Fleet Load Balancing with Battery Storage

Manage EV fleet charging with on-site battery storage and telematics to shave peaks, cut energy costs and avoid costly grid upgrades.

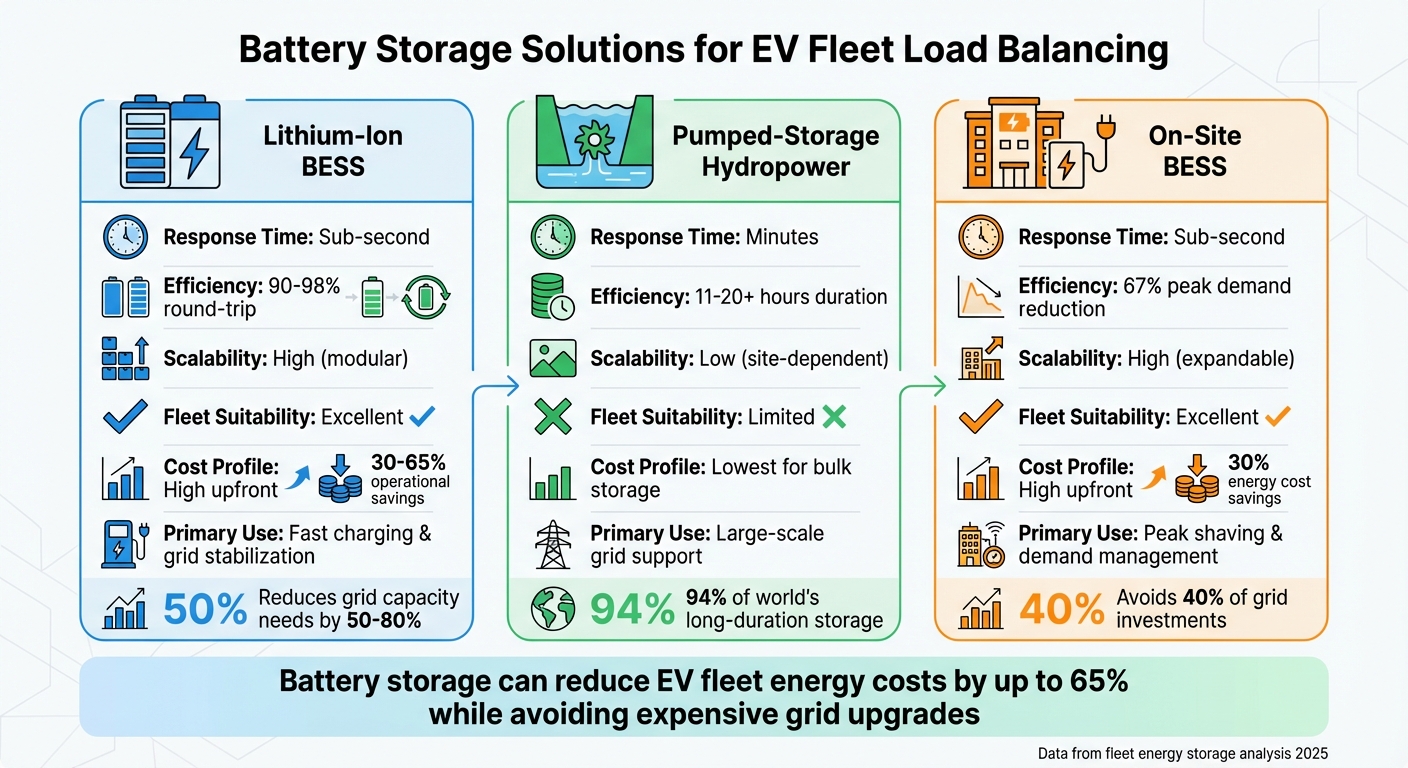

Managing EV fleet charging while avoiding grid overload is challenging, especially with fluctuating renewable energy supplies. Battery storage solutions, like lithium-ion systems, offer a way to distribute power efficiently, reduce costs, and minimise the need for expensive grid upgrades.

Here’s what you need to know:

- Lithium-ion batteries: Highly efficient (90–98%), modular, and ideal for fast response to demand spikes. They also reduce energy costs by up to 65% but come with high upfront costs.

