Predictive Maintenance for EV Fleets: ROI Explained

Telematics-driven predictive maintenance reduces EV downtime and maintenance costs, extends battery life and delivers rapid payback with high ROI.

Predictive maintenance is transforming how EV fleets are managed, offering a data-driven way to prevent breakdowns and cut costs. By using real-time data from IoT sensors and AI, fleet managers can anticipate issues like battery degradation before they become expensive problems. This proactive approach improves reliability, reduces downtime, and lowers maintenance expenses.

Here’s why it matters:

- Cost Savings: Predictive maintenance reduces maintenance costs by up to 36% and unplanned downtime by 2.5× compared to reactive strategies. EVs already cost less to maintain than petrol or diesel vehicles, with an average service, maintenance, and repair (SMR) spend of £221 by year three, compared to £401 for ICE vehicles.

- Battery Health: Monitoring battery metrics like cell voltage and charging performance extends battery life and improves resale value. Simple practices like pre-conditioning vehicles and off-peak charging further reduce wear and costs.

- Efficiency Gains: Fleets can see up to 30% improvements in energy efficiency and fewer workshop visits, boosting vehicle availability and productivity.

Telematics systems power predictive maintenance by tracking key data, such as battery health and driver behaviour. With tools like real-time alerts and eco-driving analytics, managers can reduce downtime, improve safety, and save money. On average, predictive maintenance offers a 520% ROI, with payback achieved in under a year.

For UK businesses, solutions like GRS Fleet Telematics make implementing predictive maintenance affordable, starting at £7.99 per vehicle per month. By combining cost savings, improved reliability, and extended asset lifespan, predictive maintenance is a smart investment for EV fleet operators.

Cost Savings and ROI Metrics for Predictive Maintenance

Maintenance Cost Reductions

Predictive maintenance can significantly lower maintenance expenses - by as much as 36%. This is achieved by identifying and addressing minor faults before they escalate into costly repairs. With real-time diagnostic tools, technicians can step in early, preventing small issues from snowballing into major problems.

Unscheduled emergency repairs often lead to extended downtime, adding to operational costs. A striking example is Zipcar's AI-driven scheduling, which slashed vehicle downtime by 71% in Washington, D.C., in 2025. For fleet managers, especially those overseeing tight schedules and service contracts, such improvements can make a world of difference.

The cost benefits are even clearer when comparing electric vehicles (EVs) to traditional internal combustion engine (ICE) vehicles. Data from the 1link Service Network, which manages around 409,560 EVs, shows that by the end of year three, EVs cost an average of £221 in service, maintenance, and repair (SMR) expenses, compared to £401 for petrol and diesel vehicles - a nearly 45% saving. Tim Meadows, Chief Commercial Officer at epyx, highlighted this trend:

"Essentially, what we are seeing is both noticeably lower running costs and numbers of garage visits for EVs compared to both hybrids and ICE vehicles. By the end of year three, these are quite substantial – the EV SMR spend is not much more than half seen for ICE."

| Metric (at Year 3) | Electric (EV) | Hybrid | ICE (Petrol/Diesel) |

|---|---|---|---|

| Average SMR Spend | £221 | £341 | £401 |

| Average Garage Visits | 1.36 | 1.53 | 1.53 |

(Source: epyx 1link Service Network Data)

In addition to lower repair costs, advanced battery monitoring enhances fleet value by prolonging battery life and improving resale potential.

Battery Lifespan and Resale Value Benefits

For EV fleets, battery health is a cornerstone of value retention. Real-time monitoring of battery cell voltage helps detect and resolve issues early, extending the battery's lifespan and preserving the vehicle's overall worth. This proactive approach prevents costly replacements while maintaining long-term fleet performance.

Driver habits also play a pivotal role. Training drivers to pre-condition vehicles - heating or cooling the cabin while the vehicle remains plugged into a charger - reduces battery strain and minimises discharge cycles, thereby extending battery life. Coupled with optimised charging schedules during off-peak hours, these measures not only protect the battery but also cut operational costs.

Efficiency Improvements

Predictive maintenance doesn't just save money - it also boosts operational efficiency. By leveraging data-driven strategies, fleets can achieve up to 30% improvements in energy efficiency. This translates to lower electricity bills and more miles per charge. Additionally, fewer unplanned repairs mean vehicles spend less time in workshops, increasing fleet availability and revenue potential.

