How Last-Mile Delivery Software Improves Route Planning

Last-mile delivery software automates route planning to cut mileage and fuel costs, boost ETA accuracy, reduce failed deliveries and improve on-time rates.

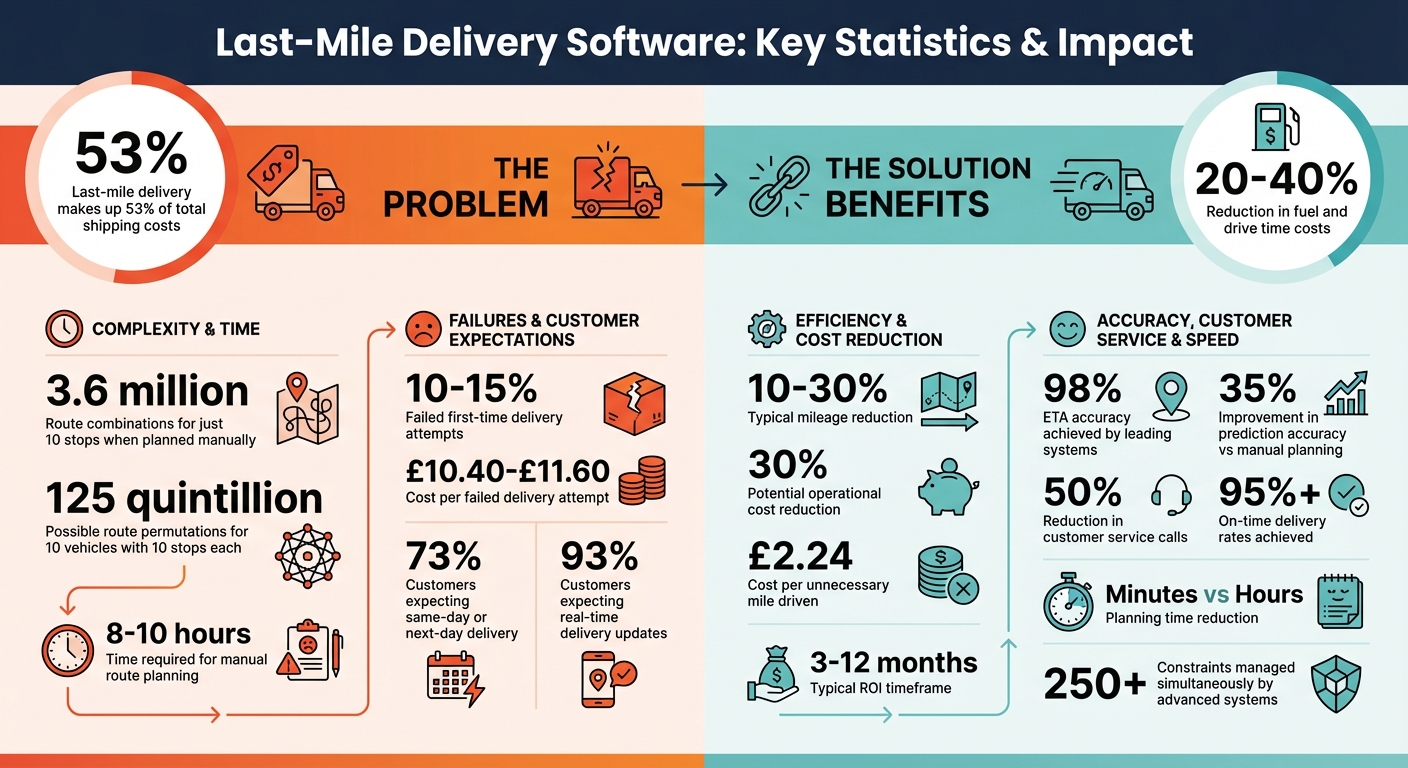

Last-mile delivery is expensive, making up 53% of shipping costs, and manual route planning often fails to keep up with its complexity. Software solutions simplify this process by using advanced algorithms to optimise routes, reduce costs, and improve delivery times. Here's what makes these tools indispensable:

- Cost Reduction: Automated routing cuts fuel and drive time by 20–40%, saving money and reducing unnecessary mileage.

- Efficiency: Manual planning for 10 stops involves over 3.6 million route combinations, making software essential for handling such complexity.

- Customer Expectations: With 93% of customers expecting real-time updates, these tools provide accurate ETAs and live tracking, improving satisfaction.

