AI Route Optimisation for Construction Fleets

AI route optimisation is revolutionising construction fleet management by improving efficiency, cutting costs, and reducing environmental impact.

AI-powered route optimisation is transforming fleet management, especially for construction companies facing unique challenges like temporary sites, shifting schedules, and weight restrictions. Here's what you need to know:

- Time Savings: AI can cut delivery times by 15–30%.

- Cost Reductions: Fuel consumption drops by 10–15%, and overall fleet costs decrease by up to 30%.

- Environmental Impact: Emissions can be reduced by 15–20% through optimised routes and efficient vehicle use.

- Adaptability: AI recalculates routes in real-time, handling unpredictable factors like weather, traffic, and site accessibility.

- Vehicle-Specific Planning: Accounts for weight limits, load capacities, and delivery schedules.

Construction fleets, unlike logistics or retail, must navigate complex, changing environments. AI systems solve these problems by optimising routes, improving efficiency, and reducing costs. Whether you're dealing with rising fuel prices, driver shortages, or stricter delivery regulations, AI is proving to be a game-changer for the construction sector.

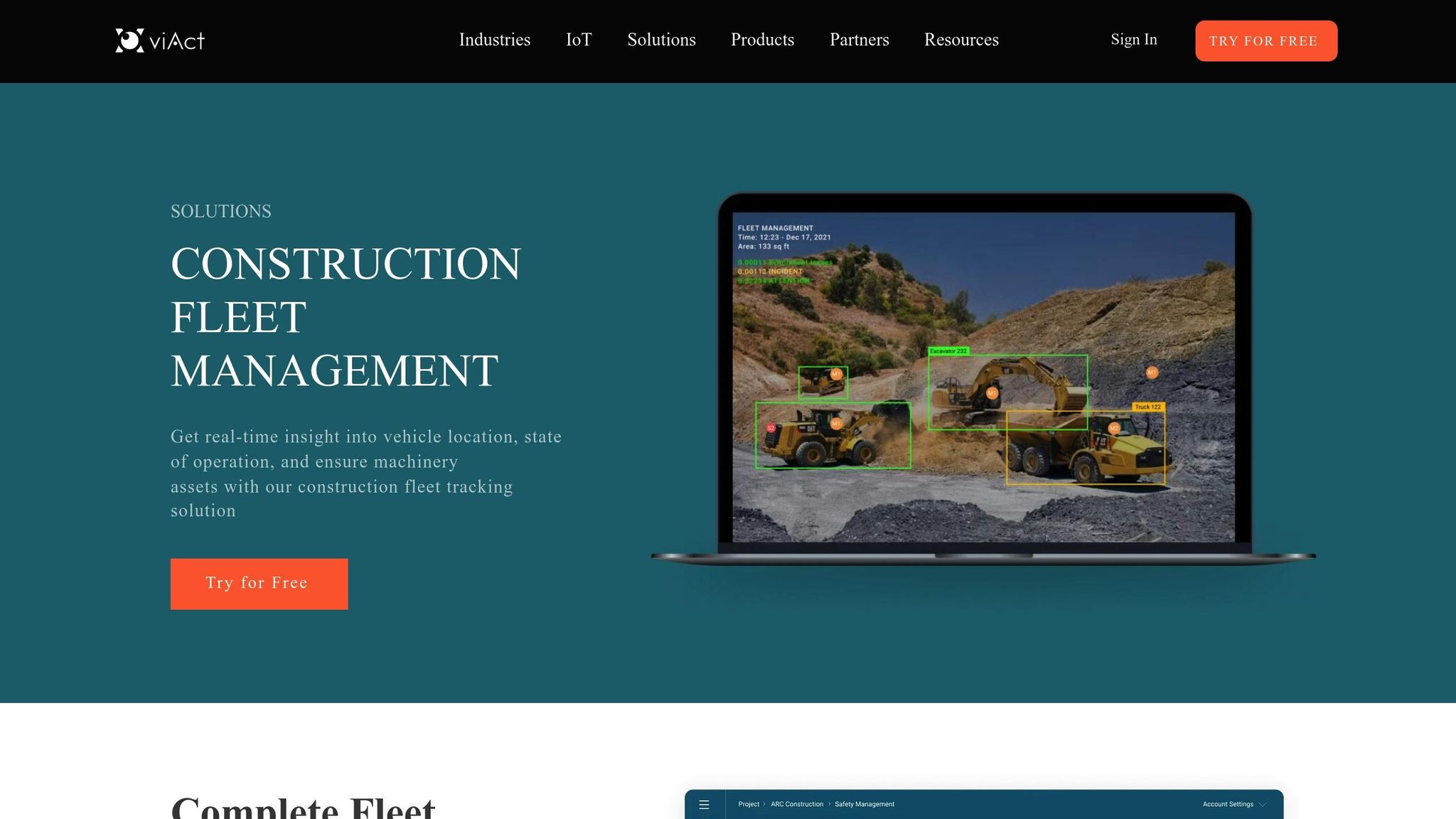

AI-powered Construction Fleet Management System : viAct

1. Construction Fleet Route Optimisation

Construction fleets operate in an environment filled with unique challenges, making traditional route planning tools insufficient. To navigate these complexities, AI-powered route optimisation systems are essential. They handle multiple variables, adapt to shifting conditions on-site, and offer solutions tailored to the unpredictable nature of construction operations.

Operational Complexity

Unlike standard delivery routes, construction operations come with a host of challenges. Construction sites often lack precise postcodes, rely on temporary access roads, and involve coordinating deliveries with subcontractors working on tight schedules. These factors make route planning far more intricate.

AI systems excel here by recalculating routes in real time. They account for unpredictable factors such as changing road conditions, weather disruptions, and fluctuating demand. By processing data like traffic patterns, site accessibility, and delivery windows, these systems ensure that construction fleets can navigate the volatile landscape of site deliveries effectively.

Route Predictability

Construction sites, by their nature, require flexibility. Unlike fixed delivery locations, these sites often shift, and access needs can change rapidly. Traditional systems, which depend on historical data, struggle to accommodate such variability.

AI-driven route optimisation steps in to bridge this gap. It adapts to new locations and evolving requirements, streamlining delivery processes. This not only helps construction businesses meet growing customer demands but also cuts operational expenses. In fact, fleets using AI-powered systems report cost reductions of up to 15%.

Vehicle Constraints