- Pumped-storage hydropower (PSH): Best for large-scale grid support, providing long-duration energy storage. However, it’s unsuitable for fleet depots due to site limitations and slow activation times.

- On-site battery storage: Helps depots manage peak demand, cut costs, and avoid grid upgrades. Modular design allows scaling as fleets grow.

- Telematics integration: Adds real-time control, optimising charging schedules and reducing electricity expenses further.

Quick Comparison:

| Feature | Lithium-Ion BESS | Pumped-Storage Hydropower | On-Site BESS |

|---|---|---|---|

| Response Time | Sub-second | Minutes | Sub-second |

| Scalability | High (modular) | Limited (site-dependent) | High (expandable) |

| Fleet Suitability | High | Low | High |

| Cost Profile | High upfront | Lower for bulk storage | High upfront, savings |

Fleet operators can combine battery storage with telematics to improve energy efficiency, reduce costs, and support EV transitions.

Battery Storage Solutions Comparison for EV Fleet Operations

SCU Energy Storage and Charging Solution for Electric Vehicle Fleet Charging for Netherland customer

1. Lithium-Ion Battery Storage

Lithium-ion batteries, particularly the Lithium Iron Phosphate (LiFePO4) type, have become a top choice for fleet operators managing renewable energy loads. These batteries offer an impressive round-trip efficiency of 90% to 98%, meaning almost all the energy stored during charging is available for use later. In contrast, traditional lead-acid batteries only achieve 70% to 85%, showcasing the efficiency gap between the two technologies.

Efficiency

Lithium-ion batteries boast a Coulombic efficiency of over 99%, while lead-acid batteries average around 90%. Bob Wu, a Solar Engineer at Anern, highlights the importance of this efficiency:

A battery with low round trip efficiency effectively wastes a portion of the solar energy you've generated... Over the lifetime of the system, this can amount to a significant loss of energy and financial savings.

For fleet depots relying on unpredictable solar energy, this efficiency ensures more power is available when vehicles need charging.

Another advantage is their rapid response to sudden demand spikes, such as when multiple vehicles start charging at once. Oren Halevi, Chief Product Officer at Driivz, explains:

Batteries deliver a much faster load demand response than the gradual ramp-up times that conventional thermal plants require, making them ideal 'peaker' plants capable of meeting the dynamic energy needs of the grid and the charging site.

Additionally, battery-buffered systems can reduce the power grid capacity needed for charging stations by 50% to 80%, further demonstrating their role in efficient energy management.

Scalability

Lithium-ion systems are modular, making them suitable for installations ranging from small-scale setups to massive gigawatt-hour projects. This flexibility allows fleet operators to expand their energy storage as their charging needs grow. With smart energy management, sites can increase EV charging capacity by up to six times without upgrading the existing electrical infrastructure.

Cost-Effectiveness

The average cost of lithium-ion batteries is approximately £890 per kWh (around $1,151 USD). While the upfront investment can be significant, the long-term benefits outweigh the costs. LiFePO4 batteries can handle over 5,000 charge-discharge cycles at 80% depth-of-discharge, whereas lead-acid batteries may start to degrade after just 500 cycles.

| Feature | Lithium-Ion (LiFePO4) | Lead-Acid Battery |

|---|---|---|

| Round-Trip Efficiency | 90%–98% | 70%–85% |

| Cycle Life (at 80% DoD) | 2,000–5,000+ | 300–700 |

| Energy Density | 150–220 Wh/kg | 30–40 Wh/kg |

| Maintenance | Minimal/None | Regular |

Suitability for Fleet Operations

Lithium-ion batteries are ideal for opportunity charging, enabling vehicles to recharge during short breaks and maximising fleet uptime. Their higher energy density (150–220 Wh/kg) also saves valuable floor space compared to lead-acid batteries, which only offer 30–40 Wh/kg. For optimal performance, these batteries should operate within a temperature range of 15°C to 35°C and maintain a charge state between 10% and 90%. This combination of efficiency, compact design, and durability makes lithium-ion batteries an essential tool for managing fleet energy demands effectively.