- Dynamic Adjustments: Real-time recalculations help manage traffic, weather, and delays without manual intervention.

- Failed Deliveries: Each failed attempt costs around £10.40. Route planning tools minimise these by improving accuracy.

Last-Mile Delivery Software Impact: Key Statistics and Cost Savings

How last mile delivery software increases efficiency and reduces costs

Main Challenges in Last-Mile Route Planning

Manual route planning struggles to keep pace with the demands of modern delivery systems. To put it into perspective, planning just 10 stops offers millions of route combinations. But when you scale that to 10 vehicles with 10 stops each, the number skyrockets to over 125 quintillion possible permutations. These staggering numbers highlight the immense complexity and computational demands involved, setting the stage for the operational challenges that follow.

Time Constraints and Traffic Management

Today’s customers have high expectations, with many insisting on two-hour delivery windows and 73% expecting same-day or next-day service. These tight timeframes force planners to prioritise specific delivery slots over geographical efficiency, leading to routes that crisscross entire cities. Add to this the unpredictability of urban congestion, school runs, roadworks, and weather disruptions, and it becomes clear why static, manually planned routes often fall apart once drivers hit the road. Even a single traffic incident can ripple through the schedule, throwing off multiple deliveries .

The challenges shift depending on the environment. In densely packed city centres, planners must contend with congestion charges, Clean Air Zones, and strict regulations on loading times and locations . Suburban areas bring their own hurdles, such as narrow roads and streets restricted during school hours, while rural routes face long distances between stops and weather-related access issues. Phil West, Director at Pegasus Couriers, sums it up well:

Route planning in the UK only delivers full value when the last leg is treated as a design problem, not an afterthought.

Vehicle Capacity and Delivery Zones

Another issue lies in mismatched vehicle capacity. Some drivers return to the depot with unused space in their vans, while others are overloaded and struggle to complete their routes within their shift limits. This imbalance often stems from poorly defined delivery zones and a lack of consideration for real-world constraints like vehicle weight limits, low bridges, and emission zone restrictions . When delivery density doesn’t align with vehicle capabilities, the result is wasted capacity, missed deliveries, and a high rate of failed first-time delivery attempts - currently affecting 10–15% of cases.

Manual Planning Inefficiencies

Planning complex delivery routes manually can take 8–10 hours, often relying on outdated tools like spreadsheets and static maps. These methods can’t account for live traffic updates or last-minute order changes . The inefficiencies add up quickly: each extra mile driven costs an estimated £2.24, with fuel alone accounting for about 25% of that cost. On average, manually planned routes result in 10% more mileage than necessary . This is why automation is no longer optional for modern fleets. As Jim Endres from Aptean puts it:

If you're not getting delivery route planning exactly right, you're throwing money, customers and competitive advantage down the drain.

How Last-Mile Delivery Software Improves Route Planning

Last-mile delivery software takes the headache out of route planning by automating what used to be a labour-intensive, manual process. Tasks that could take a human planner hours to complete are now handled in minutes, thanks to specialised algorithms capable of processing millions of calculations. These systems juggle variables like traffic patterns, delivery time slots, vehicle dimensions, emission zones, and even driver expertise - all at once.

Route Planning Algorithms

At the heart of this software are powerful algorithms designed to tackle complex operational constraints. For instance, they can account for vehicle height and weight restrictions to avoid low bridges, adhere to Clean Air Zone regulations, and sequence deliveries based on time-critical commitments. Advanced systems manage over 250 constraints simultaneously, ranging from load capacity to special handling needs for perishable items. They can even divide large delivery areas into smaller clusters, reducing route overlap and maximising the number of deliveries per trip.

AI-powered models further enhance this process by analysing historical data, improving prediction accuracy by more than 35% compared to manual planning. These models adapt based on past performance, incorporating real-world factors like typical traffic conditions at specific times of day. This adaptability ensures the software can make responsive adjustments when unexpected challenges arise.

Real-Time Dynamic Routing

Dynamic routing takes these algorithms a step further by continuously updating routes as conditions change. Using live data - such as traffic updates, weather reports, and road closures - the software instantly recalculates routes to minimise delays. For example, if an accident causes a motorway shutdown or roadworks appear unexpectedly, the system automatically reroutes vehicles, sending updated instructions to drivers without requiring manual input from dispatchers.

