How Telematics Improves Maintenance Scheduling

Telematics ends guesswork—use real-time vehicle data to schedule maintenance, cut downtime and ensure compliance.

Telematics transforms vehicle maintenance from rigid schedules to data-driven decisions. By monitoring real-time engine hours, fault codes, and usage patterns, it ensures servicing happens when genuinely needed - not based on arbitrary timelines. This reduces downtime, prevents costly breakdowns, and cuts unnecessary expenses.

Key Points:

- Unplanned Downtime Costs: A single vehicle breakdown can cost nearly £6,000, including lost productivity and repairs.

- Mileage-Based Issues: Fixed schedules don’t account for heavy wear or idling, leading to over-servicing or missed maintenance.

- Compliance Made Easy: Automated reminders for MOTs and safety checks help fleets avoid fines and audits.

- Proactive Maintenance: Real-time alerts detect faults early, reducing downtime by up to 25%.

- Cost Savings: Predictive maintenance slashes emergency repairs and extends vehicle lifespan.

Switching to telematics-based maintenance isn’t just about keeping vehicles running; it’s about smarter decisions that save money and improve efficiency.

How Telematics can help schedule fleet service and preventative maintenance

Common Challenges in Construction Vehicle Maintenance Scheduling

Fleet operators in the UK are under immense pressure to meet deadlines and control costs. With only 8.5% of construction projects finishing on time and within budget, managing multiple sites and expensive machinery becomes a logistical nightmare. Traditional maintenance methods often fall short, leading to issues like unexpected downtime, poorly timed servicing, and compliance headaches.

Unplanned Downtime and Its Impact

When a construction vehicle breaks down unexpectedly, the financial impact is staggering. An idle commercial truck can cost up to £600 per day in lost productivity. Factor in the average unplanned repair cost of £4,000, and a single breakdown could set you back nearly £6,000. Reactive maintenance - waiting for obvious signs of trouble - only makes things worse, leading to costly repairs and delays that disrupt entire project schedules. Across a fleet, these incidents quickly add up, creating significant operational and financial strain.

To make matters worse, 25% of asset locations are unknown to managers at any given time, while 35% of operators report that over a quarter of their on-road assets are unavailable due to limited visibility. This lack of oversight can cripple operations. Tools like telematics can bridge this gap by improving asset tracking, enabling timely maintenance, and ensuring vehicles are deployed effectively.

Limitations of Mileage-Based Scheduling

Relying on mileage to schedule maintenance doesn’t account for how construction vehicles are actually used. For example, machinery like excavators or concrete mixers often operate intensively while stationary, piling up engine hours without covering much distance. Similarly, vehicles working on muddy construction sites endure very different stresses compared to those driving on motorways. Mileage-based maintenance treats them the same, leading to either unnecessary servicing (wasting resources) or missed maintenance windows (increasing the risk of breakdowns).

Manual odometer tracking adds another layer of complexity. It’s prone to human error and doesn’t provide insight into how hard a vehicle’s engine has been working. This outdated approach can leave operators blind to the real condition of their fleet.

Compliance Risks and Regulatory Requirements

UK fleet operators must juggle MOT deadlines, DVSA regulations, and stricter emissions standards. The rise of Clean Air Zones and London's Ultra-Low Emissions Zone means non-compliant vehicles face daily charges.

"By keeping on top of scheduled maintenance and quickly resolving issues, vehicles are inherently healthier, safer and go on to live for longer." - Barney Goffer, UK Product Manager, Teletrac Navman

The challenge lies in balancing manufacturer-recommended service intervals with the wear and tear of construction sites. 45% of equipment managers struggle to control maintenance costs, often caught between over-servicing (which drives up expenses) and under-servicing (which risks safety issues and compliance failures). Falling behind on maintenance can lead to hefty fines or penalties during audits.

Telematics offers a solution by delivering real-time, accurate data to guide maintenance decisions. With this level of insight, operators can avoid guesswork, reduce costs, and ensure compliance with regulatory standards.

How Telematics Enables Proactive Maintenance

Telematics has redefined how maintenance is managed. Instead of sticking to rigid schedules or waiting for dashboard warnings, fleet operators now leverage real-time data to understand vehicle performance. This allows construction fleets to tackle issues early, avoiding costly breakdowns.