A construction fleet typically includes a wide range of vehicles, each with specific capacities, dimensions, and weight limits. From concrete mixers to flatbed lorries, every vehicle has unique needs that must be factored into route planning. For instance, routes must account for restrictions like bridge weight limits, low clearances, toll roads, and local heavy vehicle regulations.

AI systems handle these variables seamlessly. They incorporate vehicle-specific details - such as load capacities and delivery timeframes - into their calculations. Additionally, they optimise how vehicles are loaded, ensuring efficient sequencing of deliveries and balanced weight distribution. This not only improves fuel efficiency but also enhances overall fleet performance.

Environmental Impact

Reducing the environmental impact of construction fleets has become a critical priority. With the transportation sector responsible for roughly 25% of global CO₂ emissions, optimised routing offers a clear path to improvement. AI systems can cut time spent on the road by up to 20%, significantly lowering emissions. They also minimise idling and promote efficient vehicle use, further reducing the carbon footprint.

For companies aiming to operate more sustainably, AI-powered route optimisation delivers immediate results. By integrating logistics software, fleets can lower emissions by as much as 15%. Tools like GRS Fleet Telematics complement these systems by providing eco-driving analytics, enabling managers to monitor and improve driver behaviour. Together, these technologies enhance efficiency while supporting environmental goals.

2. Logistics Fleet Route Optimisation

The logistics sector operates within a unique framework, distinct from construction fleets. While delivery patterns in logistics are often more predictable, the industry faces its own set of challenges that require advanced technological solutions to stay efficient and competitive.

Operational Complexity

Logistics operations have become increasingly intricate due to global supply chains, the rapid growth of e-commerce, and rising customer demands for faster delivery times. For instance, 64% of customers expect delivery within two days, and 25% are willing to pay extra for same-day service. Unlike construction fleets, which deal with site-specific access issues, logistics fleets must juggle multiple delivery schedules, work with distribution centres, and cater to various customer needs. AI solutions play a key role here, cutting delivery times by 30–40% and improving on-time delivery rates from 75% to an impressive 95%.

Route Predictability

While logistics fleets benefit from fixed customer locations, the sheer volume of deliveries introduces new hurdles. Last-mile delivery alone accounts for 50–60% of total delivery costs, making it a critical area for optimisation. AI systems address this by using predictive analytics to forecast demand and plan routes in advance. This approach has resulted in a 30% improvement in delivery accuracy. At the same time, these systems provide the flexibility needed to manage urgent deliveries, returns, and service calls, balancing efficiency with adaptability.

