Hardwired vs Plug-and-Play Trackers: Installation Guide

Compare hardwired vs plug-and-play van trackers — installation time, tools, tamper resistance and which option suits owned fleets or leased vehicles.

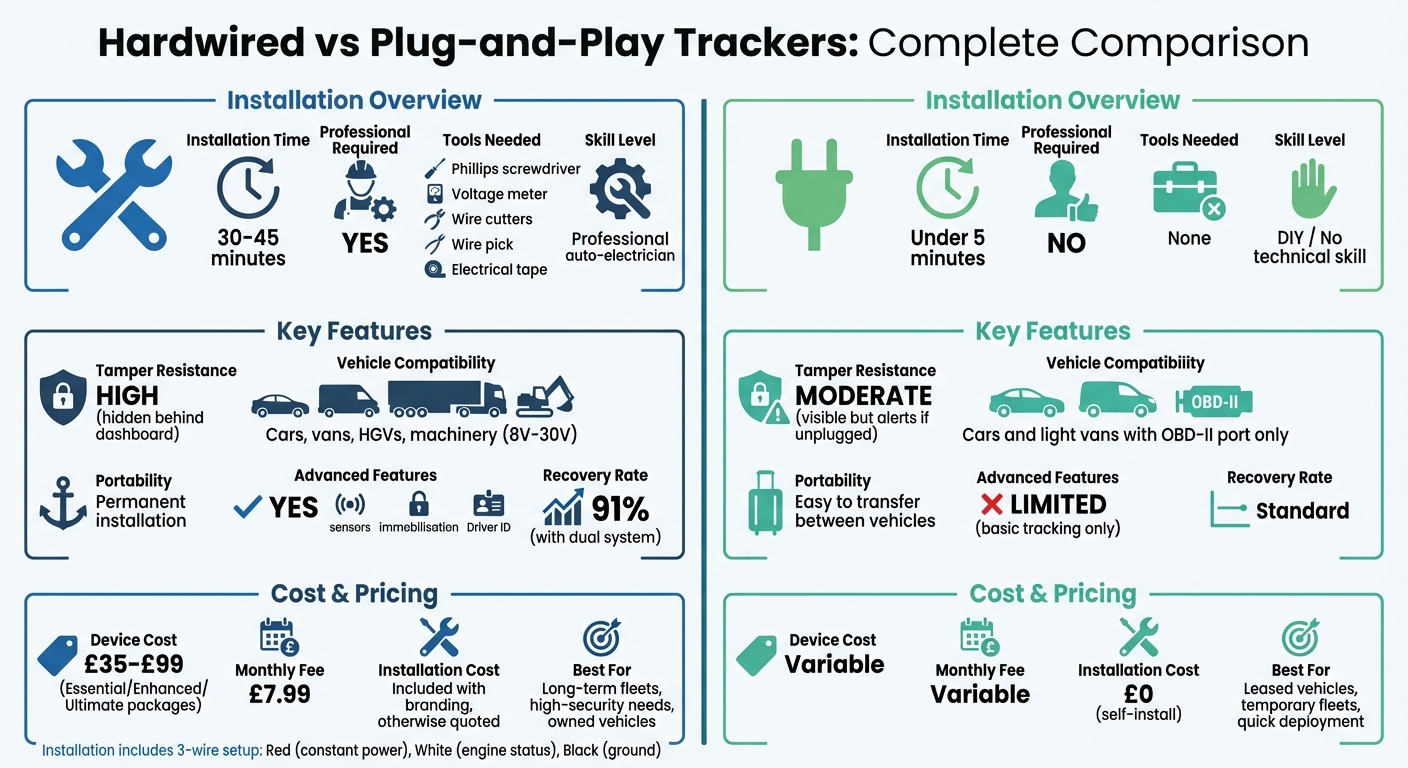

When choosing a van tracker, the installation method is just as important as the features. You have two main options:

- Hardwired Trackers: Installed permanently into the vehicle's electrical system by professionals. These are hidden for added security, support advanced features, and work with a wide range of vehicles, including HGVs and machinery. Installation takes about 30–45 minutes but requires downtime and professional help.

- Plug-and-Play Trackers: These connect to the OBD-II port and can be installed in under five minutes without tools or technical skills. They’re portable, ideal for leased or temporary vehicles, but more visible and easier to remove.