Real-Time Data Collection and Monitoring

Telematics systems gather and transmit detailed vehicle data through hardware like Onboard Diagnostic (OBD) devices, engine interfaces, and external sensors. Using wireless networks, this information is sent to cloud-based platforms. The data covers critical performance metrics such as engine hours, mileage, fuel consumption, idling time, engine temperature, oil pressure, and tyre pressure. For stationary machinery, engine hours provide a more accurate measure of wear than mileage. Additionally, systems monitor CANbus data, including battery charge levels and AdBlue levels, helping to prevent engine derating and ensuring compliance.

Fault Detection and Automated Alerts

Building on this real-time data, telematics systems excel at spotting potential issues early. They can detect problems in engines, transmissions, sensors, and batteries - such as overheating or overcharging - long before they lead to breakdowns. Predictive analytics go beyond fault codes, analysing trends in RPM, oil pressure, and temperature to predict wear. For instance, a sudden increase in fuel consumption might indicate engine inefficiency or a fuel leak. Diagnostic trouble codes provide early warnings, enabling timely intervention.

Automated alerts are another key feature. Notifications are issued well in advance - 7 days or 1,000 miles before an issue is expected, and again at 3 days or 200 miles - allowing time to schedule repairs and source parts. This proactive strategy can boost vehicle uptime by up to 25%. These insights feed directly into maintenance systems, paving the way for smoother operations.

Integration with Maintenance Workflow

Once an issue is flagged, telematics integrates seamlessly with maintenance management systems. Through API connections, data is centralised, triggering immediate actions and streamlining responses across large construction sites. Modern platforms can consolidate data from over 22 different OEM and aftermarket telematics systems into a single dashboard. This means managers can oversee mixed fleets - from JCB excavators to Volvo trucks - without switching platforms. GPS data adds another layer, enabling technicians to receive not just alerts but also the exact location of the equipment, speeding up response times on expansive sites.

This level of integration simplifies scheduling, reduces downtime, and maximises asset use.

"If your goal is to improve billing and service scheduling, then you may only need location and usage monitoring."

– Tony Nicoletti, Director of Sales and Business Development, DPL America

To make the most of telematics, setting clear goals is crucial. Without a focused strategy, operators risk being overwhelmed by excess data that lacks actionable insights. By defining specific objectives - such as cutting fuel costs or preventing theft - fleets can configure their telematics systems to provide the most relevant information, ensuring smarter maintenance decisions.

Benefits of Predictive Maintenance Scheduling

Switching from reactive fixes to predictive maintenance can completely change how construction fleets operate. By tackling issues before they become major problems, predictive maintenance helps cut costs, improve efficiency, and boost both asset performance and safety.

Reduced Downtime and Unexpected Costs

Predictive maintenance, powered by real-time data, ensures vehicles are serviced exactly when necessary. Telematics systems can spot potential failures weeks in advance by analysing engine performance and fault codes [9,25]. This approach avoids the pitfalls of over-servicing and under-servicing [9,25]. For example, combining routine tasks like an oil change with a coolant flush reduces shop visits, keeping vehicles on the job. In construction equipment, sensors monitor hydraulic systems for early signs of fluid contamination or pump wear, preventing expensive overhauls and project delays [25,27]. AI-driven insights can cut unplanned downtime by as much as 30%. A great example is a European delivery SME that adopted the iMaintain platform in 2025. They reduced downtime by 28%, achieved a 95% compliance rate for preventive maintenance, and saved £85,000 in just one year.

"Predictive maintenance follows the data. Preventative maintenance follows a schedule." – CameraMatics

Improved Asset Utilisation

Real-time data ensures vehicles are serviced at the right intervals, extending their lifespan. Catching small issues early stops them from escalating into bigger problems that could shorten the working life of assets [2,25]. Predictive systems also help optimise fuel efficiency. For instance, underinflated tyres can reduce fuel economy by 2%, and clogged filters increase engine strain. Additionally, location and usage tracking allow managers to allocate equipment more effectively, cutting down on unnecessary rentals and preventing equipment hoarding. By 2025, nearly half (49%) of equipment operators were already using telematics to get the most out of their assets. Benson Systems, for example, used telematics to monitor driver behaviour and vehicle health, which led to a 15–20% reduction in insurance premiums through AI-driven feedback on reckless driving.

