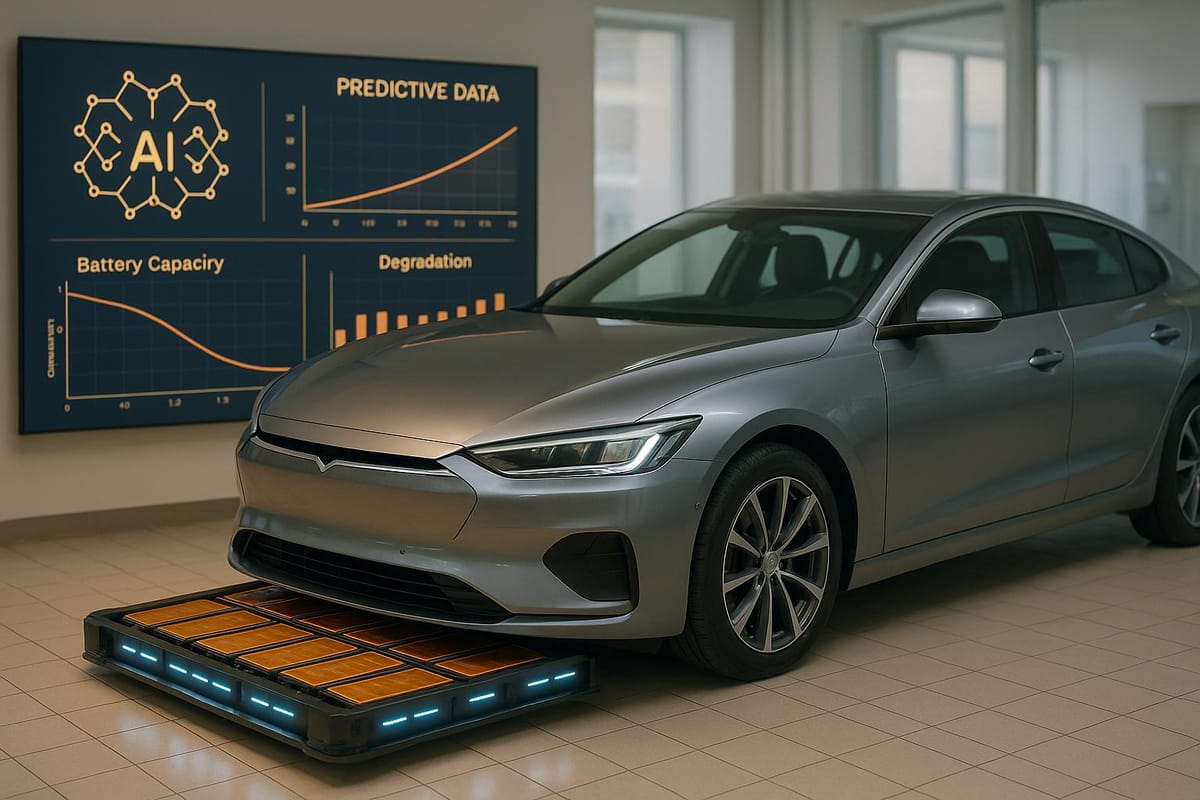

How AI Predicts EV Battery Degradation

AI revolutionises EV battery management by predicting degradation, optimising charging, and enhancing maintenance strategies for improved performance.

AI is reshaping how electric vehicle (EV) batteries are managed. Instead of reacting to problems after they occur, AI uses real-time data to predict battery wear, recommend better charging habits, and flag maintenance needs early. This approach helps fleet operators:

- Save money by avoiding unexpected breakdowns and costly repairs.

- Improve reliability by maintaining consistent battery performance.

- Extend battery life through smarter charging and usage patterns.

AI analyses data like voltage, temperature, and charging cycles to spot early signs of degradation. Paired with tools like GRS Fleet Telematics, fleet managers can monitor battery health, schedule maintenance effectively, and optimise operations - all from a single platform. This not only reduces costs but also supports long-term EV performance.

Unlocking Hidden EV Battery Data: The Power of AI + BMS!

Data Collection and Preparation for Battery Analytics

Accurate data is the cornerstone of effective AI predictions. Without precise and well-structured information on battery performance, even the most advanced algorithms can fall short. The journey to reliable battery degradation forecasting begins with gathering the right data and preparing it meticulously for analysis. This process lays the groundwork for AI-driven insights into battery health.

Types of Data Collected from EV Batteries

Modern EV batteries generate a wealth of data that reveals their health and performance over time. Among the most critical metrics are voltage measurements, which provide a snapshot of the electrical state of individual cells and the entire battery pack. These readings help pinpoint underperforming cells or potential faults before they escalate into larger issues.

Equally important is temperature data, as heat plays a major role in battery degradation. Sensors distributed across the battery pack monitor both ambient temperatures and the heat produced during charging and discharging. This data helps in understanding how thermal conditions impact the battery's lifespan.