Vehicle Constraints

Logistics fleets include a wide variety of vehicles, from compact vans to large lorries, each with its own capacity and operational challenges. Urban areas add further complications, such as weight and height restrictions and congestion zones. AI algorithms help optimise vehicle loads, delivery schedules, and routes, taking into account factors like time windows, road limitations, and fuel efficiency. This has led to tangible savings - companies have reduced delivery costs by 15% through smarter load planning. A standout example is UPS, which saves approximately £320 million annually with its AI-driven Orion system. The system improves delivery sequences by factoring in vehicle-specific constraints, demonstrating the financial and operational advantages of such technology.

Environmental Impact

Urban deliveries come with a significant environmental footprint, making sustainability a priority for logistics fleets. AI-powered systems can cut CO₂ emissions by 15–20% and deliver fuel savings of 20–25% compared to traditional methods. By optimising routes, these systems eliminate unnecessary mileage and reduce idle time, slashing delivery costs by up to 30% through better fuel efficiency and fleet utilisation.

In the UK, combining AI with tracking tools like GRS Fleet Telematics enhances efficiency further, bolstering asset security and ensuring compliance with regulations. These advancements not only reduce costs but also contribute to a greener, more sustainable logistics industry.

3. Retail Fleet Route Optimisation

Retail fleets operate under unique pressures, juggling multi-stop deliveries and tight schedules. Unlike construction or logistics fleets, retail deliveries require even greater flexibility due to the diverse nature of customer needs.

Operational Complexity

Retail fleet operations are a logistical puzzle, balancing short delivery windows with multiple stops in different locations. AI and machine learning step in to predict traffic patterns and make real-time route adjustments, ensuring timely and efficient deliveries.

The challenge lies in optimising the entire fleet, not just individual vehicles. Traditional methods often focus narrowly on cutting travel time and fuel costs, overlooking broader considerations like fleet-wide resource allocation and availability.

The combination of GPS, telematics, big data, analytics, and AI has revolutionised how retail fleets manage their routes. This technological leap is paving the way for even greater advancements in predictability and vehicle management.

Route Predictability

AI systems continuously process historical data, live traffic updates, and weather conditions to create more accurate, flexible routes. As Campbell Smith, an account executive at PTV Group, puts it:

"When you plan something, the focus is on how do I, as a company, benefit from delivering something to somebody at a certain time. When you optimise it, the focus changes to the needs of the customer. When can I deliver it to him/her to better improve customer satisfaction?"

This focus on predictability not only improves resource management but also ensures that retail fleets meet the tight delivery windows customers expect.

Vehicle Constraints

Retail fleets are made up of a mix of vehicles, from small vans to large lorries, each with its own limitations. AI algorithms incorporate real-time data on road conditions, traffic, and regulations to optimise vehicle use.

Tracking tools like GRS Fleet Telematics provide real-time visibility into fleet operations. This allows managers to make informed decisions about vehicle deployment and route adjustments, which is critical in a sector where reliability and timing are non-negotiable.

Environmental Impact

AI-driven route optimisation doesn’t just improve efficiency - it also supports sustainability. These systems account for factors like distance, traffic, and road conditions to find the most fuel-efficient routes. They can even optimise vehicle loading to reduce fuel consumption.

Retail fleets using AI have reported significant reductions in fuel usage and emissions. For example, one last-mile delivery service achieved over a 10% cut in miles driven by implementing AI-based routing. Real-time adjustments based on traffic, weather, and vehicle performance further enhance these benefits.

As environmental awareness grows, the market for route optimisation software is expected to expand, with a projected CAGR of 13.90% by 2030. AI also helps fleets transition to greener alternatives by identifying opportunities to incorporate electric or hybrid vehicles. Overall, optimising fleet operations - including routes - can cut costs by up to 30% while aligning with sustainability goals.

Advantages and Disadvantages

AI-driven routing brings both opportunities and challenges to the construction, logistics, and retail sectors. By tailoring static and dynamic routing strategies to their specific needs, these industries can optimise operations while addressing sector-specific demands. Here's a closer look at how each sector leverages routing strategies:

| Factor | Construction Fleets | Logistics Fleets | Retail Fleets |

|---|---|---|---|

| Route Predictability | Advantage: Static routing works well for recurring site visits and scheduled tasks. | Advantage: A mix of static and dynamic routing balances planned pickups with same-day deliveries. | Advantage: Dynamic routing supports 80% of customers demanding same- or next-day deliveries. |

This comparison highlights how each sector adapts its routing approach to meet operational needs. Construction fleets benefit from static routing, which supports predictable schedules and regular site visits. Retail fleets, on the other hand, rely heavily on dynamic routing to meet the increasing demand for rapid deliveries. Logistics fleets often adopt a hybrid approach, combining the predictability of static routing with the flexibility of dynamic solutions to handle same-day delivery requirements.