2. Pumped-Storage Hydropower

Pumped-storage hydropower (PSH) plays a pivotal role as a large-scale energy storage system, capturing surplus renewable energy and releasing it during peak demand. With the UK's push towards net-zero targets, PSH has gained renewed attention for its ability to stabilise the grid and support renewable energy integration. According to the International Hydropower Association:

PSH is the largest long-duration energy storage technology... this accounts for over 94% of the world's long duration energy storage capacity, well ahead of lithium-ion and other battery types.

Efficiency

When it comes to long-duration energy storage, PSH stands out. It can operate continuously for extended periods, ranging from 11 to over 20 hours. A prime example is the Loch Earba project in Scotland, approved in April 2025, which will deliver 22 hours of storage at full power with a capacity of 1.8 GW and 40,000 MWh of storage. This capability makes PSH invaluable during prolonged dips in renewable energy generation, ensuring grid stability. For fleet operators, this translates to more predictable electricity prices and reliable power for overnight charging.

Scalability

Globally, PSH has achieved significant scale, with nearly 200 GW of installed capacity and 9,000 GWh of electricity stored. However, the technology requires two reservoirs at different elevations, which limits site availability. While this makes it a utility-scale solution rather than one for individual deployment, research has identified around 600,000 potential off-river sites worldwide, indicating room for expansion.

Cost-Effectiveness

PSH projects come with high upfront costs and lengthy construction timelines, often exceeding five years. To encourage investment, the UK government and Ofgem introduced a "cap and floor" mechanism in 2025, providing revenue certainty for such projects. Carl Crompton, Managing Director at Gilkes Energy, highlights the broader benefits:

The Earba project... addresses decarbonisation, energy security, and cost reduction.

By reducing wind curtailment costs - expenses that would otherwise be passed on to consumers - PSH helps lower overall electricity system costs. Additionally, these projects have a lifespan of over 50 years and avoid reliance on costly materials like lithium or cobalt.

Suitability for Fleet Operations

While PSH isn't something fleet depots can implement on their own, it plays a critical role in supporting the national grid. This, in turn, benefits fleet managers by improving the availability and affordability of renewable energy during overnight charging windows. Large-scale projects like Coire Glas and Loch Earba will influence charging schedules by ensuring more stable and "green" energy supply. The next section will delve into on-site battery storage solutions, which complement the grid-level benefits of PSH by offering localised energy management options.

3. On-Site Battery Storage

On-site battery storage offers fleet depots the ability to capture renewable energy on-site and use it during peak demand periods. Unlike larger grid-scale systems like pumped-storage hydropower, these solutions put energy management directly in the hands of fleet managers. This control is especially helpful for locations with limited electrical capacity, as it allows power to be distributed across charging points without overloading circuits or requiring costly grid upgrades.

Efficiency

Battery Energy Storage Systems (BESS) are highly effective for peak shaving - a process that reduces the highest levels of power demand from the grid by as much as 67%. They charge during off-peak hours when electricity is cheaper and discharge quickly during periods of high demand. When combined with dynamic load management, BESS can further optimise energy use by tapping into lower site loads for additional savings. In the UK, some fleet operators have reported cutting energy costs by up to 30% through peak shaving techniques.

Scalability

One of the most appealing features of BESS is their modular design, which allows fleet operators to scale up storage capacity as their electric vehicle (EV) fleets expand. Instead of investing in an oversized system from the start, operators can add capacity incrementally. For instance, in 2024, Dundee City Council and Volvo Trucks UK & Ireland both implemented modular BESS solutions to support high-powered charging and improve operational resilience. This approach not only ensures flexibility but also provides a clearer picture of overall system costs over time.

Cost-Effectiveness

The cost of implementing BESS includes both equipment and installation expenses. Equipment alone makes up 50–60% of the total investment, with the rest covering labour, planning, and electrical work. Battery prices vary widely, ranging from around £480/kWh to over £1,100/kWh depending on the type and brand. On-site storage can help fleet operators avoid or delay costly Distribution Network Operator (DNO) upgrades, which can run into hundreds of thousands of pounds and take years to complete. Installing a battery alongside a new solar PV system can also save money, as shared labour and wiring reduce overall costs compared to retrofitting later.