Better Compliance and Safety

Predictive maintenance doesn’t just keep vehicles running smoothly - it also helps meet regulatory standards and improves safety. By continuously monitoring critical components like brakes, tyres, steering, and lighting, fleets can stay compliant with UK MOT and DVSA requirements [29,9]. Real-time alerts for engine faults allow teams to prioritise repairs based on severity, preventing safety hazards and avoiding regulatory breaches. Digital maintenance logs and signatures provide a clear record for safety audits [29,30,2]. In a survey of transportation and manufacturing sectors, 95% of respondents said predictive maintenance improved at least one key area, such as uptime or safety. For construction fleets, tracking engine hours instead of mileage ensures heavy equipment and hydraulic systems remain in top condition and compliant [28,29].

"A vehicle with healthy brakes, tyres, fluids, and steering components is safer for everyone. PM tasks eliminate hidden risks and strengthen compliance with safety standards." – Simply Fleet

GRS Fleet Telematics Solutions for Maintenance Management

GRS Fleet Telematics helps construction fleets move from fixing problems after they occur to preventing them in the first place. With tools like real-time tracking, automated notifications, and cost-effective pricing, it ensures vehicles stay on the road while keeping expenses in check.

Real-Time Tracking and Data Insights

The system brings all vehicle data together in a cloud-based dashboard, giving fleet managers a clear picture of their fleet's overall health. It records odometer readings with precision, aligning maintenance schedules with actual usage. Diagnostic trouble codes (DTCs) are monitored to send instant alerts about mechanical or electrical issues. Fuel consumption data is also analysed - sudden increases can signal engine problems. To streamline operations, the platform generates digital work orders automatically when faults are detected. This combination of tracking and automation ensures maintenance is timely and efficient.

"By implementing predictive and preventative maintenance processes across their fleets, managers can help reduce downtime, prevent unexpected issues, and bring costs under control." – GRS Fleet Telematics

Customisable Alerts and Notifications

GRS Fleet Telematics allows managers to create alerts that fit their specific needs. Preventative alerts, based on odometer readings and engine hours, ensure routine servicing happens on time. Predictive alerts, on the other hand, focus on DTCs to catch potential issues early. Compliance reminders help fleets stay on top of MOT deadlines and other regulatory checks. Alerts are sent twice before services are due - once 7 days (or 1,000 miles) in advance and again 3 days (or 200 miles) prior. Additional features include geofence alerts for tracking site entries and exits, notifications for unauthorised vehicle use, and theft alerts. Impressively, GRS boasts a 91% recovery rate for stolen vans.

Affordable and Scalable Solutions

GRS Fleet Telematics offers three hardware options: Essential (£35), Enhanced (£79) with dual-tracker technology, and Ultimate (£99) featuring immobilisation. The software subscription is just £7.99 per vehicle per month, covering SIM data, full platform access, and a dedicated account manager. Installation is free when paired with GRS Fleet Graphics branding. Whether managing a small or large fleet, this solution is designed to provide powerful features at a reasonable price.

