Lifecycle Impact of UK Fleet Operations

Compare lifecycle emissions and costs for UK fleets — EVs, diesel, hybrids and alternative fuels — and how telematics reduces emissions and TCO.

Fleet operations in the UK have a much broader impact than just emissions from exhaust pipes. A Lifecycle Assessment (LCA) examines the environmental footprint of vehicles across their entire lifecycle: production, use, and disposal. Key findings include:

- Electric vehicles (EVs) have low emissions during use but high production impacts, especially from battery manufacturing.

- Diesel vehicles produce most emissions during use, while hybrids fall in between.

- Alternative fuels like biomethane can cut emissions by up to 80%, but others, like natural gas, may increase emissions.

Telematics systems help reduce emissions by improving driving habits, optimising routes, and enabling predictive maintenance. These tools also lower costs and improve fleet efficiency by reducing downtime and fuel use. For fleet managers, a lifecycle approach is vital to balancing cost, compliance, and emission reduction goals.

The Importance of LCA in Evaluating the Environmental Performance of Future Electric Vehicles

Key Findings from UK Lifecycle Assessment Studies

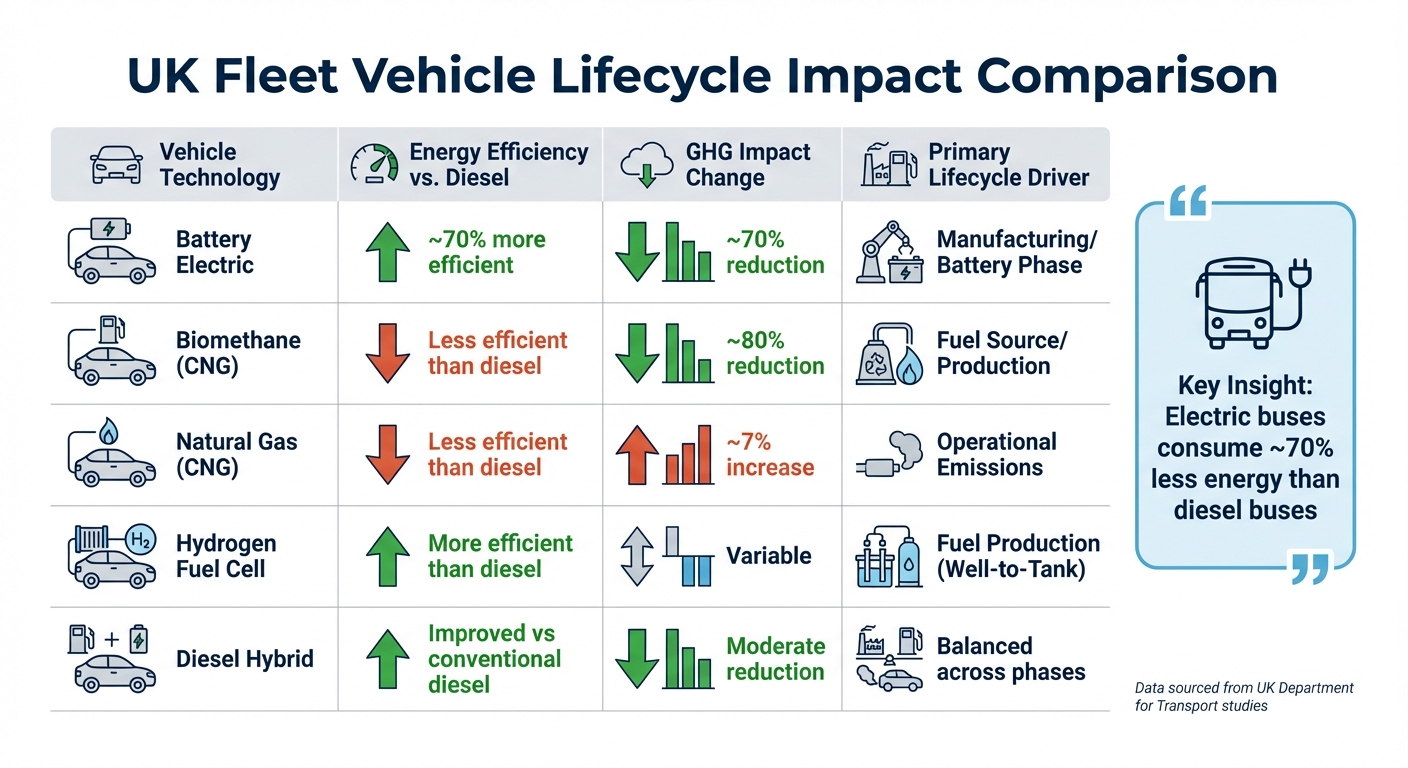

UK Fleet Vehicle Lifecycle Comparison: Energy Efficiency and Emissions by Technology

Diesel, Hybrid, and Electric Fleet Impacts

A study by Ricardo Energy & Environment, commissioned by the Department for Transport, examined 65 different vehicle and powertrain combinations across seven categories. The findings reveal how the choice of powertrain significantly alters lifecycle impacts.