Quick Comparison

| Feature | Hardwired Tracker | Plug-and-Play Tracker |

|---|---|---|

| Installation Time | 30–45 minutes (requires scheduling) | Under 5 minutes |

| Tools/Skill Needed | Professional tools and expertise | None |

| Tamper Resistance | High (hidden behind dashboard) | Moderate (visible but alerts if unplugged) |

| Vehicle Compatibility | Cars, vans, HGVs, machinery | Cars and light vans with OBD-II |

| Flexibility | Permanent, vehicle-specific | Portable, easy to transfer |

| Advanced Features | Supports sensors, immobilisation | Limited to basic tracking |

Hardwired trackers are ideal for long-term fleets, high-security needs, and advanced monitoring. Plug-and-play trackers suit leased or temporary vehicles needing quick and simple tracking. Your choice depends on your fleet’s specific requirements.

Hardwired vs Plug-and-Play Vehicle Tracker Installation Comparison

How to: Install HIDDEN GPS Tracker for UNDER $50 (Sinotrack 4G Review)

What Are Hardwired Trackers?

Hardwired trackers are permanent telematics devices installed directly into a vehicle's electrical system. Unlike plug-and-play options, these trackers become a fixed part of the vehicle using a three-wire setup: red for constant power, white for engine status, and black for grounding.

To install one, the tracker is typically soldered or securely connected behind the dashboard near the ignition coil, keeping it hidden and resistant to tampering. Each unit is compact, measuring about 9cm × 5.5cm × 2.4cm and weighing just 90g. For the best performance, the GPS module should face upwards to maintain a strong satellite signal, as metal surfaces like steering columns can interfere with reception. This installation method not only ensures security but also enables additional monitoring features.

These trackers are highly versatile, making them ideal for fleet management. They operate within a voltage range of 8V to 30V, meaning they work with vehicles ranging from standard 12V cars and vans to 24V heavy goods vehicles, trucks, coaches, and even plant machinery. Beyond location tracking, they can integrate with various sensors via digital inputs. For example, fleet managers can monitor tailgate lifts, emergency door openings, warning lights, or even implement Driver ID systems. Despite their capabilities, these trackers consume very little power - similar to a vehicle clock - and include internal backup batteries. If the main power is disconnected or tampering occurs, the tracker sends immediate alerts.

What Are Plug-and-Play Trackers?

Plug-and-play trackers are small telematics devices that connect directly to a vehicle's OBD-II (On-Board Diagnostics) port. This port has been standard in all cars manufactured since 1996. Unlike hardwired systems that require a more complex three-wire setup, these devices simply plug into the OBD-II port, typically located under the driver’s side dashboard near the steering column. They draw both power and data directly from the vehicle’s computer system. The installation process is incredibly quick - usually under a minute. Fleet operators just plug the device in, scan a QR code to link it to their account, and tracking begins instantly. This ease of use makes them perfect for temporary or leased fleets.

What sets these trackers apart is their tool-free installation, which doesn’t require professional help. They provide real-time data, including vehicle location, driver behaviour (like speeding or harsh braking), and engine diagnostics straight from the vehicle’s system. However, their exposed position makes them easier to remove or tamper with. Additionally, they lack external ports needed for specialised sensors, such as those used to monitor snowploughs, lift gates, or temperature-controlled units.

Fleet operators often choose plug-and-play trackers for leased vehicles, seasonal fleets, or temporary contractors. Their non-permanent nature allows them to be moved between vehicles in seconds without causing wiring damage or violating lease agreements. If the device’s position interferes with driver comfort, an extension cable can be used to relocate it to a more discreet and safer spot.

How to Install Hardwired Trackers

Required Tools and Materials

To get started, you'll need the following tools: a Phillips head screwdriver, voltage meter, wire cutters, wire pick, ring terminal, electrical tape, and double-sided tape. These are essential for a smooth installation process.

On average, professional installers can complete a hardwired tracker installation in about 30 to 45 minutes per vehicle.

Installation Steps

-

Access the Dashboard

Begin by removing the dashboard panel beneath the steering wheel. Use a Phillips head screwdriver to carefully detach it. -

Identify Key Wires

With your voltage meter, locate these three wires:- Constant power wire: Should show a reading of 11 to 14 volts regardless of the ignition's position.

- Ignition wire: Reads 11 to 14 volts when the ignition is on and 0 volts when off.

- Ground point: A suitable metal surface to use as the ground connection.