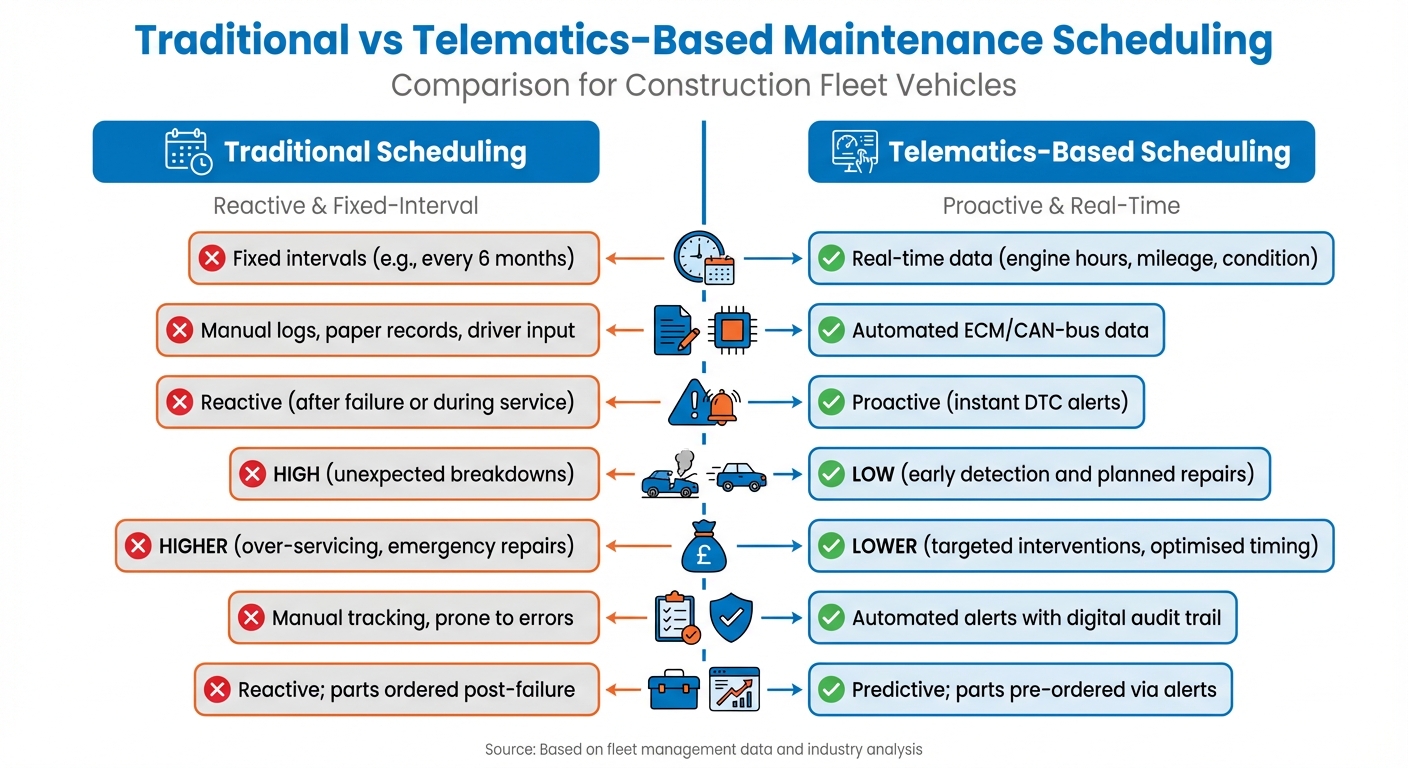

Comparing Traditional vs Telematics-Based Maintenance Scheduling

Traditional vs Telematics-Based Vehicle Maintenance Scheduling Comparison

Telematics-based maintenance flips the script on the old fixed-interval servicing model. Instead of relying on the "every six months or 10,000 miles" rule, it uses real-time data to determine when servicing is actually needed. Traditional methods often lead to unnecessary work or, worse, missed issues that crop up between scheduled checks. Telematics, on the other hand, taps into real-time data from the vehicle's engine control module (ECM), ensuring maintenance is based on actual wear and tear, not arbitrary timelines.

One of telematics' standout features is its ability to instantly detect diagnostic trouble codes (DTCs). This allows fleet managers to act quickly, addressing potential problems before they snowball into expensive repairs. Eli Demmer, Director of Business Solutions at Watco, put it this way:

"Moving from a periodic maintenance schedule to a data driven schedule has already resulted in significant maintenance cost savings".

This approach not only cuts down on the risk of breakdowns but also helps managers plan ahead for resources and parts.

Traditional systems often struggle with parts forecasting, leaving managers scrambling to order components after a breakdown occurs. Telematics changes the game by sending automated alerts that predict parts needs in advance. This proactive strategy minimises downtime and slashes emergency repair costs. A great example comes from West Coast Sand and Gravel, which used telematics to monitor engine idling across their fleet. Over just three months, they cut idling time by 37%, saving 5,205 gallons of fuel - worth around £14,300.

Comparison Table: Traditional vs Telematics-Based Scheduling

| Feature | Traditional Scheduling | Telematics-Based Scheduling |

|---|---|---|

| Timing Basis | Fixed intervals (e.g., every 6 months) | Real-time data (engine hours, mileage, condition) |

| Data Source | Manual logs, paper records, driver input | Automated ECM/CAN-bus data |

| Fault Detection | Reactive (after failure or during service) | Proactive (instant DTC alerts) |

| Downtime Risk | High (unexpected breakdowns) | Low (early detection and planned repairs) |

| Cost Impact | Higher (over-servicing, emergency repairs) | Lower (targeted interventions, optimised timing) |

| Compliance Accuracy | Manual tracking, prone to errors | Automated alerts with a digital audit trail |

| Resource Planning | Reactive; parts ordered post-failure | Predictive; parts pre-ordered via alerts |

Telematics doesn't just reduce downtime - it also simplifies compliance. Manual, paper-based systems make tracking MOT deadlines and inspections a headache, often leading to missed obligations. Telematics platforms solve this with automated reminders and a complete digital audit trail, ensuring all regulatory requirements are met without the usual fuss. From fault detection to resource planning and compliance, telematics takes the guesswork out of maintenance management.