A 2022 Geotab study of 46,000 European fleet vehicles revealed that 59% could be replaced by EVs with a lower Total Cost of Ownership (TCO). Electrifying these vehicles would save fleets a combined £218 million over seven years. On average, this equates to savings of £7,960 per vehicle over its seven-year lifespan. These numbers underscore how predictive maintenance enhances the economic case for EV adoption, making it an even smarter investment for fleet managers.

Predictive Maintenance in EV Fleet with Telematics Control Unit

Predictive vs Reactive Maintenance: A Comparison

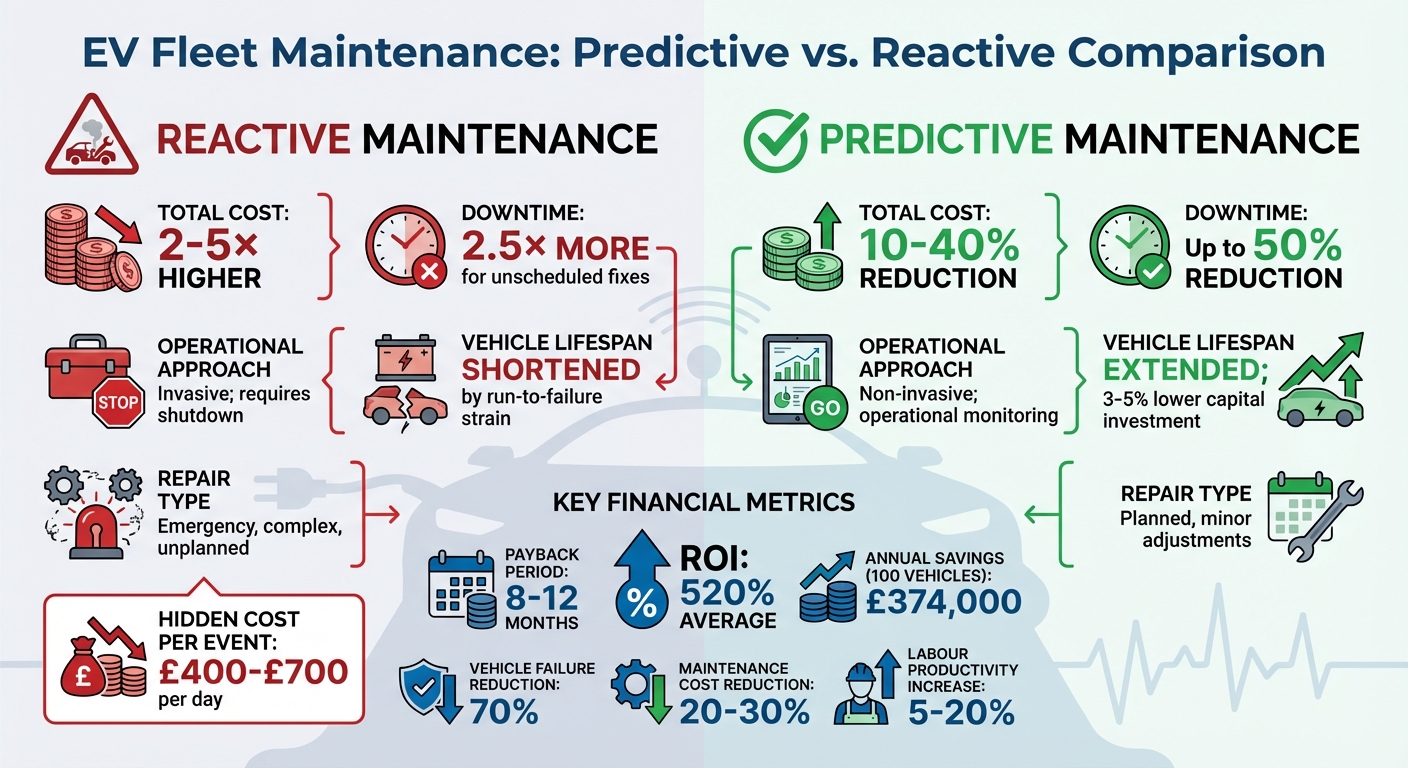

Predictive vs Reactive Maintenance: Cost and Downtime Comparison for EV Fleets

Total Cost of Ownership: Predictive vs Reactive

Unscheduled repairs lead to 2.5 times more downtime compared to planned maintenance tasks. The Marshall Institute puts it plainly: "You'll pay 2-5 times as much as you would have if you'd performed proactive maintenance". On the other hand, predictive maintenance offers measurable advantages, including a 10% to 40% reduction in maintenance costs and up to 50% less vehicle downtime. For electric vehicle (EV) fleets, the benefits go even further. Predictive strategies can extend the lifespan of vehicles, reducing equipment and capital costs by 3% to 5%.