Suitability for Fleet Operations

On-site battery storage addresses several challenges faced by fleet operators. It can cut electricity costs by up to 65% through smarter charging strategies, defer or eliminate up to 40% of grid-related investments, and ensure operations continue even during power outages. Michael Phelan, CEO of GridBeyond, emphasises the broader benefits:

"Grid infrastructure constraints are now one of the biggest barriers to EV fleet rollouts in the UK. Battery solutions, combined with smart charging and flexibility services, can not only solve these challenges but also deliver long-term operational and financial benefits."

For fleet depots, choosing the right battery chemistry is key. Lithium-iron phosphate (LFP) batteries are often a better fit than Nickel Manganese Cobalt (NMC) alternatives, as they offer longer lifespans, enhanced safety, and better efficiency for frequent charging cycles - making them ideal for daily operations. When integrated with telematics, battery storage systems can further optimise energy management across the fleet.

4. Battery Storage with Telematics

Telematics takes battery storage to the next level by turning it into a smart system that reacts in real time to the demands of a fleet. Fleet operators can fine-tune charging priorities based on what’s needed at the moment - whether it’s a quick charge during a shift or a slower, overnight recharge. This smart integration enhances earlier battery storage methods by adding real-time flexibility. It means depots can handle more charge points or use higher-powered chargers without overloading their electrical capacity. Essentially, telematics brings a layer of intelligent control to fleet energy management.

Efficiency

Dynamic load management systems are the backbone of this efficiency. They constantly monitor energy usage across the site and ensure power is distributed effectively to all active charge points. Spare capacity is redirected to where it’s needed most. With advanced remote control features, operators can adjust and prioritise charging sessions on the fly, ensuring the system operates smoothly and efficiently.

Cost-Effectiveness

Telematics-based systems help cut costs by sidestepping expensive Distribution Network Operator (DNO) upgrades. For instance, using Vehicle-to-Grid (V2G) technology, coordinated via telematics, can save up to £12,000 annually per electric vehicle. On a broader scale, the UK government projects that battery storage could save the energy system as much as £40 billion by 2050. Operators can also track vehicle usage through apps or RFID cards, allowing them to optimise charging schedules and driver performance.

Scalability

Adopting data-driven systems early on helps fleets grow without breaking the bank on infrastructure upgrades. These systems make the most of existing grid connections, delaying the need for costly capacity expansions. Between 2020 and 2025, the UK saw a staggering 509% increase in operational battery storage capacity. Fleet operators can also tap into revenue opportunities, such as frequency response and wholesale energy trading, to offset costs as they scale up.

Suitability for Fleet Operations

Telematics is a perfect fit for fleet operations. With predictable schedules and real-time data, fleets can precisely coordinate charging cycles to keep things running smoothly. This level of control also makes it easier to participate in demand response programmes, which offer financial rewards for cutting electricity usage during peak times. For depots with varied shift patterns and high-duty cycles, continuous monitoring and data integration ensure efficient operations. Plus, this approach supports the use of renewable energy sources, tying back to the broader benefits outlined in the Introduction.

Advantages and Disadvantages of Each Storage Solution

Here’s a breakdown of the key features, benefits, and limitations of the storage solutions we’ve discussed. Each option has its own strengths and trade-offs, tailored to different operational needs.

Lithium-ion battery storage stands out with its lightning-fast response times, making it perfect for handling sudden power surges, such as when multiple electric vehicles charge at once. While the upfront costs are steep, production costs are dropping, and operators can achieve operational savings between 30–65%. However, its primary role lies in fast charging and grid stabilisation.

Pumped-storage hydropower shines in large-scale grid applications, offering the lowest capital costs for bulk energy storage. It plays a steady role in contributing to Britain’s zero-carbon energy goals, providing 3% of the country’s electricity during winter months. That said, it’s not a practical option for individual fleet sites. It’s highly dependent on specific geological conditions, experiences standby energy losses, and has slower activation times compared to battery systems.

For localised control, on-site battery storage is a game-changer. It can reduce depot peak demand by up to 67%, and UK fleet operators have reported energy cost savings of up to 30% using this approach. Its modular design makes it easy to scale as fleets grow, and it can defer or eliminate up to 40% of grid investments tied to EV charging infrastructure. This translates to significant reductions in demand charges.

