Telematics for Construction: Remote Diagnostics Explained

Telematics remote diagnostics monitor machine health in real time to cut downtime, reduce fuel waste and enable predictive maintenance for construction fleets.

Remote diagnostics is transforming construction fleet management. It uses telematics to monitor equipment health in real time, reducing breakdowns, saving costs, and improving efficiency. By tracking engine hours, fault codes, and fuel consumption, managers can plan maintenance based on actual machine conditions instead of fixed schedules.

Key Takeaways:

- What It Does: Tracks equipment health remotely using sensors and real-time data.

- How It Works: Sensors detect issues (e.g., engine faults, hydraulic failures) and send alerts via 4G/5G or satellite to cloud systems for analysis.

- Benefits: Cuts downtime by up to 20%, saves fuel (up to 30% during idle time), and supports predictive maintenance.

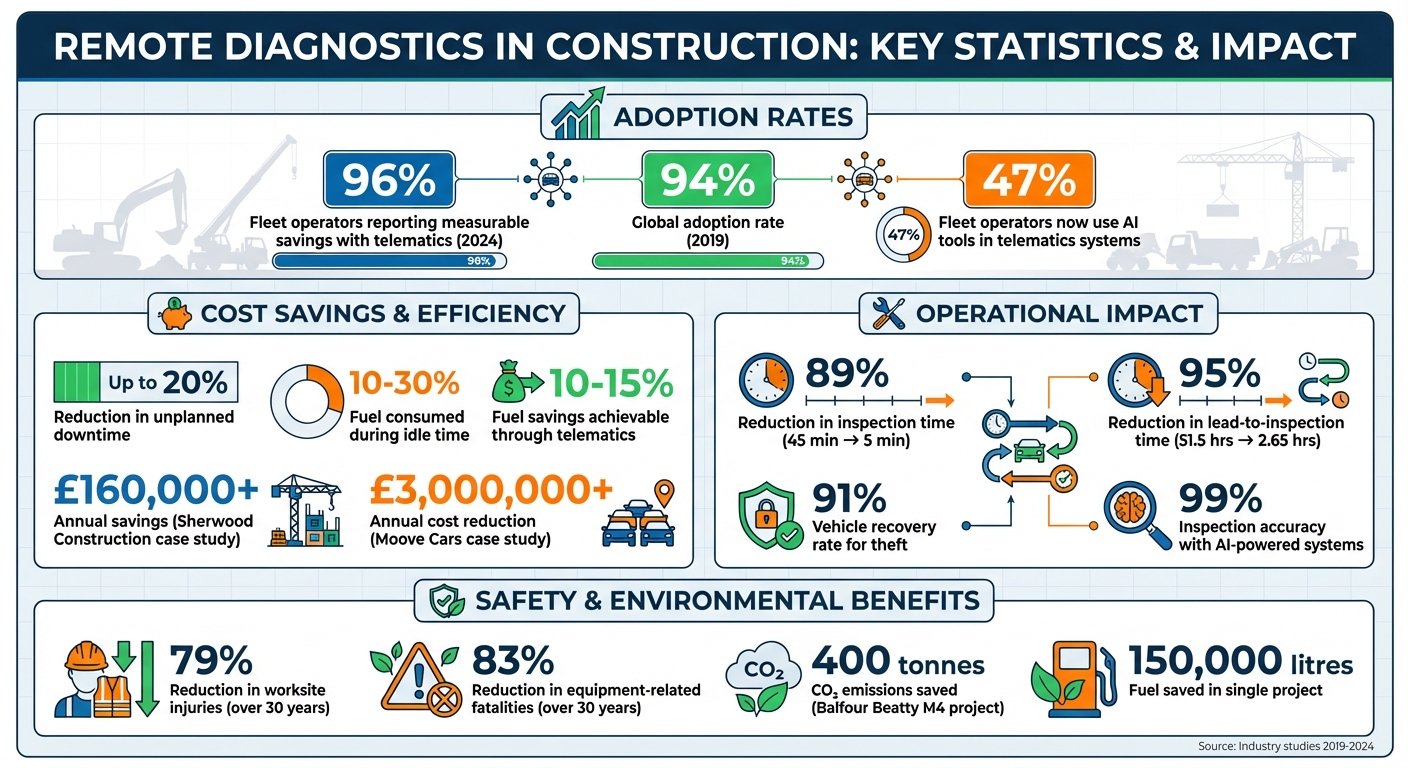

- Adoption Trends: 96% of fleet operators report savings with telematics, and AI integration is increasing for smarter diagnostics.