-

Connect the Tracker Wires

- Attach the tracker's red wire to the constant power wire using the 'poke and wrap' method. Secure the connection with electrical tape.

- Repeat this method to connect the tracker's white wire to the ignition wire.

-

Ground the Black Wire

Fasten the black ground wire to a metal surface, like the steering column, using a ring terminal for a secure connection. -

Mount the Tracker Unit

Place the tracker behind the dashboard using double-sided tape. Ensure the tracker faces upwards to maintain strong GPS signal reception. Keep it away from large metal components, such as the steering column, to avoid signal interference. -

Reassemble the Dashboard

Once all connections are complete, reattach the dashboard panels.

Testing and Troubleshooting

After installation, start the engine. A blinking LED on the tracker confirms it is receiving power. Check the tracker’s live location through your tracking app to ensure it’s operational.

If the LED doesn’t light up, inspect the black ground wire to ensure it’s securely attached to a metal surface. Also, confirm the red power wire connection is firm. For GPS signal issues, double-check that the tracker is positioned correctly - facing upwards and not obstructed by the steering column or other metal parts. If the ignition status isn’t reporting properly, recheck the white wire’s connection to the ignition wire using the voltage meter.

It’s a good idea to run all these tests before fully reassembling the dashboard. This prevents the hassle of having to take it apart again later.

How to Install Plug-and-Play Trackers

Unlike hardwired systems, plug-and-play trackers are designed for quick and straightforward installation that you can manage on your own.

Tools and Materials You’ll Need

Plug-and-play trackers are made with convenience in mind, requiring only access to your vehicle's OBD-II port. This port, standard in most vehicles manufactured after 2000, provides both power and data connectivity. Your tracker package usually includes the tracking device itself and an instruction manual. Some kits might also come with extras like an OBD-II extension cable or adhesive strips for flexible mounting. Once you’ve got everything ready, follow these simple steps.

Step-by-Step Installation

-

Find the OBD-II Port:

Look under the dashboard near the steering column to locate the OBD-II port. If it’s not immediately visible, check the passenger footwell or inside the glove compartment. -

Connect the Tracker:

Push the tracker into the OBD-II port until you hear a click. This ensures a secure connection, preventing it from coming loose while driving. -

Power It On:

Start your vehicle’s engine to power the tracker and begin transmitting data.

The whole process takes only a few minutes. Once installed, it’s time to confirm everything is working correctly.

Testing and Troubleshooting

After starting the engine, check the tracker’s LED light. A blinking light indicates it’s powered and transmitting data. Next, open your tracking app to confirm your vehicle’s location is displayed.

If the LED doesn’t light up, unplug the tracker and reconnect it, ensuring it’s firmly in place. If the app doesn’t immediately show the vehicle’s location, wait a few minutes for the GPS signal to establish, then refresh the app.

For drivers who find the tracker’s positioning uncomfortable, use the included extension cable to adjust its placement.

Many trackers also feature tamper alerts, notifying you if the device is disconnected or if the vehicle moves while unplugged. Make sure your notification settings are active to take advantage of this added layer of security.

Installation Comparison: Hardwired vs Plug-and-Play

When deciding between hardwired and plug-and-play trackers, understanding the differences in installation is key. The table below breaks down the main factors, from time investment to security, to help you weigh your options.

| Feature | Hardwired Tracker | Plug-and-Play (OBDII) |

|---|---|---|

| Installation Time | 30–45 minutes | Under 5 minutes |

| Tools Needed | Phillips screwdriver, voltage meter, wire cutters, wire pick, electrical tape | None |

| Skill Level | Professional (Auto-electrician/Certified Installer) | DIY / No technical skill required |

| Vehicle Downtime | 30–60 minutes (requires scheduling) | Negligible (a matter of minutes) |

| Tamper Resistance | High (hidden behind the dash, soldered/hardwired) | Low to moderate (visible but sends alerts if unplugged) |

| Professional Help | Required for secure, permanent fit | Not required |

Hardwired Tracker Installation

Hardwired trackers demand a bit more effort upfront. Installation takes around 30–45 minutes and involves professional assistance from a certified auto-electrician. The device is integrated into the vehicle's electrical system and hidden behind the dashboard, making it difficult to detect or tamper with. This method ensures a secure and permanent fit, with the tracker soldered into place for added protection against theft or unauthorised removal.