For diesel and traditional internal combustion engine (ICE) vehicles, the majority of greenhouse gas emissions occur during the operational phase, often referred to as 'Tank-to-Wheel' emissions. In contrast, electric vehicles shift much of their environmental impact to the production phase, particularly during battery manufacturing. However, they balance this out with significantly lower emissions during use.

To provide a complete picture, the study also evaluated up to 14 electricity chains and 60 fuel chains. This detailed approach underscores the complexities of UK fleet operations, where the carbon intensity of the electricity used to charge electric vehicles can vary widely.

These findings set the groundwork for a more direct comparison of technologies across different fleet types.

Fleet Technology Comparison

Understanding the lifecycle impacts of various powertrains is essential, especially when factoring in lifecycle costs and fleet management systems.

Electric buses, for example, consume around 70% less energy and achieve similar reductions in greenhouse gas emissions compared to diesel buses. The performance of alternative fuels varies more. Compressed natural gas (CNG) buses running on standard natural gas can produce up to 7% more greenhouse gas emissions than diesel. However, when powered by biomethane, these vehicles can reduce emissions by 80%.

| Vehicle Technology | Energy Efficiency vs. Diesel | GHG Impact Change | Primary Lifecycle Driver |

|---|---|---|---|

| Battery Electric | ~70% more efficient | ~70% reduction | Manufacturing/Battery Phase |

| Biomethane (CNG) | Less efficient than diesel | ~80% reduction | Fuel Source/Production |

| Natural Gas (CNG) | Less efficient than diesel | ~7% increase | Operational Emissions |

| Hydrogen Fuel Cell | More efficient than diesel | Variable | Fuel Production (Well-to-Tank) |

(Data sourced from)

Hydrogen fuel cell buses, while more efficient than diesel, generally fall short of the performance seen in battery-electric models. Diesel hybrid buses, on the other hand, provide a middle ground. They offer improved efficiency and reduced emissions compared to conventional diesel vehicles, without the high manufacturing impact associated with fully electric vehicles.

Hybrid Vehicle Cost and Emissions Savings

Hybrid vehicles combine the advantages of internal combustion engines and electric powertrains, but this dual setup also introduces added mechanical complexity. Tim Meadows, Chief Commercial Officer at Epyx, remarked:

Vehicles with ICE and EV capabilities add complexity, requiring more workshop attention.

Beyond emissions, lifecycle costs are a critical factor. For example, servicing times in the first year are lower for electric vans, averaging 0.74 hours compared to 1.05 hours for ICE vehicles and 1.15 hours for hybrids. By the fourth year, ICE vehicles show the best servicing times at 1.19 hours, while electric vans and hybrids increase to 1.41 hours and 1.42 hours respectively. Meadows further noted:

There is a strong technical argument that while electric vans are more expensive to buy, their reduced number of wear parts should mean that they spend less time being serviced, and the data is bearing that out in general terms.

Vehicle Off-Road (VOR) times provide additional insights into operational efficiency. In the first year, ICE vehicles have the lowest VOR time at 1.82 hours, whereas hybrids record the highest at 2.14 hours. By the fourth year, hybrids improve to the best VOR times at 2.38 hours, compared to 2.63 hours for ICE vehicles and 2.91 hours for electric vans. These figures are crucial, as they directly affect fleet availability and revenue-generating potential, making them a key consideration in lifecycle cost assessments.

Lifecycle Cost Analysis for UK Fleets

After addressing the environmental impact, understanding lifecycle costs is essential for making well-informed decisions in fleet management.

Well-to-Tank and Tank-to-Wheel Cost Contributions

In the UK, lifecycle assessments for fleet operations are typically divided into three main phases: vehicle production (manufacturing), operation (use phase), and end-of-life (disposal and recycling). Among these, the operational phase tends to receive the most attention from fleet managers, and it’s further split into two key components.