- Challenges: Connectivity issues in remote areas, GDPR compliance, and data management.

Remote diagnostics is no longer optional for businesses aiming to improve fleet efficiency, reduce costs, and meet stricter regulations. Whether you're managing a mixed-brand fleet or using factory-installed systems, this technology ensures better oversight and smarter decision-making.

Remote Diagnostics ROI: Key Statistics for Construction Fleet Management

Digitizing Equipment Management: Dieci's Success with Telematics | Industry 4.0 Transformation

What Is Remote Diagnostics in Construction?

Remote diagnostics is a telematics tool designed to keep tabs on the health and performance of construction equipment. Instead of relying on manual checks or waiting for operators to spot issues, this system uses sensors and communication technologies to detect problems as they happen. It identifies Diagnostic Trouble Codes (DTCs) in real time, flagging faults like engine troubles or hydraulic system failures the moment they arise.

This approach moves away from traditional maintenance methods, which often follow fixed schedules - like servicing equipment every 500 hours - or react only after a breakdown disrupts operations. With remote diagnostics, you get a "real-time pulse" on your machinery, enabling maintenance based on the actual condition of the equipment rather than relying on guesswork.

As Mike Granruth, Director of Business Development at Trimble, puts it: "Things have evolved from knowing where a piece of equipment is, to knowing what that piece of equipment is doing."

The system doesn't just improve fault detection; it also ensures more reliable data. Traditional methods often involve manual data logging, which can lead to mistakes or incomplete information. By automating data collection directly from the machine's engine interface, remote diagnostics tracks critical metrics - like engine hours, idle time, and hydraulic pressure spikes - accurately, rather than depending on less relevant measures such as odometer readings.

How the Technology Works

At the core of remote diagnostics is the Telematics Control Unit (TCU), which is installed in each piece of equipment. The TCU includes microcontrollers, memory, and sensor ports to continuously collect performance data. It connects to the machine's internal systems through wired interfaces like the CAN bus or Automotive Ethernet, pulling data directly from the engine and onboard sensors.

The sensors monitor key parameters such as engine load, oil pressure, coolant temperature, fuel consumption, and battery levels. If something abnormal - like overheating or unusual vibrations - is detected, the system generates a DTC to pinpoint the issue. This information is then sent via 4G LTE, 5G, or satellite to secure cloud servers. From there, advanced analytics software processes the raw data into visual dashboards and automated reports. Managers can use these tools to run remote diagnostic tests, review fault codes, and even send software updates to equipment on distant job sites.

Tak Sunagawa, Managing Director and CEO of JRC Mobility Germany GmbH, explains: "Through real-time monitoring of machine health, preventative maintenance can be carried out, reducing the need for unscheduled maintenance or repairs."

Uses in Construction Equipment

The benefits of this technology are clear. One of its most immediate applications is fault code detection. If a hydraulic hose bursts or a brake system shows signs of wear, the system notifies managers instantly, helping to prevent breakdowns that could delay a project.

Another key use is monitoring hydraulic systems. For example, by tracking pressure spikes in hydraulic lines, managers can predict when a hose is likely to fail. If data shows a hose typically fails after three significant pressure spikes, they can replace it after the second spike, avoiding unexpected downtime.

Remote diagnostics also helps cut fuel waste by monitoring idle time. Construction equipment can burn through 10% to 30% of its fuel while idling unnecessarily. By identifying which machines or operators are responsible for this inefficiency, managers can take targeted action. During the M4 smart motorway upgrade project in April 2022, Balfour Beatty used telematics to tackle excessive engine idling, saving 150,000 litres of fuel and reducing CO₂ emissions by 400 tonnes.

Adoption Rates and Current Trends

The benefits of remote diagnostics are becoming increasingly evident, and the construction industry is taking notice. What was once seen as optional technology is now becoming a necessity. For instance, telematics adoption in the UK jumped from 38% in 2015 to 66% in 2016, with global adoption reaching an impressive 94% by 2019.

Fast forward to 2024, and 96% of fleet operators using telematics report measurable savings - whether through better fuel efficiency, streamlined administrative tasks, or reduced operational costs. Nick Walker, Managing Director at RAC Telematics, highlights that telematics now provides not only cost savings but also deeper operational insights and improved duty of care.

The evolution of telematics technology is equally noteworthy. Today, 47% of fleet operators are incorporating AI tools into their systems to automate complex tasks and simplify data analysis. This marks a shift from basic GPS tracking to advanced capabilities like vehicle health monitoring, predictive maintenance, and real-time diagnostics - all aimed at minimising downtime before it even occurs.

