How Remote Diagnostics Reduce Fleet Downtime

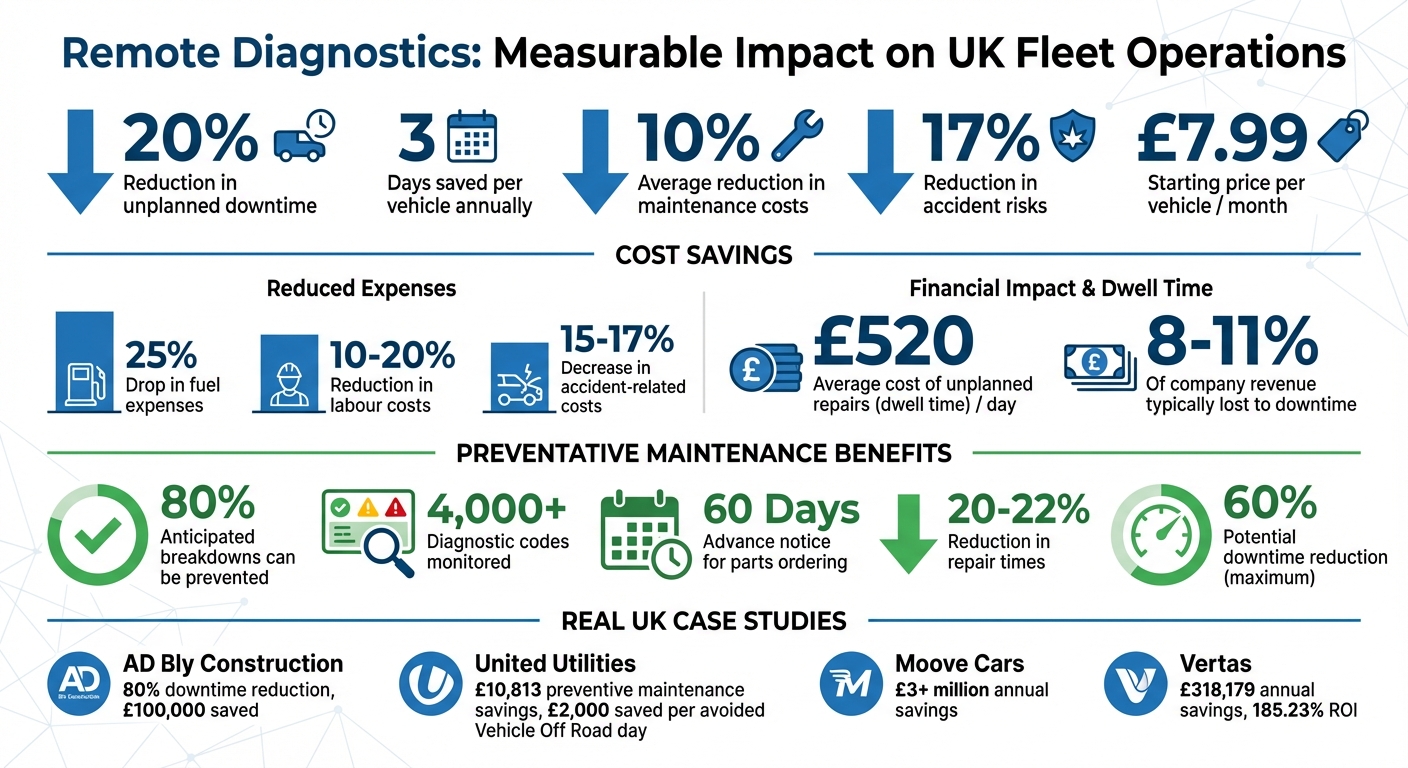

Real-time remote diagnostics using telematics, IoT and AI can reduce unplanned fleet downtime up to 20%, lower maintenance costs and speed repairs.

Remote diagnostics is helping UK fleet operators cut vehicle downtime by up to 20%. By using IoT sensors, telematics, and cloud-based analytics, this technology tracks vehicle health in real time, identifying issues before they become costly breakdowns. Key benefits include:

- Reduced unplanned downtime: Saves up to 3 days of downtime per vehicle annually.

- Lower maintenance costs: Early fault detection prevents expensive repairs, cutting costs by an average of 10%.

- Improved efficiency: Real-time alerts ensure maintenance is scheduled based on actual vehicle condition, not fixed intervals.

- Enhanced safety: Continuous monitoring identifies critical faults early, reducing accident risks by up to 17%.

With affordable solutions starting at £7.99/month per vehicle, remote diagnostics is accessible for fleets of all sizes. Combined with advancements like 5G connectivity and AI-driven analysis, this technology is reshaping fleet management by keeping vehicles on the road longer and operating more efficiently.

