–15%. If your site has limited grid capacity, dynamic load management systems can distribute power efficiently across multiple chargers, preventing overloads and enabling more charging points without expensive upgrades.

But charging is just one part of the equation. How drivers handle the vehicles also has a big impact on battery health.

Smarter Driving for Longer Battery Life

Driving style matters - a lot. Aggressive driving, like rapid acceleration, hard braking, and high speeds, can reduce a battery's range by up to 51%. Vipul Dhingra, a Development Engineer at AVL, explains it well:

"Batteries are like human beings in that human beings age faster during stress, and batteries also age faster during stress. Heat could be a stress, high charging current could also be a stress".

Training drivers to adopt smoother driving techniques and make the most of regenerative braking can go a long way. Encourage them to avoid deep discharges (below 5%) and to charge to 100% only when absolutely necessary. Data shows that frequent rapid charging, especially in hot climates, can significantly reduce a battery's state of health (SoH).

Thermal management is equally important. Drivers should park vehicles in shaded areas or covered spaces during hot weather and precondition the cabin (cooling or heating it) while the vehicle is still plugged in. Using integrated telematics solutions, like those from GRS Fleet Telematics, can provide real-time data on energy use and battery health, helping with driver coaching and maintenance planning.

Driver education should go hand-in-hand with regular battery diagnostics to catch potential issues early.

Keeping Tabs on Battery Health

Routine diagnostics are key to maintaining your batteries. Telematics systems with cloud-based analytics can ensure continuous monitoring, but it's also important to schedule regular inspections. Most EVs display SoH data on their dashboards or through manufacturer apps like Tesla, NissanConnect, or Blue Link. Basic SoH checks every 3–6 months, combined with a more detailed annual assessment using tools like OBD2 scanners, can help identify issues like cell imbalances or thermal problems.

For more in-depth diagnostics, EV-specific OBD2 scanners - available for under £50 - can provide detailed information, including individual cell voltages, internal resistance, and temperature readings. As John Ellis, known as The EV Guy, puts it:

"The battery is the lifeline of an electric vehicle. It is the power plant that drives the propulsion of the very asset that generates revenue for your organisation".

Before key decisions like selling or returning leased vehicles, conduct a full battery health check. Keeping detailed SoH records is essential, especially since warranties often require proof that capacity has fallen below 60–70% to be valid. Regular monitoring not only helps prevent unexpected issues but also protects the residual value of your vehicles.

ROI and Long-Term Benefits of Battery Monitoring

Battery monitoring plays a crucial role in protecting your financial investment. Since the battery can account for 30–50% of the total cost of an electric vehicle (EV), monitoring transforms what might seem like a liability into a valuable asset. This proactive approach brings tangible benefits, including reduced maintenance costs and longer asset lifespans.

Reducing Downtime and Maintenance Costs

Real-time monitoring enables predictive maintenance, identifying potential issues before they lead to downtime. By tracking key metrics like temperature, voltage, and current, fleet managers can catch early warning signs and schedule repairs during off-peak times, minimising disruptions and avoiding unexpected costs. If problems arise, telematics systems allow for cell-level diagnostics, meaning only the faulty cells need replacing rather than the entire battery pack.

Additionally, cloud-based data storage supports warranty claims by distinguishing between normal wear and manufacturing defects. Since most EV warranties only cover battery replacement when the State of Health (SoH) falls below 60–70%, maintaining detailed records ensures you can make claims before warranties expire.

Extending Battery Lifespan and Supporting Sustainability

Preserving battery health directly impacts the value of your assets. With effective monitoring and maintenance, EVs can save fleet operators two to three times the operating costs of internal combustion engine (ICE) vehicles. Preventing accelerated battery degradation is key - research shows that using DC fast charging more than three times a month in hot climates can lead to a 10% higher degradation rate over a 48-month period compared to batteries that avoid frequent fast charging.

A longer battery lifespan doesn’t just save money; it also aligns with sustainability objectives. When batteries reach around 70% SoH - the typical threshold for automotive use - they can be repurposed for energy storage in homes or industrial settings. This second-life application generates additional revenue while reducing waste. Such practices align with emerging EU and UK regulations on battery passports and lifecycle traceability, promoting a more circular economy. Together, these gains enhance both operational efficiency and sustainability.