Industry Adoption Patterns

The way telematics is implemented is also changing. OEM factory-installed systems - such as Caterpillar VisionLink, JCB LiveLink, and JLG ClearSky - are increasingly standard features, offering remote diagnostics from the moment equipment leaves the factory. This eliminates the need for aftermarket installations, streamlining the process for fleet managers.

Meanwhile, third-party integration platforms are becoming essential for managing mixed fleets. Tools like InTempo and Point of Rental allow companies to consolidate data from multiple manufacturers into a single, unified dashboard. This approach simplifies fleet management and enhances operational efficiency.

Integration with Enterprise Resource Planning (ERP) and Computerised Maintenance Management Systems (CMMS) is accelerating as well. These connections enable automated processes like generating work orders and updating hour meters in real time, reducing manual input and improving data accuracy. A case in point: in April 2025, Tarmac, a construction materials company, implemented a combined telematics solution from Motormax and Geotab. This initiative aimed to create a safer, more sustainable, and data-driven fleet by leveraging real-time data to enhance safety and reduce environmental impact [Source: Geotab Success Stories, 2025].

The AEMP 2.0 (ISO 15143-3) data standard is also playing a pivotal role. By allowing fleet managers to aggregate data from mixed-brand fleets into a single platform, this standard eliminates the need for manual reconciliation, making data management more efficient.

Regulatory and Regional Factors

Regulations like the UK’s Stage V emissions standards are driving the adoption of more sophisticated engine monitoring systems. These systems not only meet regulatory requirements but also support remote diagnostics by tracking critical parameters like DPF cycles and SCR fluid levels.

At the same time, GDPR compliance remains a key consideration. When telematics systems monitor operator behaviour or location data, construction firms must balance operational benefits with privacy obligations. To address this, many companies are focusing on machine-level diagnostics rather than tracking individual operators, ensuring they capture essential performance data without raising privacy concerns.

Data-sharing standards, such as AEMP 2.0, are gaining importance as both regulatory bodies and clients demand more transparency around carbon emissions and equipment usage. However, adoption is still limited - only 18% of UK construction respondents currently share data on life cycle emissions through digital tools, though this is a slight increase from 2021’s 16%.

Roger Esson, Head of Sales at Centurion UK Rentals & Services, emphasises: "Digitalisation in the built environment is no longer optional - it is essential for driving efficiency and sustainability for our clients".

Insurance providers are also shaping adoption trends. Many now offer discounts to firms that use telematics for safety monitoring and theft recovery. For smaller contractors, who may have previously considered telematics too expensive, these financial incentives can make a big difference. Recovering just one or two mid-sized machines can often cover the cost of an entire telematics programme.

These trends are setting the stage for a deeper exploration of the benefits and return on investment that remote diagnostics can offer.

Benefits and ROI of Remote Diagnostics

Cost and Performance Benefits

Remote diagnostics bring undeniable financial perks. For example, 96% of fleet operators using telematics report savings through streamlined administration, better fuel efficiency, and lower operational costs.

One of the standout benefits is the reduction in unplanned downtime - up to 20% according to studies. As Ted Polzer, Director of Product and Customer Support for North America at Case Construction, puts it:

"You can never eliminate downtime because maintenance still needs to happen. But telematics helps an equipment manager pick a good time to schedule it when the downtime will be least impactful".

Fuel efficiency is another area where telematics shines. Idle fuel consumption can account for 10% to 30% of total usage, but telematics can cut this by 10% to 15%. For example, one large fleet saved 6,000 gallons of diesel weekly, translating to around £25,000 per week or £650,000 annually. This also reduced CO₂ emissions by a staggering 134,630 pounds. Even small changes can add up - cutting idle time by just 20 hours a year can save between £2,000 and £3,000 per large-frame crawler excavator.

AI-powered remote inspections are revolutionising efficiency, slashing inspection times from 45 minutes to just 5 minutes - an 89% reduction in labour time. Managed Business Services, for instance, reduced lead-to-inspection time by 95%, dropping from 51.5 hours to just 2.65 hours.

The benefits extend beyond cost savings. Construction firms using van tracking have achieved a 91% recovery rate for stolen vehicles. Insurance providers are taking note, offering lower premiums for fleets equipped with telematics. Telematics also helps reconstruct accidents, reducing fraudulent claims and further cutting insurance costs.