These figures make the financial case for adopting a proactive maintenance strategy.

| Metric | Reactive Maintenance | Predictive Maintenance |

|---|---|---|

| Total Cost | 2–5× higher | 10–40% reduction |

| Downtime | 2.5× more for unscheduled fixes | Up to 50% reduction |

| Operational Approach | Invasive; requires shutdown | Non-invasive; operational monitoring |

| Vehicle Lifespan | Shortened by run-to-failure strain | Extended; 3–5% lower capital investment |

| Repair Type | Emergency, complex, unplanned | Planned, minor adjustments |

The Hidden Costs of Reactive Maintenance

While the numbers clearly favour predictive maintenance, the hidden costs of reactive approaches often go unnoticed. For instance, each unscheduled maintenance event can cost anywhere from £400 to £700 per day.

Reactive maintenance tends to focus on addressing symptoms rather than resolving the root causes of issues. Jaime Maqueda Alonso, Senior Marketing Specialist at Geotab, explains the impact of this approach:

"The result is costly, service-impacting repairs, longer downtime due to their unplanned nature, and higher expenses from the greater severity of the faults."

Predictive maintenance shifts the focus entirely. By leveraging real-time diagnostic tools and monitoring metrics like battery cell voltage, fleet managers can catch small problems before they escalate into major safety risks. As DwyerOmega points out, "Predictive maintenance is non-invasive, meaning" operations can continue uninterrupted while conditions are monitored directly. This method not only lowers costs but also boosts labour productivity by 5–20% and reduces facility downtime by 5–15%.

How Telematics Enables Predictive Maintenance

Telematics systems make predictive maintenance possible by collecting real-time data on key factors like battery health, vehicle diagnostics, and driver behaviour. Through sensors and communication networks, these systems relay critical information - such as state of charge (SoC), battery cell voltage, and Diagnostic Trouble Codes (DTCs) - to centralised cloud platforms. Fleet managers can then keep a close eye on vehicle conditions, spotting potential issues before they snowball into expensive breakdowns.

This constant flow of data is what shifts maintenance from reactive to predictive. Jaime Maqueda Alonso, Senior Marketing Specialist at Geotab, puts it this way:

"By moving from preventative to predictive maintenance, engineering teams gain the ability to act before faults escalate into breakdowns."

Some systems even take it a step further, calculating "true range" and assessing battery strain while factoring in external elements like terrain, traffic, and weather. This continuous monitoring feeds into advanced analytics for both battery performance and driver behaviour.

Battery Health Monitoring and Alerts

Battery packs are the priciest part of an EV, even with the sharp decline in lithium-ion costs. Real-time monitoring of battery cell voltage allows quick detection of irregularities, prompting early action to avoid critical failures. Any significant voltage deviations trigger immediate alerts, ensuring swift intervention.

Tracking charging rates and energy use also helps maintain battery health. Fleet managers can identify early signs of battery wear, like slower charging or reduced range, and adjust operations accordingly. This data-driven approach not only keeps vehicles charged for their daily schedules but also pinpoints the best "off-peak" charging times to save on electricity costs.

A great example of this is Revel, a rideshare company based in New York. By combining telematics with AI-driven smart charging, Revel achieved real-time insights into both vehicle and charger performance. This led to cost reductions of up to 45%, all while keeping their electric fleet running smoothly.

Eco-Driving Analytics and Fleet Optimisation

Telematics doesn’t stop at battery monitoring - it also improves fleet efficiency by influencing driver behaviour. Eco-driving analytics track habits like harsh braking, excessive idling, and aggressive acceleration, all of which drain energy and wear out components faster. Real-time feedback helps drivers adjust, cutting energy costs and extending the lifespan of vehicles.

Take G4S, a global security firm, as an example. They installed on-board computers and driver displays in their HGV and LCV fleet, tracking both engine health and driving patterns. The results? A 43% drop in idle time, a 66% improvement in driver safety scores, and a yearly reduction of two tonnes of CO2 emissions. These changes not only lowered maintenance expenses but also boosted operational efficiency.

Fleet optimisation also includes pre-conditioning, where vehicles are heated or cooled while still plugged into the charger. This conserves battery power for driving instead of using it for climate control during trips. Telematics systems can automate pre-conditioning based on departure schedules, ensuring vehicles start each journey with maximum range.