Plug-and-Play Tracker Installation

Plug-and-play trackers, on the other hand, are all about simplicity. These devices can be installed in less than five minutes, with no tools or technical skills required. All you need to do is locate the OBDII port (usually beneath the dashboard) and insert the tracker until it clicks. Since there's no need for professional help, vehicle downtime is minimal, making this option particularly appealing for fleet operators. While these trackers are more visible, many modern models counteract this with tamper alerts, notifying you if the device is unplugged or the vehicle moves while disconnected.

Hardwired Installation: Advantages and Disadvantages

Hardwired trackers offer enhanced security and tamper resistance, setting them apart from plug-and-play alternatives. Since these devices are soldered directly into a vehicle's electrical system and concealed behind the dashboard, they are highly resistant to unauthorised interference. This makes them an ideal choice for fleets transporting high-value goods or operating in areas prone to theft. For instance, systems combining a primary hardwired tracker with a hidden backup have demonstrated a 91% success rate in recovering stolen vehicles.

Beyond basic location tracking, hardwired units provide advanced features tailored for fleet management. They can integrate with specialised equipment, such as tailgate lifts, emergency door sensors, and warning light switches. Additionally, they support technologies like Driver ID key fobs (e.g., iButton), allowing fleet managers to link specific trips to individual drivers in shared vehicles. This functionality not only helps distinguish between business and personal mileage but also enables detailed monitoring of driver behaviour.

A key advantage of hardwired trackers is their broad compatibility. Unlike plug-and-play devices, which are typically designed for cars and light vans with OBDII ports, hardwired trackers can be installed in a wide range of vehicles, including HGVs, trucks, and heavy machinery. They also operate across a wide voltage range (usually 8V to 30V), making them suitable for both 12V and 24V systems without requiring modifications. However, these benefits come with certain limitations.

One drawback is the need for professional installation, which requires a trained engineer and scheduled vehicle downtime. This makes transferring a hardwired tracker between vehicles a more complex process, often necessitating another engineer visit. As a result, these devices may not be the best fit for fleets with short-term leases or frequently changing vehicles.

Cost is another consideration. While GRS Fleet Telematics offers hardwired trackers starting at £35, installation fees vary and are usually quoted individually. DIY installation is challenging without mechanical expertise, as it requires specific tools and carries the risk of damaging the vehicle's electrical system if wiring is done incorrectly. Additionally, the tracker must be carefully placed away from metal surfaces, as GPS signals cannot penetrate through metal.

Plug-and-Play Installation: Advantages and Disadvantages

Plug-and-play trackers are all about speed and convenience, which makes them a go-to option for businesses managing leased vehicles or temporary contractors. The installation process is incredibly quick - just a matter of minutes. This eliminates the need to book an engineer, keeping vehicles operational with almost no downtime.

One of their standout features is portability. These devices are easy to move between vehicles. If a vehicle is replaced or returned, you can simply unplug the tracker, plug it into the new vehicle, and update the software to continue tracking. This flexibility is especially useful for businesses that can’t make permanent changes to vehicles they don’t own.

However, there are some trade-offs. Since these trackers connect to the OBD port, they’re relatively easy to find and remove. While many modern models have tamper alerts that activate if the device is unplugged, they still lack the discreetness of hardwired trackers, which are hidden behind the dashboard. This makes them more vulnerable to theft, particularly in high-risk situations.

Compatibility can also be an issue. Unlike hardwired trackers, which work with a wide range of vehicles, plug-and-play devices are generally limited to cars and light vans. They also miss out on advanced features like driver ID key fobs, remote immobilisation, and specialised sensors. For fleets requiring these advanced monitoring capabilities or needing to cover a variety of vehicle types, hardwired trackers remain the better option.

GRS Fleet Telematics Installation Options

After outlining the installation process, GRS Fleet Telematics introduces its customised hardwired tracker packages.

There are three tracker packages available, designed to suit various security requirements and budgets. Each tracker is installed by professionals - usually within 30 to 40 minutes - and discreetly placed under the dashboard, connected directly to the vehicle's power and ignition systems. Installation is included at no extra cost if GRS Fleet Graphics branding is used; otherwise, pricing details are available on request.

These trackers are compatible with cars, vans, and HGVs and come with a monthly service fee of £7.99.

Essential Tracker (£35) Installation

The Essential Tracker provides a budget-friendly option with a single hardwired GPS unit. It delivers dependable real-time location tracking, making it a practical choice for businesses.