AI's role in route optimisation also brings environmental benefits. By calculating shorter routes and optimising vehicle loads, companies like UPS have reported saving over 10 million gallons of fuel annually. However, relying too much on AI can backfire if the data inputs are inaccurate or incomplete.

Looking to the future, FedEx anticipates a 50% rise in AI adoption for route optimisation among logistics providers by 2024. Meanwhile, tools such as those offered by GRS Fleet Telematics provide real-time insights into vehicle performance and route efficiency. These solutions allow managers to step in and make adjustments when AI-driven recommendations fall short, ensuring operations remain efficient and responsive.

Conclusion

AI-powered route optimisation is reshaping UK construction fleets, shifting operations from reactive to proactive and data-driven. The results are hard to ignore: delivery times can drop by 15-30%, and fuel consumption may decrease by 10-15%.

The construction sector faces its own set of hurdles, and AI is proving to be a valuable ally. For instance, heavy machinery often sits idle for up to 40% of its operating time. AI can predict equipment needs and streamline deployment across multiple sites, saving time and resources. It doesn’t stop there - predictive maintenance scheduling can help avoid expensive breakdowns. For an industry grappling with tight deadlines and rising fuel costs, these efficiencies can translate into fuel savings of up to 30%. Such advancements directly address challenges like unpredictable site access, equipment coordination, and delivery scheduling that have been highlighted throughout this discussion.

Industry experts echo the transformative potential of AI:

"AI in construction isn't the starting point - it's a multiplier. The real opportunity lies in connecting the systems you already rely on - project management, cost control, scheduling, procurement - to work together supporting faster decisions, earlier risk detection, and stronger performance."

- Craig Zampa, Cole Weinman, Jilson Rodgers, Kimberly Pierce

One of AI's standout strengths is its ability to adapt and learn, continuously refining site access routes and delivery schedules. This gives construction fleets a clear edge over the more predictable routing needs of retail and logistics sectors.

For UK construction firms, the best approach is to start small. Pilot projects can help test the waters and measure ROI before committing to a full-scale rollout. Investing in staff training is just as critical, especially since 33% of businesses report skills gaps when adopting AI. Tools like GRS Fleet Telematics can be invaluable, offering real-time tracking and enabling managers to step in when human oversight is needed.

AI is expected to contribute a staggering £38 billion to the UK economy by 2030. For construction companies, adopting AI now means gaining an edge through reduced costs, faster project completion, and better environmental outcomes. As digital transformation accelerates, AI-driven route optimisation is already proving to be a game-changer for fleet efficiency.

FAQs

How does AI route optimisation help construction fleets overcome their specific challenges compared to logistics and retail fleets?

AI-powered route planning is a game-changer for construction fleets, addressing their specific challenges like multi-stop routing, restricted site access, and time-sensitive deliveries. While logistics or retail fleets often focus on optimising last-mile delivery, construction fleets need to align routes with complex project schedules, equipment availability, and ever-changing site conditions.

Construction sites are notoriously unpredictable, with factors like shifting access routes, fluctuating weather, and evolving delivery needs. AI tools step in by enabling real-time route adjustments, which help cut down delays, lower fuel usage, and ensure materials arrive on time. This level of precision is essential for keeping projects on budget and meeting strict deadlines, making AI-driven route optimisation a vital tool for the construction sector.

How can construction companies successfully implement AI-powered route optimisation, and what challenges should they watch out for?

To make the most of AI-powered route optimisation, construction companies should prioritise integrating real-time traffic data and driver behaviour insights. This combination helps design routes that cut down on delays and keep operations running smoothly. On top of that, using AI to examine construction site layouts and project plans can significantly improve on-site logistics, reducing the time spent on moving materials and boosting productivity.

That said, there are some hurdles to watch out for. Relying too heavily on AI without human input can result in mistakes or unclear accountability. Another concern is the data security risks tied to AI systems. To steer clear of these issues, companies should ensure employees are well-trained, put strong data governance policies in place, and maintain a healthy balance between AI automation and human judgement.

How does AI route optimisation help construction companies achieve sustainability goals, and what environmental benefits can it deliver?

AI-powered route optimisation offers construction companies a practical way to cut down on fuel consumption and vehicle emissions, helping them work towards sustainability goals. By determining the most efficient routes, it reduces unnecessary travel and idling, which directly trims down carbon emissions and saves on fuel.

Beyond transportation, streamlining supply chain operations can also make a big difference. It helps minimise material waste and encourages sustainable practices like reusing resources. These changes result in clear environmental benefits - less resource consumption, reduced waste, and a smaller carbon footprint - allowing businesses to stay on track with their sustainability objectives.