Remote diagnostics enable predictive maintenance by monitoring factors like hydraulic pressure spikes and fuel use patterns. This approach avoids rigid schedules and prevents both catastrophic failures and unnecessary part replacements. It’s worth noting that the purchase price of heavy machinery often represents less than 10% of its total life-cycle cost, with fuel, maintenance, and repairs accounting for up to five times the initial cost. Dave Adams, Product Sales Manager at Volvo Construction Equipment, highlights the impact of idle time:

"The difference of 2,500 lifetime hours can cut thousands from the resale value... all because of increased idle time".

By optimising equipment use, businesses can shorten ROI payback periods from 18 months to just 12 months. Sherwood Construction, for example, saved over £160,000 per year by integrating mixed fleet telematics. Similarly, Moove Cars cut costs by more than £3,000,000 annually through Geotab telematics technology.

These examples highlight how remote diagnostics can deliver substantial operational and financial rewards, even as they come with certain challenges to navigate.

Advantages and Disadvantages

While the benefits are clear, remote diagnostics also introduce hurdles that businesses must address.

| Category | Advantages | Disadvantages / Challenges |

|---|---|---|

| Maintenance | Predictive alerts reduce major failures and extend equipment lifespan. | Requires upfront investment in hardware and software integration. |

| Operations | Cuts downtime by 20%. | Low driver engagement due to privacy concerns. |

| Costs | Fuel savings (up to 25% per mile) and lower insurance premiums. | Ongoing subscription costs. |

| Data/Security | 91% theft recovery rate and 99% inspection accuracy. | Data privacy concerns and GDPR compliance requirements. |

| Connectivity | Real-time visibility across multiple jobsites. | Connectivity issues in remote or underground locations. |

One significant challenge is connectivity. Remote diagnostics depend on stable internet or satellite coverage, which can be inconsistent at remote jobsites or underground construction sites. This can delay data transmission, limiting the effectiveness of real-time monitoring.

Another pressing issue is data privacy, particularly under GDPR regulations. When telematics systems track operator behaviour or location, companies must balance operational needs with privacy obligations. Many firms focus on machine-level diagnostics to avoid tracking individuals directly.

Data overload is also a concern. Without proper system integration and training, managers may struggle to interpret the sheer volume of information collected. Giles Bolton, Sales Director at Grosvenor, stresses the importance of streamlined tools:

"The stats highlight how our ARC SMR tool is helping fleet managers dramatically reduce vehicle downtime by delivering a more proactive approach to SMR. Cost and time savings associated with optimal vehicle health is priceless".

Despite these challenges, the evidence suggests that the benefits of remote diagnostics far outweigh the drawbacks for most construction operations. With phased rollouts, driver engagement initiatives, and effective system integration, these obstacles can be successfully managed.

What's Next for Remote Diagnostics

The construction industry is quickly embracing autonomous operations and machine-to-machine communication. By the end of 2024, 5G networks reached around half of the global population. This expanded connectivity is setting the stage for real-time, fully autonomous diagnostics.

Jeff Drake, Business Area Manager for Machine Control Systems at Trimble, captures this shift:

"The next step will be when you have communication between machines... When the machines themselves can start to talk to each other and ask questions. Am I working too close to something? Should I stop the machine? Should I call another machine over to finish this?"

Interoperability is becoming the norm in the industry. A notable example is Komatsu's "My Komatsu" digital hub, launched in March 2022. This platform allows customers to access telematics data from multiple brands using ISO 15143-3 API credentials. This standard supports the sharing of about 30 key data points across manufacturers, simplifying the management of mixed equipment fleets. Matthew Beinlich, Director of Digital Support Solutions at Komatsu, explains:

"Now, our customers can get the most important telematics data, such as location, hours, fuel consumption, idle ratio and production, from My Komatsu for many of the other brands of equipment they may operate."

The integration of AI and IoT is expected to further revolutionise machine operations. Future systems will be able to analyse driving behaviour and engine loads to optimise routes and reduce fuel consumption. Tak Sunagawa, Managing Director and CEO of JRC Mobility Germany GmbH, highlights this trend:

"In order to save manpower, we will see a greater need for the autonomous operation of construction equipment. AI and IoT will also be an increasingly important part of the telematics solution."

Another key development is the move towards predictive maintenance. On-board sensors will soon predict potential failures, eliminating the need for fixed service schedules. With the speed of 5G networks, these systems will enable rapid remote diagnostics, offering a level of precision that was previously unattainable.

Construction firms are also adapting by creating specialised digital roles to make sense of telematics data. With nearly half of all new heavy construction machines now equipped with factory-installed telematics systems, the focus is shifting from simply installing hardware to extracting actionable insights that enhance efficiency and performance.