This real-time adaptability extends beyond the depot. As new orders come in throughout the day, the software integrates them seamlessly into existing routes. By connecting with in-vehicle telematics, it creates a feedback loop that compares planned routes with actual road performance. Dispatchers can quickly identify and address discrepancies, while the system automatically updates customers with revised ETAs when delays occur. Integration with advanced tracking tools, like those from GRS Fleet Telematics, adds another layer of precision by providing real-time vehicle location data.

Faster Planning and Improved Accuracy

One of the biggest advantages of route optimisation software is how it slashes planning time - from hours to mere minutes - giving staff more time to handle exceptions. But speed isn’t the only benefit; accuracy is equally critical. Leading systems achieve up to 98% ETA accuracy by combining historical traffic data with real-time updates.

This level of precision doesn’t just save time - it saves money. Automated planning can cut fleet mileage by over 10%, which is significant when you consider that every unnecessary mile costs around £2.24. With fuel expenses making up roughly 25% of the cost per mile, even minor reductions in mileage can lead to substantial savings. Additionally, accurate ETAs help reduce "Where is my order?" calls by up to 50%, lowering the costs associated with customer service. As Jim Endres from Aptean puts it:

The software does in minutes what even the most brilliant transportation planner couldn't do, even in hours.

Core Features of Last-Mile Delivery Software

The best last-mile delivery software combines real-time tracking, dynamic routing, and performance analytics into a single, responsive platform. These features work together seamlessly to adjust delivery operations as conditions evolve throughout the day.

Real-Time Tracking and Monitoring

With GPS tracking, fleet managers can see the exact location of every vehicle in real time. This allows them to compare planned routes against actual performance, quickly spotting when drivers stray from the optimal path. It also tracks key data like vehicle speed, idling time, and driver behaviour - factors that directly impact fuel efficiency and delivery timeliness.

This level of visibility is especially helpful when customers ask about their orders. Instead of estimating delivery times, dispatchers can provide precise ETAs based on live vehicle locations and current traffic conditions. Proactive notifications about delays can cut up to 50% of "where is my order?" calls, which typically cost between £7 and £13 each to handle. Tools like GRS Fleet Telematics take this a step further, using dual-tracker technology to maintain visibility even in areas with weak signal coverage or if a primary tracker fails.

Dynamic Route Recalculation

Dynamic route recalculation uses live data to continuously update delivery routes. Since initial plans can quickly become outdated due to traffic jams, road closures, accidents, or weather, this feature ensures routes are always optimised. The software automatically adjusts routes in real time, sending new instructions directly to drivers' mobile devices - no manual intervention needed. It can also reassign delivery stops to the driver who can get there fastest based on live conditions.

Proof-of-Delivery and Performance Metrics

Electronic proof-of-delivery (ePOD) replaces outdated paper records with digital signatures, time-stamped photos, and geolocation data. This creates a reliable audit trail to resolve disputes over missed or damaged deliveries and supports the contactless delivery options that many customers now prefer.

Performance dashboards provide a wealth of data, including fuel consumption, on-time delivery rates, service times, and deliveries per driver. These metrics help managers identify problem areas, such as consistently delayed routes or drivers who may need additional training. They also highlight inefficiencies that waste resources, guiding decisions to improve operations. For instance, Zenith Hygiene Group used such insights to reduce insurance claims from £214,000 to £88,000 in one year, while also saving £90,000 on fuel costs. The key is choosing software that presents this data in an easy-to-understand format, enabling managers to spot trends and make smarter fleet decisions.

Implementing Last-Mile Delivery Software in Your Fleet

Rolling out last-mile delivery software can deliver a return on investment (ROI) within 3 to 12 months. To get there, a structured approach is essential - one that ensures your data is well-prepared, your drivers are on board, and you’ve set clear metrics for tracking progress.

Data Preparation and System Integration

Before diving into the software, gather and centralise all operational data. This includes delivery addresses, order details, vehicle capacities, driver schedules, and any customer-specific requirements. Having this information in one place makes the transition smoother and ensures the software can function effectively.

Next, connect the software to your existing systems. Many modern platforms are designed to integrate seamlessly with e-commerce tools like Shopify, ERP systems such as Sage 200 or Xero, and warehouse management systems via APIs. If direct integration isn’t an option, you can often upload order data using CSV files.