GRS Fleet Telematics: EV Fleet Solutions

GRS Fleet Telematics takes these advantages further by offering integrated solutions tailored for UK businesses. Their platform supports predictive maintenance strategies with real-time tracking and monitoring tools that cover vehicle health, battery performance, and driver behaviour. With dual-tracker technology and a 91% recovery rate for stolen vehicles, they deliver both operational efficiency and asset protection.

The system’s eco-driving analytics feature helps fleet managers identify drivers who might need additional training while recognising those who operate vehicles efficiently. This not only cuts energy costs but also reduces wear and tear, directly improving return on investment. Real-time alerts ensure maintenance issues are addressed during planned downtime, avoiding the chaos of emergency repairs.

At £7.99 per vehicle monthly, the subscription includes SIM/data, dedicated account management, and full platform access. Hardware options range from the Essential tracker (£35) for basic tracking to the Ultimate package (£99), which includes immobilisation for added security. To make the transition easier, GRS also offers free installation when paired with their fleet branding services, minimising upfront costs for businesses adopting predictive maintenance strategies.

Conclusion: Maximising ROI with Predictive Maintenance

Predictive maintenance for EV fleets isn't just a smart strategy - it’s a proven financial win. On average, it delivers an impressive 520% ROI, with payback achieved within 8–12 months. For a fleet of 100 vehicles, this translates to approximately £374,000 in annual savings by slashing breakdowns, improving battery health, and cutting energy costs.

By adopting predictive maintenance, vehicle failures can be reduced by 70%, and maintenance expenses drop by 20–30%. Unscheduled repairs, which cause 2.5 times more downtime than planned servicing, become far less common. This means fewer emergency call-outs and less reliance on expensive replacement vehicles.

The benefits don’t stop there. Enhanced battery performance management plays a key role in these savings. Across European EV fleets, the average saving reaches £7,960 per vehicle over seven years, thanks to reduced energy and maintenance costs. Using telematics to monitor battery voltage and charging habits helps prevent early degradation and ensures charging happens during off-peak hours.

With solutions like GRS Fleet Telematics, these advantages become even more accessible. Their system combines real-time tracking, battery health monitoring, and eco-driving analytics for just £7.99 per vehicle per month. Hardware starts at £35, and free installation is offered when paired with fleet branding services. This makes the initial investment manageable while delivering substantial long-term returns.

Incorporating telematics-driven predictive maintenance revolutionises fleet operations. It minimises downtime, extends the lifespan of assets, and significantly reduces costs - making it one of the smartest investments for businesses managing EV fleets.

FAQs

How does predictive maintenance help extend the lifespan of EV batteries?

Predictive maintenance plays a key role in keeping EV batteries in good shape by monitoring their performance and spotting potential problems early. By focusing on factors like charging habits and exposure to extreme temperatures, fleet operators can take steps to slow down battery wear and tear.

For instance, keeping the battery charge within the 20% to 80% range and avoiding excessive fast charging can help reduce strain on the battery. On top of that, advanced telematics systems can detect subtle changes in performance early on. This allows operators to adjust charging routines and minimise the chances of premature battery failure. The result? Longer-lasting batteries, fewer replacement costs, and a more efficient fleet overall.

What are the financial advantages of using predictive maintenance for EV fleets?

Predictive maintenance for electric vehicle (EV) fleets can be a game-changer when it comes to managing costs and keeping operations running smoothly. By cutting down on unexpected repairs and minimising vehicle downtime, it offers a smart way to save money. After all, unplanned maintenance can be as much as 2.5 times more expensive than routine servicing.

Taking a proactive approach helps businesses spot potential problems early. This not only keeps fleets running at their best but also extends the lifespan of vehicles and reduces overall maintenance costs. The result? A more efficient operation with fewer disruptions to your fleet's daily activities.

How do telematics systems support predictive maintenance for EV fleets?

Telematics systems play a crucial role in keeping electric vehicle (EV) fleets running smoothly through predictive maintenance. By collecting real-time data from onboard sensors, these systems keep an eye on key factors like battery health, energy consumption, charging habits, and overall vehicle performance. This continuous monitoring allows fleet managers to detect potential problems early, avoiding expensive breakdowns and minimising downtime.

With the help of advanced analytics and machine learning, telematics can forecast when maintenance is needed, fine-tune charging schedules, and help extend the lifespan of vehicles. For EV fleets, where battery performance and reliability are at the heart of operations, telematics systems ensure vehicles stay efficient and ready for the road. By improving reliability and cutting overall operating costs, predictive maintenance powered by telematics has become an essential part of managing modern fleets effectively.