The first is Well-to-Tank (WTT), which covers the costs of producing and delivering fuel or energy. The second, Tank-to-Wheel (TTW), focuses on energy efficiency and consumption during vehicle use. For internal combustion engine vehicles, these two elements dominate lifecycle analyses, as the fuel chain and tailpipe efficiency significantly influence both environmental impact and operational expenses.

Studies carried out for the UK Department for Transport and the European Commission have evaluated a wide range of vehicle types, fuels, and electricity supply chains to support this analysis. This thorough approach helps fleet managers weigh the balance between upfront manufacturing costs and long-term operational expenses.

These insights form the foundation for methods that predict total ownership costs with greater accuracy.

Hybrid-LCA Methods for Cost Forecasting

To build on this understanding, fleet managers often rely on Hybrid-LCA methods to forecast costs. These methods combine lifecycle data with economic modelling to calculate the Total Cost of Ownership (TCO). By integrating environmental metrics with economic factors like energy prices and resale values, this approach offers a more holistic view of costs.

The UK's Transport Analysis Guidance (TAG) plays a key role in this process. TAG uses speed-emission and fuel consumption curves to estimate operational costs across various vehicle types, including ultra-low emission vehicles. These models consider how average speeds impact fuel and energy consumption, with updated guidance now incorporating specialised curves for emerging technologies, such as catenary battery electric heavy goods vehicles. The Department for Transport explains:

TAG provides information on the role of transport modelling and appraisal and how the transport appraisal process supports the development of investment decisions to support a business case.

Additionally, the UK government’s lifecycle analysis framework evaluates greenhouse gas emissions and operational impacts for all road vehicle categories up to 2050. This framework is regularly updated to reflect changes in the carbon intensity of the UK electricity grid and advancements in battery technology.

How Telematics Reduces Lifecycle Impacts

Telematics has proven to be a game-changer in tackling the environmental challenges associated with vehicle use. By integrating real-time monitoring and data-driven insights, telematics helps reduce emissions during the operational phase, as highlighted by lifecycle assessments.

Eco-Driving Analytics and Fuel Efficiency

One of telematics' standout features is its ability to address emissions during the Tank-to-Wheel phase. In-cab devices track driver habits like harsh acceleration, idling, and abrupt braking - behaviours that lead to higher fuel consumption and emissions. By providing instant feedback, these systems encourage drivers to adopt smoother, more fuel-efficient techniques. This is especially crucial in urban areas, where delivery vehicles are responsible for around 25% of CO₂ emissions, 33% of NOₓ emissions, and 50% of particulate matter. Overall, road transport contributes to over 70% of total emissions.

Real-Time Data for Lifecycle Optimisation

Beyond improving driver behaviour, telematics enhances fleet operations by leveraging real-time data. This includes optimising routes using live traffic updates, managing charging schedules, monitoring battery health, and enabling predictive maintenance. Predictive maintenance, in particular, can lower repair costs significantly - by as much as 50% for electric vehicles. These measures collectively minimise mileage, idle time, and operational inefficiencies, making fleets more sustainable.

For instance, GRS Fleet Telematics provides eco-driving analytics and real-time tracking starting at £7.99 per vehicle per month, offering UK fleets an affordable way to cut fuel consumption and reduce their environmental footprint.

Comparing Conventional and Telematics-Optimised Fleets

The difference between conventional fleets and those equipped with telematics is stark. Diesel fleets relying on static routing and manual oversight are more prone to inefficiencies like higher fuel use and congestion-related delays. On the other hand, telematics-optimised fleets use dynamic scheduling and real-time data to maintain efficiency, even in stop-and-go urban traffic.

| Lifecycle Phase | Conventional Diesel Fleet Impact | Telematics-Optimised Fleet Mitigation |

|---|---|---|

| Production | High carbon debt from vehicle manufacturing | Data-driven fleet sizing reduces unnecessary vehicle production |

| Use (Tank-to-Wheel) | High emissions; fuel economy drops in congestion | Real-time route optimisation and eco-driving analytics maximise efficiency |

| Use (Well-to-Tank) | Indirect emissions from fuel extraction and transport | Reduced total fuel demand through efficiency gains |

| Maintenance | Higher costs due to complex engine systems | Predictive maintenance reduces waste and extends vehicle lifespan |

| End-of-Life | Potential for 17% GHG savings through recycling | Monitoring component health optimises remanufacturing timing |

Data source:.

For perspective, hybrid electric SUVs typically emit 200–240g CO₂-equivalent per kilometre over their lifecycle. By addressing inefficiencies overlooked by static systems, telematics can substantially reduce these emissions.