Enhanced Tracker (£79) Installation

The Enhanced Tracker includes a dual-tracker system, combining a primary hardwired GPS tracker with a secondary Bluetooth backup device. The primary tracker is securely installed, while the Bluetooth backup is discreetly hidden. If the primary tracker is disabled, the backup device ensures location data continues to transmit. This system has contributed to a 91% recovery rate for stolen vehicles within 24 hours.

Ultimate Tracker (£99) Installation

The Ultimate Tracker builds on the Enhanced package by adding an immobilisation circuit. During installation, this circuit is connected to the vehicle’s engine management system, allowing fleet managers to remotely stop the engine from starting. This feature can be triggered manually or automatically in response to unauthorised movement alerts, offering top-level security for high-value vehicles or those operating in areas with higher theft risks.

These packages give fleet managers the flexibility to choose a solution that aligns with their security needs and operational goals.

Choosing the Right Installation Method for Your Fleet

Deciding on the best installation method for your tracking devices is crucial for keeping your fleet running smoothly. The choice between hardwired and plug-and-play trackers depends on factors like fleet ownership, operational needs, and security priorities. If you own your vehicles long-term and operate in areas prone to theft, hardwired trackers are the better option. These devices are tucked away behind the dashboard with soldered connections, making them much harder to find or tamper with. On the other hand, for leased or short-term vehicles, plug-and-play devices offer flexibility, allowing you to easily transfer trackers between vehicles without needing professional help.

The size of your fleet and how much downtime you can tolerate also play a role in this decision. Smaller fleets often prefer self-installation to avoid the hassle of scheduling engineers and to get tracking up and running immediately. Larger fleets, however, usually lean towards professional installation to ensure uniformity across all vehicles. If downtime during peak hours is a concern, plug-and-play devices can be installed in under five minutes during driver breaks, minimising disruption.

For advanced features like driver identification, remote immobilisation, or alerts for specialised equipment, hardwired systems are essential, as plug-and-play devices don’t support these capabilities. However, if your needs are limited to basic GPS tracking and trip reporting, OBD units work well, provided your vehicles have accessible OBDII ports.

Cost and return on investment (ROI) are also key considerations. While hardwired systems have a higher initial cost, they can pay for themselves within 90 days, saving £1,000–£2,000 per vehicle annually. For high-value assets, using dual-tracking systems increases recovery rates, as shown by GRS Fleet Telematics' impressive 91% success rate in asset recovery.

FAQs

What are the key benefits of hardwired trackers compared to plug-and-play trackers?

Hardwired trackers bring distinct advantages over plug-and-play options, especially when it comes to security, reliability, and advanced functionality. These systems are installed by a professional engineer, connecting them directly to your vehicle’s electrical system. This integration not only makes them discreet and resistant to tampering but also ensures they stay securely in place, offering a dependable and robust solution.

Thanks to their hardwired nature, these trackers provide features like tamper alerts, driver identification, impact detection, and a constant power supply, ensuring they function without interruptions. While plug-and-play trackers are easier to install and can be moved between vehicles, they don’t offer the same level of permanence or security. For long-term fleet management and heightened vehicle protection, hardwired systems are often the superior choice.

What impact does the installation of hardwired trackers have on fleet operations?

Installing hardwired trackers can cause some short-term disruptions to fleet operations. This is because the process involves vehicle downtime and professional installation. These devices are connected directly to the vehicle’s electrical system, which typically takes about 30–40 minutes per vehicle and must be carried out by a trained engineer. For fleets with multiple vehicles, this can temporarily impact operations.

That said, the long-term advantages often make the initial hassle worthwhile. Hardwired trackers offer a secure, tamper-resistant solution that delivers precise data, boosting fleet security and improving management efficiency. While the installation requires careful planning, the dependability and advanced capabilities of these systems make them a smart choice for businesses overseeing large vehicle fleets.

Are plug-and-play trackers compatible with all vehicles?

Yes, plug-and-play trackers can be used with a wide range of vehicles, including cars, vans, lorries, and even plant machinery. These devices are designed to connect directly to the vehicle's onboard diagnostic (OBD) port and are compatible with standard 12V or 24V batteries.

Their ease of use makes them a great choice for anyone seeking a straightforward installation process. There's no need for professional fitting, which saves time and effort.