For fleets in the UK, pairing the software with a telematics solution like GRS Fleet Telematics (https://grsft.com) offers advanced tracking features. These include real-time performance comparisons, live ETA updates, and proactive delay notifications. For instance, Iceland Foods enhanced their fleet's efficiency by combining Trakm8's telematics with route optimisation software. Before you go live, take advantage of the software’s "what-if" modelling tools. These allow you to simulate scenarios - like adding new distribution centres or testing different vehicle types - to see how they might affect your operations.

Once your systems are integrated and your data is ready, it’s time to focus on preparing your team for the change.

Driver Training and Adoption

Introducing new technology can sometimes meet resistance from drivers. Training is key to overcoming this. Show drivers how the software can make their lives easier, from ensuring predictable finish times to reducing stress and improving safety. Well-trained drivers play a crucial role in smoother route execution and help maximise the benefits of route optimisation.

Take Marigolds & Onions, a large catering company, as an example. They achieved full ROI within just three months by ensuring their drivers understood how the system would reduce reliance on third-party couriers and stabilise route planning. In the early months, the company cut its use of external couriers by 50%, giving permanent drivers more consistent work.

"The best driver debriefs are not 'us vs. them' discussions. They are about manager and driver teaming up to create a win-win outcome for better truck route planning."

– Jim Endres, Regional Account Director, Aptean

Regular feedback sessions are another important step. Drivers can share challenges they encounter, such as delays at specific locations or recurring traffic problems. This feedback helps refine the software’s data and improves future planning. Post-route debriefs should focus on solving problems rather than assigning blame, using telematics data to identify areas for improvement.

Once drivers are trained and engaged, the focus shifts to monitoring performance and making continuous improvements.

Performance Monitoring and Improvement

Set clear KPIs before implementing the software. Metrics like cost per mile, on-time arrivals, fuel usage, and deliveries per driver are essential benchmarks. For example, Corporate Solutions tracked these after adopting Webfleet telematics and saw an 8.1% reduction in fuel costs alongside a 9.2% improvement in fleet MPG.

Real-time dashboards replace outdated manual spreadsheets, offering a transparent way to monitor route adherence and fleet efficiency. Tracking planned versus actual stops highlights route deviations, while monitoring fleet capacity use reduces empty miles. Metrics like drops per shift can also provide insight into driver productivity.

The data gathered often reveals opportunities for cost and fuel savings. By regularly reviewing KPIs, adjusting routes based on new data, and involving drivers in discussions, fleets can continuously refine their operations. This ongoing process ensures that last-mile delivery becomes not just efficient but consistently better over time.

Measuring the Impact of Route Planning Software

Once you've implemented route planning software, it's crucial to track key metrics. These numbers help you understand whether the solution is delivering on its promises - cutting costs, improving efficiency, and boosting customer satisfaction. They also highlight areas where further tweaks might be necessary. Let’s dive into how these metrics translate into real-world gains, from cost savings to operational improvements.

Cost Savings and Fuel Efficiency

One of the most immediate benefits of route planning software is cutting down on fuel and operational costs. By eliminating unnecessary mileage, fleets can reduce expenses by up to 30%. Fewer miles mean less fuel burned and less wear and tear on vehicles.

Take AKI Group, for instance - they saved £1 million annually on transport costs and increased deliveries per vehicle by 164% after adopting route optimisation software. Similarly, Martin Brower managed to cut 900,000 lbs of CO₂ from its emissions by reducing mileage.

Telematics plays a vital role here. By tracking driver habits - like idling, harsh braking, and speeding - fleet managers can pinpoint and correct behaviours that waste fuel. This kind of monitoring helps identify patterns that lead to higher costs, such as mileage deviations, which directly impact fuel consumption and operational expenses.

Another area where costs add up is failed deliveries. In the UK, a failed delivery attempt costs around £11.60, and nearly 6% of deliveries fail on the first try. By improving route accuracy and offering reliable ETAs, companies can significantly cut down on these expensive redeliveries. With the insights provided by the software, businesses can refine their processes and maintain long-term cost control.

On-Time Delivery and Customer Satisfaction

Timely deliveries are a cornerstone of customer satisfaction, and route planning software can make a noticeable difference. Leading logistics operations often achieve on-time delivery rates of 95% or more, and optimised routing can improve this metric by 12% to 18% within just a few months.

For example, Colorado Boxed Beef saw nearly perfect customer satisfaction after implementing automated route planning, thanks to more reliable delivery schedules. Additionally, features like dynamic ETAs and proactive notifications can reduce "Where Is My Order" (WISMO) calls by up to 40%.