As researchers Lei Yang, Caixia Hao, and Yina Chai point out:

ETs show more advantages than DTs when the frequency of use is higher or when the driving environment is more congested.

This highlights the critical role telematics plays in improving fleet performance, particularly in challenging urban conditions.

Conclusion

A lifecycle assessment sheds light on the true environmental impact of UK fleet operations - from manufacturing all the way to disposal. Current data underscores a stark reality: UK road vehicles are the largest contributors to domestic greenhouse gas emissions. For fleet operators, this means shifting focus beyond just fuel consumption to make decisions that support long-term sustainability.

Battery electric vehicles (BEVs) offer a compelling advantage, cutting lifetime greenhouse gas emissions by 40–50% compared to petrol-powered cars. This makes the transition to Ultra-Low Emission Vehicles (ULEVs) a critical step forward. However, understanding real-world driving habits and charging behaviours is essential to determine which fleet vehicles are best suited for electrification. By using accurate data and standardised conversion factors, fleet managers can measure carbon footprints precisely and uncover cost-saving opportunities. These insights, paired with telematics, pave the way for operational improvements.

Telematics builds on lifecycle data by providing real-time, actionable insights that help bridge the gap between environmental goals and daily fleet operations. With tools to reduce emissions, boost fuel efficiency, and extend vehicle lifespans, telematics transforms sustainability into practical outcomes. For instance, GRS Fleet Telematics offers these capabilities at an affordable £7.99 per vehicle per month, making fleet optimisation more accessible for UK businesses. Features like eco-driving analytics and route optimisation target inefficiencies that can otherwise dilute the environmental benefits of cleaner vehicles.

As outlined, achieving lower lifecycle impacts requires a combination of the right vehicle technologies, a deep understanding of usage patterns, and data-driven optimisation. With the UK striving towards its Net Zero targets, fleet operators who embrace lifecycle thinking and telematics-driven strategies will be better positioned to meet both environmental and operational objectives.

FAQs

How do the lifecycle environmental impacts of electric vehicles compare to diesel vehicles in UK fleets?

Electric vehicles (EVs) tend to have a lower lifecycle environmental impact compared to diesel vehicles in UK fleets, especially when it comes to greenhouse gas emissions during use. This advantage is largely due to the UK's steadily decarbonising electricity grid, which continues to reduce the carbon footprint of EVs as time goes on.

That said, the production of EVs - particularly the manufacturing of their batteries - can result in higher emissions upfront compared to diesel vehicles. However, these initial emissions are usually balanced out over the course of the vehicle's operational life, as EVs produce no tailpipe emissions. With the UK moving towards cleaner energy sources, EVs are becoming an increasingly eco-friendly choice for fleet operations in the long run.

How does telematics help reduce the environmental impact of UK fleet operations?

Telematics helps fleet operations minimise their environmental impact by offering real-time data for smarter vehicle management. By tracking elements such as vehicle location, driving habits, and route efficiency, fleet managers can reduce unnecessary mileage, idling, and fuel use. This directly cuts emissions and aligns with sustainability targets.

It also supports the shift to electric vehicles (EVs) by monitoring charging patterns and performance, simplifying the integration of EVs into fleets while reducing dependence on fossil fuels. Beyond that, telematics aids in meeting environmental regulations, streamlines carbon reporting, and boosts vehicle security, cutting down the environmental toll linked to theft and replacements. In the UK, it’s a key tool for improving operational efficiency and lowering carbon footprints in fleet management.

How can fleet managers reduce emissions while managing costs effectively?

Fleet managers can balance cutting emissions with managing costs by focusing on the total cost of ownership (TCO). This means looking beyond just the purchase price to include running costs, maintenance, and end-of-life disposal. At the same time, prioritising vehicles with lower emissions - like electric or renewable fuel-powered options - can make a big difference.

Implementing smart fleet management strategies is another effective approach. Practices such as efficient route planning, optimising how vehicles are used, and keeping up with regular maintenance can reduce both expenses and emissions. Tools like advanced telematics systems - such as those provided by GRS Fleet Telematics - offer valuable data on vehicle performance and emissions. These insights allow fleet managers to make informed, sustainability-focused decisions.

Taking a broader view by assessing full lifecycle emissions - from manufacturing to disposal - can reveal further ways to minimise environmental impact. Opting for vehicles with lower greenhouse gas emissions and taking advantage of government incentives for low-emission technologies can also help create a more cost-effective and environmentally friendly fleet.