Conclusion

Remote diagnostics and telematics have reshaped the way fleets are managed, offering a shift from reactive problem-solving to proactive maintenance strategies. With access to real-time equipment data - like engine hours, fault codes, and hydraulic pressure - managers can plan maintenance during low-impact times, avoiding costly breakdowns and disruptions.

This proactive approach doesn't just streamline operations; it also delivers measurable financial benefits. Take Sherwood Construction, for example: by addressing inefficiencies through unified telematics data, they saved over £130,000 annually. Similarly, BuildRight Construction eliminated losses from van theft entirely by implementing advanced tracking systems. Mark Richards, Operations Manager at BuildRight Construction, highlighted the impact:

"The best van tracker UK construction firms can invest in - it's paid for itself many times over in prevented losses and improved efficiency".

Dual-tracker systems further bolster security, achieving a 91% recovery rate for stolen vehicles. Features like geofencing and instant alerts for unauthorised movement, combined with remote immobilisation, have become indispensable for safeguarding high-value construction assets. These systems not only enhance security but also contribute to better safety and efficiency.

Telematics’ benefits extend beyond cost savings. The technology has played a key role in improving safety and environmental compliance. Over the past 30 years, it has helped reduce worksite injuries by 79% and cut equipment-related fatalities by 83%. Additionally, fuel monitoring tools aid firms in meeting climate-related disclosure requirements while keeping operating costs in check.

FAQs

How does remote diagnostics enhance equipment maintenance in construction?

Remote diagnostics uses telematics sensors and on-board systems to deliver real-time updates on the condition of construction machinery like excavators and loaders. By tracking critical metrics such as engine temperature, oil pressure, fuel usage, and vibration levels, it becomes possible to detect potential problems early - without requiring engineers to be physically present.

This method comes with some clear advantages. Predictive maintenance allows parts to be replaced before they fail, avoiding expensive breakdowns and keeping projects running smoothly. Continuous monitoring also reduces the need for unnecessary inspections and helps cut idle fuel usage, saving on diesel costs (measured in £ per litre in the UK) while lowering emissions. On top of that, it enhances safety by identifying faults that could lead to accidents. GRS Fleet Telematics offers these features in one platform, giving UK construction companies an efficient way to handle diagnostics, plan maintenance, and keep detailed records of equipment health.

What challenges do construction sites in remote areas face when using telematics?

Using telematics on remote construction sites comes with its fair share of challenges, particularly connectivity issues. Many rural or isolated areas simply don't have reliable cellular or broadband networks. This often results in patchy signals or delayed data uploads, which can interfere with key functions like location tracking, engine diagnostics, and real-time alerts. When the data flow is disrupted, the overall effectiveness of the system takes a hit.

Another hurdle is the harsh conditions typically found in these remote environments. Extreme weather, dust, moisture, and constant vibrations can take a toll on telematics devices, leading to malfunctions or inaccurate readings. To make matters worse, the lack of on-site technical support means that repairs or replacements can be both time-consuming and expensive.

GRS Fleet Telematics tackles these problems head-on with their durable, dual-tracker technology. Designed to ensure consistent data capture even in areas with weak signal strength, their system offers a reliable solution. Plus, with prices starting at just £7.99 per month, it’s a cost-effective option for UK contractors working in remote and challenging locations.

How does AI improve telematics for construction fleets?

AI is revolutionising telematics by turning raw data from construction vehicles and equipment into useful, actionable insights. By leveraging machine learning, it can predict when components might wear out or fail, allowing for remote diagnostics that significantly cut down on expensive downtime. It also examines factors like fuel consumption, engine load, and operating hours to suggest the best refuelling stops, route changes, or load adjustments. These insights not only help reduce fuel usage but also extend the lifespan of equipment.

On-site, AI is making workplaces safer and more efficient. It can identify unsafe driving habits, detect unusual vibrations, and spot other anomalies in real time. Paired with advanced connectivity, AI can even analyse video feeds to flag hazards, ensure compliance with site rules, and automatically generate detailed reports. For contractors in the UK, this translates to smoother operations, reduced costs, and improved adherence to health and safety standards.

The GRS Fleet Telematics platform incorporates these AI-powered features, offering tools like remote diagnostics alerts, fuel-saving recommendations, and safety insights. Starting at just £7.99 per month, it provides construction companies across the UK with the means to keep equipment running longer, boost productivity, and protect their financial performance.