"Since adding Onfleet, we have more confidence in our capacity, and that's translated into us providing a better service to guests whilst being more efficient."

– Chris Farr, E-Commerce Manager, The United Family

Digital proof-of-delivery systems further enhance the customer experience, cutting dispute resolution times by 60%. Real-time tracking and updates build trust, with 93% of consumers expecting proactive notifications about their orders, and 70% saying they’re unlikely to return after a poor delivery experience. Metrics like First Attempt Delivery Success Rate (FADR) and Order Accuracy Rate are particularly useful here. A FADR of 90% or higher and order accuracy rates above 98% show where the software is making the biggest impact. These insights not only improve operational efficiency but also strengthen customer trust.

Reduced Planning Time and Mileage

Beyond improving customer satisfaction, route planning software simplifies day-to-day operations by cutting down on planning time and reducing overall mileage.

Manual route planning can be a slow and error-prone process. With optimisation software, even complex routing tasks can be completed in under 15 minutes. For example, Blackheath Products reduced their daily planning time by 75%, while HAVI Taiwan brought peak-season planning down from 18 hours to just 15 minutes.

Optimised routes also lead to significant mileage reductions - typically between 10% and 30%. Some fleets have reported savings of 20% to 40% on fuel and drive time. Frozen Food Express, for instance, managed to reduce its 700-vehicle fleet by 10% after adopting route optimisation. Similarly, United Supermarkets found that Onfleet's software allowed them to handle a 50% increase in delivery capacity with their existing fleet, all while maintaining on-time delivery.

To fully understand these benefits, compare planned and actual performance. Integrating telematics data with your route planning software lets you monitor key metrics like total fleet miles, planning time, fuel costs, and on-time delivery rates. This ongoing analysis ensures your fleet operates as efficiently as possible.

Conclusion

Last-mile delivery software streamlines route planning, transforming a process that once took hours into one completed in mere minutes. It also helps cut fuel expenses by 20–40%. By adjusting routes in real time to account for traffic, weather conditions, or road closures, it ensures fleets maintain top efficiency, even when unexpected challenges arise.

This level of efficiency doesn’t just lower operational costs; it creates a noticeable financial impact. Smarter routing addresses high delivery expenses and reduces costly failed delivery attempts. At the same time, better vehicle utilisation and shorter routes lead to improved on-time delivery rates, which naturally enhances customer satisfaction.

The benefits go beyond cost reduction. Features like real-time tracking and digital proof-of-delivery provide actionable data that can help businesses fine-tune their operations. With these insights, companies can grow without needing to scale up administrative resources.

Additionally, proactive updates and accurate delivery time estimates cater to the modern customer’s expectations. Transparent communication builds trust, fostering loyalty and encouraging repeat business.

For UK businesses aiming to cut costs while keeping customers happy, investing in last-mile delivery software is a smart move with long-term benefits.

FAQs

How can last-mile delivery software help lower fuel costs and reduce delivery times?

Last-mile delivery software plays a key role in cutting fuel costs and shortening delivery times. By optimising routes in real-time, it ensures drivers follow the most efficient paths, helping to minimise unnecessary mileage, idling, and detours. In fact, this can lead to a reduction in fuel consumption by more than 10% in many instances.

With better delivery schedules and improved fleet efficiency, businesses can handle more deliveries in less time while keeping operational expenses in check. This approach not only enhances productivity but also promotes a more eco-friendly way of managing logistics.

How do real-time updates enhance delivery accuracy?

Real-time updates are essential for ensuring delivery accuracy, as they enable on-the-fly route adjustments. These updates help drivers navigate around sudden disruptions like traffic jams, bad weather, or road closures, keeping deliveries on track.

By maintaining flexibility, real-time updates minimise the chances of missed delivery slots or failed attempts. This doesn’t just enhance the customer experience - it also improves fleet efficiency, cutting down on wasted time and fuel.

How does route planning software improve customer satisfaction?

Route planning software plays a key role in boosting customer satisfaction by ensuring deliveries are timely and dependable. By calculating the most efficient routes, it helps reduce delays and provides precise delivery windows, making it easier for customers to organise their day with confidence.

Moreover, the use of optimised routes reduces disruptions and enhances delivery reliability. This creates a smoother experience for customers, building trust and strengthening relationships. When deliveries consistently meet or even surpass expectations, it paves the way for long-term loyalty.