Conclusion

Telematics has shifted maintenance scheduling from reactive guesswork to proactive planning. By leveraging real-time data, issues can be addressed before they escalate into major, costly breakdowns. Instead of sticking to fixed-interval servicing, vehicles now receive maintenance based on their actual condition. This approach not only reduces unnecessary work but also ensures problems are caught early, effectively tackling the challenges discussed earlier.

The financial benefits are hard to ignore. Mike Granruth from Trimble shared an example of a large construction fleet consuming 30,000 gallons of diesel weekly. By using telematics to cut idle time, the fleet achieved a 20% reduction in fuel consumption - saving 6,000 gallons per week. Over a year, this translates to savings of around £500,000.

Beyond cost savings, telematics enhances operational efficiency. For construction businesses managing mixed fleets, integrated platforms centralise data into a single dashboard. This simplifies fleet management and automates compliance tracking, providing a digital audit trail that makes regulatory adherence much easier. With the UK vehicle telematics market growing by over 18% annually through 2030, this technology is quickly becoming a necessity for modern fleet operations.

For construction fleets, advanced solutions like GRS Fleet Telematics offer impressive benefits. Starting at just £7.99 per month, it provides real-time tracking, customisable maintenance alerts, and dual-tracker technology with a 91% recovery rate for stolen vehicles. It even includes remote immobilisation to protect valuable machinery. Mark Richards, Operations Manager at BuildRight Construction, noted zero successful thefts since installation, with two attempted thefts successfully thwarted using the dual-tracker system.

The choice is straightforward: stick with manual logs and reactive repairs or embrace data-driven maintenance to minimise downtime, cut costs, and extend the lifespan of assets.

"You can never eliminate downtime because maintenance still needs to happen. But telematics helps an equipment manager pick a good time to schedule it when the downtime will be least impactful" – Ted Polzer, Case Construction

FAQs

How can telematics help reduce vehicle downtime and lower maintenance costs?

Telematics plays a key role in cutting vehicle downtime and lowering maintenance expenses through smart, data-driven fleet management. By tracking essential metrics like engine health, fuel consumption, and operating hours in real time, telematics systems allow you to schedule maintenance based on the actual condition of your vehicles instead of sticking to rigid, fixed intervals. This means you can skip unnecessary servicing and reduce the risk of unexpected breakdowns.

On top of that, telematics can spot early warning signs of potential problems, enabling timely repairs that prevent more serious damage and expensive fixes. With automated alerts and real-time diagnostics, maintenance happens precisely when it’s needed, helping to extend the life of your vehicles and ensuring they’re ready to perform when required. This focused approach doesn’t just save money - it also boosts the overall efficiency of your fleet.

What are the drawbacks of relying on mileage-based maintenance schedules?

Mileage-based maintenance schedules often fall short because they stick to fixed intervals, regardless of a vehicle's actual condition or usage. This can lead to unnecessary servicing, which wastes both time and money, or worse, it might overlook critical issues that develop between scheduled check-ups.

Relying solely on mileage ignores key factors like driving habits, the weight of loads carried, and external conditions - all of which significantly affect wear and tear. A smarter alternative is using telematics. This technology adapts maintenance to the real-world demands of your fleet, cutting down inefficiencies and helping vehicles stay in top shape.

How does telematics improve safety and ensure compliance in fleet management?

Telematics plays a key role in improving safety and ensuring compliance within fleet management. By offering real-time insights into vehicle performance and driver behaviour, these systems help operators stay on top of crucial factors like engine health, driving habits, and overall vehicle usage. This not only assists in meeting legal requirements, such as driver hours regulations and safety standards, but also reduces the likelihood of fines for non-compliance, all while encouraging safer driving habits.

On top of that, telematics enables proactive safety measures through live vehicle tracking, fault detection, and incident reporting. Fleet managers can swiftly address issues like mechanical problems or risky driving behaviours, cutting down potential hazards and enhancing safety across operations. By encouraging responsible driving and ensuring vehicles are well-maintained, telematics helps businesses stay compliant while protecting both their workforce and assets.