Better Decision-Making with Data Insights

Access to real-time and historical data on charging habits, temperature, and driving behaviours empowers fleet managers to make smarter decisions. Monitoring uncovers patterns that influence long-term battery performance. As Team ChargePoint explains:

"By implementing predictive maintenance practices and analysing battery performance trends, early warning signs of potential failures can be identified and addressed promptly".

This data-driven approach can also boost resale value. For example, a used EV with 90% SoH is far more appealing - and valuable - than a similar model with 70% SoH. For fleets preparing for vehicle disposal or lease returns, documented battery health provides concrete evidence to maximise remarketing returns.

Integrated telematics platforms bring it all together, combining data from battery management systems, charging stations, and vehicle sensors into a single dashboard. This unified view supports strategic decision-making and simplifies fleet management.

For fleet managers in the UK, advanced telematics solutions - like those offered by GRS Fleet Telematics - can further enhance battery monitoring efforts. These tools seamlessly integrate into existing fleet strategies, helping to achieve both cost efficiencies and environmental goals.

Conclusion

As we've explored, keeping a close eye on battery health is a must for fleet operators managing electric vehicles. By using advanced monitoring tools, you can protect your investment, cut down on maintenance expenses, and extend the lifespan of your batteries - all while keeping your fleet running smoothly.

Predictive maintenance plays a big role in spotting potential issues early, preventing costly repairs down the line. Meanwhile, detailed diagnostics at the cell level can help significantly lower repair costs. Keeping thorough records of battery health can also boost resale values when it's time to replace vehicles. In short, smart battery management is the foundation for reaping these benefits and avoiding early battery wear.

Switching from reactive to proactive fleet management starts with better visibility. Real-time insights into factors like temperature, voltage, charging habits, and State of Health give you the tools to make smarter decisions. Whether it’s improving your charging infrastructure or educating drivers on battery-friendly habits, these insights are invaluable. After all, the battery is the heart of your revenue-generating vehicles, making monitoring a critical part of your operational strategy.

For fleet managers in the UK looking to tap into these benefits, advanced telematics solutions are the key. Providers like GRS Fleet Telematics offer integrated systems that enhance battery monitoring and align seamlessly with your management goals. These tools help you achieve not only operational efficiency but also progress towards sustainability targets.

Managing electric fleets requires a fresh approach to asset management. By adopting an integrated strategy, you can shift towards proactive fleet management while balancing day-to-day operations with long-term sustainability. Start prioritising battery health monitoring now to reduce costs, maximise uptime, and ensure the longevity of your electric fleet.

FAQs

How does monitoring battery health affect the resale value of fleet vehicles?

Monitoring the health of a vehicle's battery is essential for preserving, and even enhancing, the resale value of fleet vehicles. By keeping an eye on metrics like battery capacity, voltage, and temperature, fleet managers can spot early signs of wear and address them promptly. This not only keeps the battery in good working order but also helps extend the overall lifespan of the vehicle.

When it comes to resale, having detailed battery health records can make all the difference. Clear evidence of proper maintenance can reassure buyers and may even lead to a better selling price. Advanced tools like telematics systems play a key role here, offering accurate tracking of battery performance and ensuring warranty conditions are met. This kind of proactive management not only protects the vehicle's value but also helps avoid expensive, early battery replacements.

How does temperature affect the lifespan of vehicle batteries?

Temperature is a major factor influencing how long vehicle batteries last. When exposed to high temperatures, the chemical reactions inside the battery accelerate, which can drastically shorten its lifespan. For instance, just a 10°C rise in operating temperature can cut the battery's life in half.

In contrast, colder conditions temporarily lower the battery's capacity but can actually help prolong its lifespan in the long run. Keeping batteries within an ideal temperature range is essential for ensuring they perform well and remain reliable over time, especially for fleet operations.

How does telematics improve battery health monitoring for fleets?

Telematics plays a crucial role in keeping tabs on battery health by offering real-time data on temperature, voltage, current, and state of charge (SOC). This continuous flow of information helps fleet managers spot early warning signs of battery wear or potential problems. Acting on these insights promptly means you can tackle issues before they escalate, which not only prevents unexpected breakdowns but also extends the battery's lifespan and keeps vehicles running smoothly.

Another advantage of telematics is its ability to fine-tune charging schedules based on the battery's condition. By avoiding excessive fast charging - a common culprit behind premature battery degradation - fleet operators can maintain healthier batteries. These systems ensure safer, more dependable operations, cutting down on both downtime and maintenance costs. The result? A more efficient fleet with reduced disruptions and better long-term performance.