Remote Diagnostics Impact on UK Fleet Operations: Key Statistics and Cost Savings

Smarter Fleet Management with MyDINO | Trackunit Customer Success Stories

How Remote Diagnostics Reduces Fleet Downtime

Remote diagnostics continuously pulls data from the CAN (Controller Area Network) to keep an eye on thousands of DTCs (Diagnostic Trouble Codes) across engines, transmissions, brakes, and other vehicle systems. This uninterrupted data flow allows fleet managers to spot potential problems early - before they turn into expensive breakdowns.

The system uses a colour-coded alert mechanism - Green for healthy systems, Yellow for minor issues that can wait until the next scheduled service, and Red for critical problems needing immediate attention. This approach avoids overwhelming managers with unnecessary alerts while ensuring urgent faults are prioritised.

Advanced predictive analytics add another layer of efficiency. For example, they can detect anomalies - like sudden spikes in NOx sensor temperatures - before dashboard warnings even appear. In many cases, over-the-air updates can resolve these issues in minutes, drastically cutting repair times compared to traditional methods.

Predictive Alerts for Preventative Maintenance

Predictive alerts take maintenance to the next level by replacing fixed schedules with servicing based on the vehicle's actual health data. This proactive approach is highly effective, potentially preventing up to 80% of anticipated breakdowns.

Take Speedy Services UK as an example. Gareth Jones, their Group Fleet Compliance Manager, rolled out Ford Telematics Essentials across a fleet of 1,000 vehicles, including 200 Ford vans. The system’s ability to monitor over 4,000 diagnostic codes allowed his team to detect early signs of trouble and schedule maintenance before minor issues escalated. Jones remarked:

"Avoiding vehicle downtime is critical for our business and Ford Telematics Essentials allows us to identify any issues and take action before they become serious."

This proactive strategy not only boosts fleet productivity but also streamlines workshop visits. By sharing real-time diagnostic data with dealerships, parts can be pre-ordered, and technicians can prepare in advance, reducing repair times by 20% to 22%. The result? Vehicles spend less time in the shop and more time on the road.

Real-Time Monitoring of Engines and Systems

Beyond predictive alerts, real-time monitoring keeps tabs on critical components like engine performance, transmission health, brake systems, emissions controls (including DPF soot levels and EGR coolers), battery voltage, and tyre pressure. Research shows that around 10% of a fleet’s vehicles will have a serious fault requiring immediate attention, underscoring the need for continuous monitoring.

This level of oversight gives fleet managers a detailed understanding of each vehicle's condition, enabling faster and more confident maintenance decisions. For instance, when critical systems show signs of wear - like brakes nearing dangerous levels or a drop in cooling system pressure - managers receive instant alerts. This allows them to act promptly, preventing breakdowns before they happen.

Dave Covington, Chief Technology Officer at Noregon Systems, highlights another advantage of remote diagnostics:

"Remote diagnostics represents a much needed solution to the shortage of qualified technicians. If a top-level technician can remotely diagnose fleet vehicles, that frees up the rest of the staff to perform repairs when the vehicles arrive to the shop."

Measurable Benefits: Cost Savings and Efficiency Gains

Lower Operating Costs

Remote diagnostics significantly reduce expenses by shifting fleet maintenance from reactive fixes to proactive, data-driven schedules. Businesses in the UK adopting telematics have reported an average 10% reduction in maintenance costs and a 25% drop in fuel expenses. These savings are achieved by catching minor faults early, preventing them from escalating into costly emergency repairs that often require expedited parts.

For example, in February 2025, Moove Cars announced annual savings exceeding £3 million after streamlining its fleet operations. Additionally, labour costs can be trimmed by 10% to 20% through more efficient maintenance processes and automated scheduling. Downtime, which typically accounts for 8% to 11% of a company's revenue, can also be significantly reduced.

Accident-related costs see a notable decline too, dropping by 15% to 17%. This is thanks to continuous monitoring, which identifies risky driving behaviours and mechanical issues before they lead to collisions. One UK construction firm managing over 100 vehicles achieved an impressive 75% reduction in at-fault accidents by using telematics to enhance driver behaviour.

Beyond cost savings, remote diagnostics play a crucial role in keeping fleets operational and minimising downtime.

Better Fleet Uptime Performance

The effect on vehicle availability is just as impactful. In June 2025, a major fleet operator introduced an advanced remote connectivity tool that reduced unplanned downtime by 20% and saved three days of technical downtime per vehicle annually. A sales director highlighted the tool's benefits:

"The stats highlight how our ARC SMR tool is helping fleet managers dramatically reduce vehicle downtime by delivering a more proactive approach to SMR. Cost and time savings associated with optimal vehicle health is priceless."