Another key metric is the charge and discharge cycle data, which sheds light on how the battery is being used. Each cycle contributes to wear and tear, and by analysing factors like discharge depth, charging speed, and cycle frequency, AI systems can estimate cumulative stress and predict future capacity loss.

Current flow measurements track how electricity moves through the battery during use. Variations in current flow can signal changes in internal resistance, often a precursor to more serious degradation. Alongside this, capacity measurements assess how much energy the battery can store compared to its original specifications, giving a clear picture of its overall health.

Other useful data points include impedance readings, which measure internal resistance, and state of health indicators, which provide a holistic view of the battery's condition over time. Adding context to these metrics, information such as driving patterns, route characteristics, and charging behaviours helps AI models understand the factors influencing specific degradation trends.

Data Processing Techniques

Raw data from EV batteries often arrives incomplete or riddled with noise, making preprocessing a critical step before analysis. > High-quality input data is essential for building effective AI models in battery diagnostics.

Real-world data collection is not without its challenges. > Field data can be affected by seasonal temperature fluctuations, sensor malfunctions, electrical noise, and other interferences. To address these issues, data must be cleaned and standardised systematically.

Techniques like outlier removal filter out abnormal readings that deviate from expected ranges, while normalisation ensures that data from different measurements can be meaningfully compared. Data segmentation groups information based on conditions like vehicle type or usage scenarios, and feature extraction creates derived metrics - such as voltage drop rates or charging efficiency trends - that are more predictive of future battery performance.

Since battery data often comes in time series formats, time series processing is crucial. > Specialised neural networks excel at handling long-term dependencies and filling data gaps in time series. These methods enable AI systems to track long-term trends and manage intermittent data. Once refined, these datasets are transmitted via telematics for continuous monitoring and analysis.

Telematics Solutions for Data Collection

Telematics platforms act as a vital link between vehicle-generated data and AI analysis systems. By continuously monitoring battery performance in real-world conditions, these platforms ensure a steady flow of data for accurate predictions.

GRS Fleet Telematics is one such solution, designed to integrate seamlessly with EV battery monitoring systems. Using dual-tracker technology, it guarantees uninterrupted data collection, even if one system encounters issues. This ensures the data continuity necessary for reliable AI-driven insights.

The platform processes battery data in real time, identifying immediate concerns while also compiling historical datasets for long-term trend analysis. With 24/7 monitoring, it captures variations in battery performance across different times of day, weather conditions, and operational scenarios.

Moreover, GRS Fleet Telematics integrates with existing fleet management systems, combining battery health data with insights on route planning, driver behaviour, and maintenance scheduling. This holistic approach provides AI models with the context needed to understand degradation patterns and explore how operational adjustments might extend battery life.

With continuous, secure data collection and cloud-based storage, the platform ensures that battery performance data is always accessible for analysis. At the same time, secure transmission protocols protect sensitive fleet information, making advanced battery monitoring practical for fleets of all sizes.

AI Models for Predicting Battery Degradation

This section dives into how AI models are used to predict battery degradation, building on earlier discussions. These advanced models transform telemetry data into precise forecasts of battery health. This helps guide decisions about maintenance, replacement, and daily operations. The challenge lies in choosing the right techniques to tackle the complex and non-linear nature of battery wear and tear.

Machine Learning Techniques for Forecasting

Machine learning offers a range of tools for predicting battery degradation, each suited to different needs:

- Regression models: Linear regression works well for straightforward patterns, while polynomial regression handles more intricate trends. These models often form the backbone of prediction systems.

- Ensemble methods: By combining multiple regression techniques, ensemble methods improve prediction accuracy.

- Neural networks: Recurrent Neural Networks (RNNs) and Long Short-Term Memory networks (LSTMs) excel at detecting subtle patterns and long-term dependencies in battery data.

- Random Forests: These are particularly effective with noisy datasets, as they aggregate multiple decision trees to identify key factors driving battery degradation.

- Support Vector Machines (SVMs): SVMs are adept at working with high-dimensional sensor data, creating clear distinctions between different battery health states.

The choice of technique depends on the specific application. For day-to-day operational decisions, straightforward models like linear regression may be sufficient. However, for long-term planning, such as scheduling battery replacements, more advanced methods like neural networks are often necessary.

That said, machine learning models have their limits. They’re great at recognising patterns within their training data but can struggle when faced with unfamiliar scenarios. This is where combining AI with physical principles becomes essential.

Combining Physics-Based Models with AI

To address the limitations of data-driven models, hybrid approaches integrate AI with the fundamental principles of battery chemistry and physics.

- Physics-informed neural networks: These models embed equations based on battery chemistry directly into their structure. This ensures predictions align with scientific principles, avoiding unrealistic outputs like a battery’s capacity increasing over time.