The table below compares how these solutions stack up across critical operational factors:

| Feature | Lithium-Ion BESS | Pumped-Storage Hydropower | On-Site BESS |

|---|---|---|---|

| Response Time | Sub-second | Minutes (slower activation) | Sub-second (immediate peak shaving) |

| Scalability | High (modular) | Low (geography-dependent) | High (expandable modules) |

| Fleet Suitability | Excellent | Limited | Excellent |

| Cost Profile | High upfront; declining production costs | Lowest for large-scale | High upfront; 30–65% operational savings |

| Primary Application | Fast charging and grid stabilisation | Bulk energy shifting | Peak shaving and demand management |

Conclusion

Battery Energy Storage Systems (BESS) offer fleet operators a fast and adaptable solution, standing in contrast to pumped-storage hydropower, which requires specific geological conditions and extensive construction timelines. Thanks to their modular design, BESS allows operators to start small and expand as their fleets grow, while also reacting within milliseconds to sudden power surges.

With battery pack prices expected to drop to around £65/kWh by 2030, the case for adopting BESS becomes increasingly compelling. One of the key challenges to widespread EV adoption remains grid infrastructure limitations. However, as Michael Phelan, CEO of GridBeyond, highlights:

Battery solutions, combined with smart charging and flexibility services, can not only solve these challenges but also deliver long-term operational and financial benefits.

The integration of battery storage with telematics platforms takes operational control to the next level. This combination allows for optimised charging schedules, potentially reducing electricity costs by up to 65%. At the same time, it provides fleet managers with real-time data on battery health, state of charge, and vehicle usage patterns - essential for extending asset life and improving efficiency.

To make the most of these advancements, fleet operators can take several practical steps. Conducting a telematics-based load audit ensures the battery system is sized correctly. Deploying modular BESS integrated with energy management systems and using smart tariffs to charge during off-peak hours can significantly cut costs. Early engagement with Distribution Network Operators and opting for systems that support future Vehicle-to-Grid capabilities can help avoid delays and unlock additional revenue streams.

For example, GRS Fleet Telematics offers essential tools for real-time tracking and energy monitoring. With comprehensive vehicle data and driver behaviour analytics available from just £7.99 per month, operators can make smarter decisions about charging schedules, battery maintenance, and energy usage - turning the transition to electric vehicles into a strategic advantage.

FAQs

What are the differences between lithium-ion and lead-acid batteries for fleet energy storage?

Lithium-ion batteries outperform lead-acid batteries in both efficiency and durability, making them a superior option for fleet energy storage. With their higher energy density, they support longer operating times and hold up well under high discharge rates. This reliability makes them an excellent fit for fleets that depend on steady and consistent power.

While lead-acid batteries may cost less initially, they typically have shorter lifespans and struggle with efficiency under demanding conditions. In the long run, the reduced maintenance needs and extended lifespan of lithium-ion batteries often prove to be the more economical choice for fleet operations.

How does integrating telematics with on-site battery storage benefit fleet management?

Integrating telematics with on-site battery storage offers a smart solution for fleet management, particularly when it comes to making better use of renewable energy. Telematics delivers real-time insights into vehicle operations, enabling fleets to fine-tune charging schedules and manage energy consumption more effectively. When combined with on-site battery storage, this system allows vehicles to charge during periods of surplus renewable energy or when electricity demand is low. The result? Lower costs and reduced strain on the power grid.

This combination also boosts operational reliability while cutting expenses. By analysing data on vehicle usage and energy needs, fleets can plan charging during off-peak hours, saving on energy costs and extending battery lifespan with controlled charging cycles. Beyond cost and efficiency, this approach aligns with renewable energy goals and supports the UK's push towards achieving net-zero emissions.

Why isn’t pumped-storage hydropower practical for fleet depots?

Pumped-storage hydropower doesn't work well for fleet depots because it demands substantial infrastructure and specific geographical conditions, like steep elevation changes and large amounts of land. These requirements are rarely found at typical fleet depot sites.

On top of that, the sheer size and expense of these systems make them impractical for on-site energy storage. Instead, smaller and more adaptable options, such as battery storage systems, are far better suited for these localised needs.