Another system has shown the potential to cut downtime by up to 60%. This is achieved by monitoring over 4,000 diagnostic codes, allowing technicians to diagnose issues and order parts up to 60 days before a scheduled workshop visit. Proactive measures like these can prevent approximately 80% of expected breakdowns, ensuring vehicles spend more time on the road and less in the shop.

Case Studies: UK Fleet Applications

Results from UK Fleet Operators

Fleet operators across the UK have seen measurable improvements in efficiency and cost savings thanks to remote diagnostics. These real-world examples highlight the benefits across different industries, from construction to utilities.

AD Bly Construction, a groundworks firm based in Knebworth, revamped its 180-vehicle fleet management process. Fleet Manager Adam Gamlin replaced outdated manual systems - like spreadsheets and paper files - with FleetCheck software and TomTom vehicle tracking. This upgrade to automated, real-time monitoring slashed downtime by 80% and saved the company approximately £100,000. Gamlin shared:

"Since introducing the system, accidents have become less frequent across the fleet... Overall, I estimate downtime has been reduced by 80%."

United Utilities, which operates over 2,300 vehicles for water and wastewater services, adopted Vodafone Business Fleet Analytics powered by Geotab between January 2022 and July 2023. By using engine management light alerts and servicing based on engine hours instead of mileage, they achieved preventive maintenance savings of £10,813. The shift to proactive maintenance also helps prevent costly breakdowns - one past truck engine failure cost £60,000 and caused 23 days of downtime. Now, avoiding just one Vehicle Off Road day saves the business an average of £2,000, factoring in expenses like vehicle hire and driver overtime, while significantly reducing overall fleet downtime.

GRS Fleet Telematics and Remote Diagnostics

Features That Support Remote Diagnostics

GRS Fleet’s telematics system takes vehicle tracking to the next level with its dual-tracker setup. It combines a primary hardwired tracker with a hidden Bluetooth backup, ensuring uninterrupted tracking even if tampering occurs. This setup has contributed to an impressive 91% recovery rate for stolen vehicles. The system provides location updates every 60 seconds via Google Maps, offering pinpoint accuracy within two metres.

By connecting directly to the vehicle’s ECM, the system keeps tabs on diagnostic trouble codes (DTCs), engine hours, and fuel usage. Automated service alerts based on real-time odometer readings or engine hours help schedule maintenance before issues arise. The geofencing feature allows users to set virtual boundaries, sending instant alerts if a vehicle strays outside approved zones or operates beyond designated hours.

The Ultimate tier includes remote immobilisation, which allows the engine to be disabled in the event of theft. This feature proved invaluable for a UK courier in 2024, enabling the recovery of two stolen vans within 24 hours and preventing losses exceeding £40,000. Additionally, the platform aligns with GDPR compliance and DVSA safety regulations by automating driver hours recording and issuing maintenance reminders.

Pricing for UK Businesses

GRS Fleet offers flexible pricing options tailored to businesses in the UK, with three hardware choices to suit different needs. The Essential package (£35) provides single-unit real-time tracking, while the Enhanced package (£79) adds a Bluetooth backup for extra security. For £99, the Ultimate package includes all features, including remote immobilisation. Installation fees are waived for businesses that use GRS Fleet Graphics for vehicle branding.

With no long-term contracts, the system is ideal for fleets of any size. Studies show that the Guardian tracking system can save businesses £14,694.25 per vehicle annually, delivering a return on investment of 2,965% and achieving payback in just 0.3 months.

This all-encompassing solution not only strengthens vehicle security but also reduces downtime through proactive maintenance and rapid theft recovery. It’s a smart investment for businesses looking to optimise their fleet operations.

Future Developments in Remote Diagnostics

Remote diagnostics are set to reshape how UK fleets manage vehicle health. One of the key drivers of this transformation is 5G connectivity, which enables ultra-fast communication between vehicles and diagnostic systems. This technology allows critical metrics - like engine temperature, vibration, and pressure - to be streamed in real time. A striking example of this progress came in September 2022, when Volvo Trucks' Monitoring Centre in Ghent demonstrated how far diagnostics have come. They reduced the time needed for a full diagnostic check on tens of thousands of trucks to just eight minutes. Compare that to 2016, when checking a fleet of a few hundred trucks took an entire day. As Matthias Tytgat, Manager at Volvo Trucks' Monitoring Centre, put it:

In 2016, we were remotely monitoring just one component and it took us a full day to complete a full check in a fleet of several hundred trucks. Today, we're monitoring multiple components in tens of thousands of trucks, and we can complete a full check of the whole fleet in just eight minutes

5G isn’t the only game-changer. Artificial intelligence (AI) is pushing diagnostics beyond reactive fixes to predictive and even prescriptive maintenance. AI systems analyse vast amounts of data - factoring in variables like weather and transport conditions - to predict and prevent potential faults. To give you an idea of the scale, heavy-duty trucks generate about 20 GB of data every minute, covering over 600,000 metrics. AI can identify patterns that would otherwise go unnoticed, with around 77% of alerts successfully preventing unplanned breakdowns. Robert Valton, Head of Data, Analytics & AI at Volvo Group, highlighted this leap forward:

With AI, we can conduct even more of the analysis onboard the truck itself... It would almost be like a cognitive and self-healing truck

Cloud-based analytics platforms are also evolving, helping to sift through the enormous volumes of data and distil them into actionable insights. These platforms combine vehicle diagnostics with external factors to create highly accurate predictive models. They can even automate tasks like scheduling maintenance and ordering parts, reducing repair times significantly. For example, in early 2023, UK-based facilities management company Vertas adopted Trakm8 telematics across its fleet of 298 commercial vehicles. This initiative, led by Head of Fleet Lee Howes, delivered annual savings of £318,179 and achieved a return on investment of 185.23%. These cloud-powered tools complement the connectivity and predictive capabilities already in use.

The evolution doesn’t stop there. "Smart trailers" equipped with 5G sensors are now monitoring ABS, tyre inflation, cargo conditions, and even door security. Over-the-air (OTA) updates are another advancement, allowing remote software fixes for electronic issues, eliminating the need for workshop visits. For UK fleet managers, the challenge lies in ensuring their current hardware is compatible with these technologies and training staff to interpret and act on the data effectively. Together, these developments promise to further reduce fleet downtime and streamline operations.

Conclusion

Remote diagnostics are transforming fleet maintenance in the UK, shifting the focus from reactive repairs to proactive monitoring. This approach can reduce unplanned downtime by as much as 20%, saving fleets roughly three days of downtime per vehicle annually. In some cases, reductions have reached an impressive 60%. Considering that unplanned repairs can cost around £520 per day in dwell time, these savings translate into a substantial financial advantage.

The benefits aren't just theoretical - real-world examples from UK fleet operators highlight the tangible impact of these systems. Businesses have reported multi-million-pound savings and significant reductions in critical downtime by adopting remote diagnostics.

GRS Fleet Telematics builds on these successes with an integrated, cost-effective platform starting at just £7.99 per vehicle per month. Their system offers a combination of theft prevention - boasting a 91% recovery rate - real-time tracking, and diagnostic monitoring. This is further enhanced by dual-tracker technology and round-the-clock recovery support.

Looking ahead, advancements in 5G connectivity, AI-driven maintenance tools, and cloud-based analytics promise to push downtime reductions even further. Fleet operators who embrace these technologies today will not only see immediate cost and efficiency gains but will also be well-positioned to benefit from future innovations. The real question isn’t whether to adopt remote diagnostics - it’s how soon you can get started.

FAQs

How can remote diagnostics minimise fleet downtime and prevent costly breakdowns?

Remote diagnostics keep a constant eye on vehicle performance, capturing fault codes as they happen. This means fleet managers can spot potential problems early and schedule maintenance before minor issues turn into costly repairs.

Taking care of faults ahead of time helps businesses dodge unexpected breakdowns, hefty towing fees, and extended periods of vehicle downtime. The result? Smoother operations, lower repair bills, and a boost in fleet productivity.

How does AI improve remote diagnostics in fleet management?

AI is transforming remote diagnostics by leveraging machine learning to analyse live vehicle data and spot potential problems before they escalate into serious breakdowns. By recognising fault patterns and predicting when components might fail, it supports preventative maintenance, keeping fleets running smoothly and efficiently.

For fleet operators, this means tackling issues early, cutting down on expensive repairs, and extending the lifespan of vehicles. With sharper insights and quicker responses, AI-powered diagnostics are reshaping fleet management, making it more dependable and streamlined.

How can fleet operators ensure their vehicles work with the latest remote diagnostics technology?

Fleet operators aiming to stay ahead with remote diagnostics need to start by equipping their vehicles with the right on-board hardware. Most modern vans and trucks already come with a CAN-bus or OBD-II port, which provides essential diagnostic data. To make the most of this, a telematics device is crucial. This device should not only read signals but also securely transmit them via a cellular connection. Opting for hardware with features like GPS, engine interface modules, accelerometers, and a SIM slot ensures a well-rounded solution.

Keeping the telematics device up to date is just as critical. Regular firmware updates enable the system to decode the latest fault codes and support new over-the-air functionalities. Additionally, operators should ensure strong 4G or 5G network coverage along their routes. Encrypted data transmission is another must-have to safeguard sensitive information and maintain seamless communication.

For enhanced reliability, systems like GRS Fleet Telematics provide dual-tracker technology, ensuring data flow even in tough conditions. By combining durable hardware, consistent updates, and secure connectivity, fleet operators can keep their vehicles fully compatible with remote diagnostics. This approach not only reduces downtime but also boosts overall productivity.