- Digital twins: By blending real-time sensor data with physics-based simulations, digital twins provide continuously updated predictions of battery performance.

- Kalman filters: These combine theoretical physics-based predictions with AI-driven adjustments, offering a balance between scientific accuracy and adaptability.

This hybrid approach is especially useful for emerging battery technologies, where historical data may be scarce. By leveraging established physical principles, these models can make reliable predictions even for newer, less-tested chemistries. The result is not just more accurate forecasts but also a better understanding of why the model makes certain predictions.

The Importance of Explainable AI

For fleet operators, understanding AI-driven recommendations is crucial, especially when these involve expensive maintenance decisions. This is where explainable AI (XAI) comes into play, offering clarity and confidence in predictions.

- Feature importance analysis: This identifies which factors - like temperature, charging habits, or usage intensity - have the most significant impact on battery health.

- SHAP values: These provide detailed insights into how specific variables influence model predictions, breaking down complex relationships into understandable terms.

- Attention mechanisms: Used in neural networks, these highlight the most influential portions of input data for each prediction.

- Rule extraction techniques: These translate complex AI models into straightforward, human-readable rules, making it easier to act on the insights.

Explainable AI doesn’t just simplify decision-making; it also supports regulatory compliance by creating an audit trail. This transparency ensures that maintenance and replacement decisions can be justified, providing peace of mind to operators. By moving from reactive to proactive maintenance strategies, organisations can reduce costs and improve reliability over time.

Actionable Insights for Fleet Operators

Building on the predictive models discussed earlier, these insights offer fleet operators practical ways to streamline their operations. By leveraging real-time predictive analytics, operators can achieve measurable gains in cost savings, operational efficiency, and environmental responsibility.

Early Warnings and Maintenance Scheduling

AI systems excel at spotting subtle changes in battery performance that might otherwise slip under the radar. By analysing factors like voltage, temperature, and charging habits, these systems provide early warnings about potential issues before they escalate into major problems.

For example, GRS Fleet Telematics delivers real-time data that fuels these predictive insights. This allows fleet managers to plan maintenance during natural downtime, avoiding unexpected breakdowns. If AI detects a decline in battery capacity, it sends alerts and forecasts degradation, enabling timely interventions.

This approach is particularly useful for fleets navigating the UK's diverse terrain and weather. Batteries exposed to harsher winter conditions may require different care compared to those in milder climates. AI models account for these variables, tailoring recommendations to specific conditions.

Temperature-based alerts add another layer of protection. When batteries operate outside their optimal thermal range, AI can flag potential long-term damage. Fleet managers can then adjust charging schedules, improve thermal management, or modify routes to prevent further strain.

The financial advantages of early detection are significant. Proactive maintenance not only avoids costly emergency repairs but also preserves battery health, prolonging the lifespan of expensive commercial vehicles. Additionally, operators can refine charging practices to further extend battery life and reduce replacement costs.

Optimising Charging Schedules

AI-powered tools also tackle one of the biggest challenges in battery management: optimising charging schedules. Smart algorithms balance electricity costs, grid demand, and vehicle usage to improve both battery health and operational efficiency.

Charging during off-peak hours, guided by time-of-use tariffs, can immediately lower energy bills. For fleet operators, these savings can add up significantly over time.

Another critical factor is managing charging depth. Instead of fully charging batteries every day, AI systems recommend moderate charging levels based on usage patterns and environmental conditions. This not only extends battery life but also reduces the frequency and cost of replacements.

Seasonal adjustments are another key consideration. In colder months, AI might suggest higher initial charges to counteract reduced performance in low temperatures. Conversely, during summer, slower charging rates can help prevent heat-related wear and tear.

These AI-driven schedules integrate seamlessly with fleet management dashboards, combining location data with battery health insights to give operators full control over their fleet's performance.

Cost and Environmental Benefits

AI-driven battery management delivers benefits that go beyond operational efficiency - it also impacts the bottom line and the environment. Extending battery life delays costly replacements, while reducing unexpected downtime helps maintain consistent revenue streams.

There’s also the potential for better insurance terms and warranty conditions, thanks to optimised maintenance practices.

On the environmental side, extending battery lifespans reduces the need for new production, which consumes considerable energy and raw materials. By helping fleets get more out of their batteries, AI contributes to lowering the environmental footprint associated with manufacturing.

Additionally, coordinating charging schedules across entire fleets can prevent spikes in electricity demand, helping to stabilise the grid. This coordination also supports the integration of renewable energy sources, with potential financial rewards from energy suppliers for sustainable practices.

Integrating AI with GRS Fleet Telematics

Building on earlier developments in AI models, combining these systems with GRS Fleet Telematics takes predictive battery management to the next level. When AI-driven battery health monitoring is paired with GRS's fleet management tools, the result is a system that not only ensures consistent, high-quality data but also improves operational precision.

Streamlining Fleet Operations with AI

GRS Fleet Telematics simplifies AI-powered battery monitoring by incorporating real-time data on location, speed, and geofencing into its platform. Fleet managers can access all this information through a single dashboard that merges AI insights with critical vehicle metrics - no need to juggle between different systems.

The platform’s dual-tracker technology guarantees uninterrupted data flow, which is essential for accurate AI analysis. Additionally, it supports white-label branding, allowing larger fleet operators to maintain their corporate identity while benefiting from enhanced analytics and battery management tools. These features provide a strong foundation for evaluating the advantages of AI-enhanced monitoring compared to standard practices.

Comparison: Standard vs. AI-Driven Monitoring

AI-driven monitoring transforms battery management from a reactive process into a proactive one. Unlike traditional systems that rely on reactive alerts, AI-powered solutions provide early warnings about potential issues. This allows fleet operators to plan maintenance more effectively, reducing the risk of unexpected breakdowns. By integrating AI with GRS Fleet Telematics data, operators gain a deeper understanding of how vehicle usage affects battery performance, enabling more customised maintenance decisions.

The financial benefits are clear with GRS Fleet Telematics’ affordable £7.99 monthly subscription per vehicle. This cost-effective solution supplies the data needed for AI systems to operate effectively, helping to prevent expensive emergency repairs and premature battery failures.

AI-powered analytics also adapt to different operating conditions, offering tailored recommendations for battery care. This proactive approach empowers fleet operators to make smarter decisions, improving efficiency and cutting costs.

The reliability of GRS Fleet Telematics is well-established, with a 91% recovery rate for stolen vehicles. This ensures that AI algorithms receive consistent, high-quality data, which is crucial for effective predictive monitoring. Fleet operators using AI-enhanced insights through GRS systems report greater confidence in their maintenance strategies, benefiting from targeted recommendations that extend battery life and minimise operational disruptions.

Conclusion

AI-powered battery degradation prediction is changing the way fleet operators manage their electric vehicle (EV) assets. Instead of waiting for batteries to fail or relying on basic monitoring tools, AI introduces a precise, data-driven approach to battery management that delivers tangible results.

By combining machine learning with telematics data, fleet operators can tap into a powerful tool for predictive maintenance. AI analyses key factors like charging habits, temperature changes, and usage cycles to forecast battery issues well before they occur. This level of foresight enables fleet managers to implement smarter maintenance strategies across their operations.

For those looking to get the most out of their EV investments, GRS Fleet Telematics offers the critical data infrastructure needed for AI-powered battery monitoring. With its proven reliability, this system turns AI insights into actionable steps. Fleet managers can identify potential issues early, avoid costly emergency repairs, and minimise downtime. Maintenance can be scheduled during quieter periods, charging routines can be optimised to extend battery life, and decisions about vehicle replacements can be made with greater confidence. These strategies not only cut costs but also boost overall fleet efficiency.

AI-driven battery management also aligns with sustainability goals by extending battery lifespan. When batteries are maintained within ideal conditions and receive timely care, they perform better for longer, reducing the need for frequent replacements. This approach minimises waste and ensures that EV fleets deliver on their environmental promise.

FAQs

How does AI make predicting EV battery degradation more accurate than traditional methods?

AI has transformed how we predict EV battery degradation by leveraging advanced machine learning techniques, including neural networks, to process and analyse massive datasets. These tools can detect intricate patterns and relationships that conventional methods, often based on oversimplified assumptions, tend to overlook.

With more accurate predictions, AI enables better battery maintenance, prolongs battery lifespan, and cuts down costs. This means EV batteries can deliver consistent performance over time, providing actionable insights that improve fleet management and support long-term efficiency.

What data does AI use to predict EV battery health and performance?

AI uses several important data types to predict the health and performance of electric vehicle (EV) batteries. These include usage patterns, such as charging and discharging cycles, along with historical performance data collected over time. It also examines factors like temperature, voltage, current, and the state of charge (SoC) to evaluate the battery's condition and anticipate potential wear.

By analysing this data, AI can spot trends, detect early signs of degradation, and offer practical insights to help extend battery life and maintain efficiency. This predictive approach enables EV owners and fleet operators to make smarter decisions about maintenance and daily usage.

How do hybrid AI models using physics-based principles improve EV battery degradation predictions?

Hybrid AI models that integrate physics-based principles are reshaping how we predict electric vehicle (EV) battery degradation. By blending real-world data with established physical laws, these models deliver more precise and dependable forecasts than those based solely on data.

Through simulations of critical degradation processes - like capacity loss and thermal effects - these models can pinpoint potential problems early on. This doesn’t just improve prediction accuracy; it also supports proactive maintenance strategies. The result? Longer-lasting EV batteries and reduced overall costs in the long run.